Тормозной суппорт. Устройство и поломки

Самый кошмарный сон любого водителя — это машина с отказавшими тормозами. И хотя мы уже не раз писали о в целом и о , связанных с ее функционированием, не лишним будет снова обратиться к этой теме. Ведь тормоза — основной элемент безопасности автомобиля и тех, кто в нем находится. На этот раз подробнее рассмотрим устройство и работу тормозного суппорта, назначение которого состоит в том, чтобы обеспечить прижимание колодок к диску во время торможения.

Суппорт является основой дискового тормозного механизма. Тормоза такого типа установлены на передних колесах практически всех выпущенных за последние полвека легковых автомобилей. Применение дисковых тормозов на задних колесах долгое время сдерживалось по ряду причин, главной из которых была сложность с организацией стояночного тормоза. Но похоже, эти проблемы остались в прошлом, и уже лет двадцать большинство машин ведущих автопроизводителей выходят с конвейера с задними тормозами дискового типа.

Менее эффективные, но при этом более дешевые, барабанные тормоза все еще используются в бюджетных моделях,а еще в некоторых внедорожниках, для которых имеет значение их грязезащищенность. И, по-видимому, рабочие механизмы барабанного типа останутся актуальными еще довольно долго. Но сейчас речь не о них.

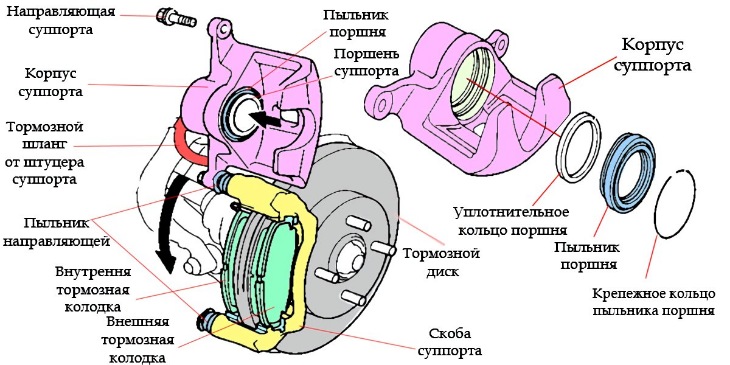

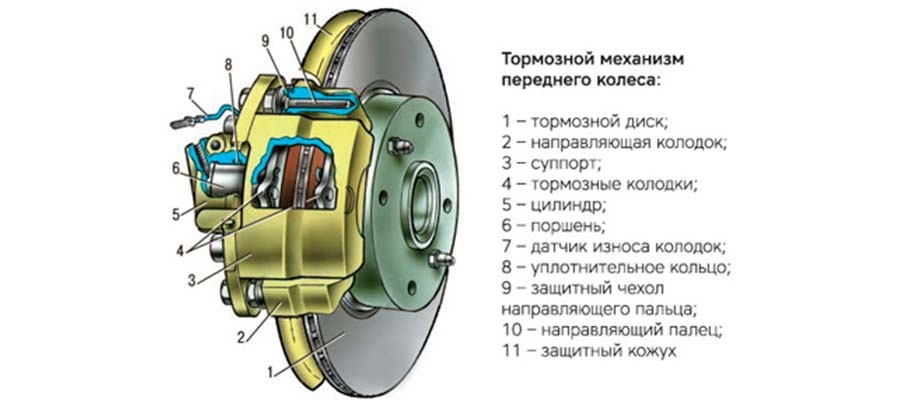

По сути суппорт представляет собой корпус, по форме напоминающий скобу, в котором располагается один или набор тормозных цилиндров. Во процессе торможения гидравлика воздействует на находящиеся в цилиндрах поршни, а те давят на колодки, прижимая их к тормозному диску и замедляя таким образом вращение колеса.

Хотя конструкторы не сидят сложа руки, основной принцип работы тормозного суппорта остается неизменным уже многие годы. Тем не менее можно выделить набор разновидностей данного устройства со своими конструктивными особенностями.

Суппорт обычно изготовлен из чугуна, реже — из сплава на основе алюминия. Его конструкция может иметь неподвижную или плавающую скобу.

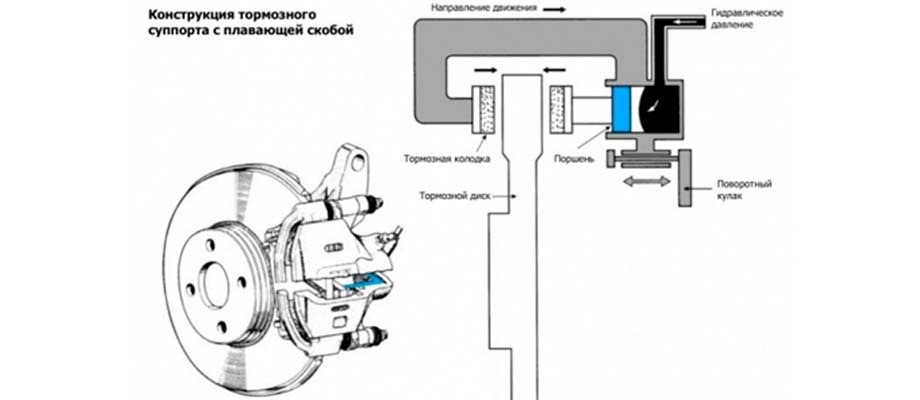

Подвижная скоба способна перемещаться по направляющим, а цилиндр находится с внутренней стороны диска. Нажатая педаль тормоза создает давление в гидравлической системе, которое выталкивает из цилиндра поршень, и тот давит на колодку. Суппорт при этом сдвигается по направляющим в противоположную сторону, прижимая колодку с другой стороны диска.

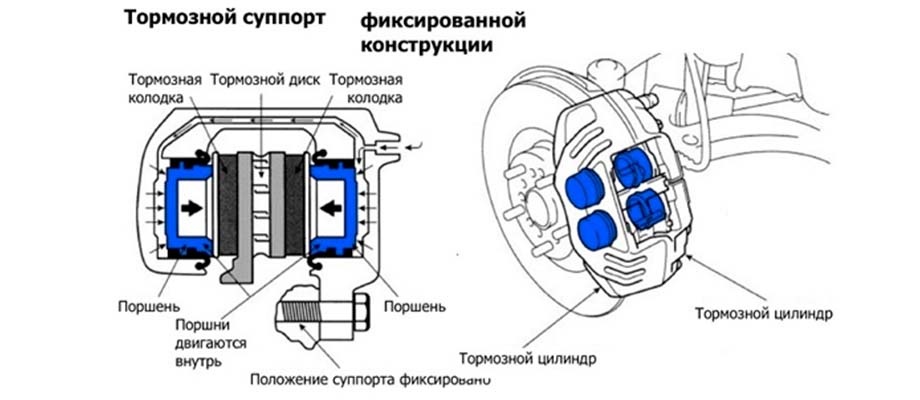

В устройстве с фиксированной скобой цилиндры расположены симметрично относительно тормозного диска и соединены между собой трубкой. Тормозная жидкость одновременно воздействует на оба поршня.

Суппорт статичной конструкции обеспечивает большее тормозное усилие и, соответственно, более эффективное торможение по сравнению с плавающей скобой. Но зазор между диском и колодкой при этом может меняться, что приводит к неравномерному износу колодок. Вариант с подвижной скобой проще и дешевле в изготовлении, поэтому его чаще можно встретить на недорогих моделях.

Толкатель поршня, как правило, непосредственно надавливает на колодку, хотя встречаются конструкции с промежуточным передаточным механизмом.

В каждом суппорте может быть от одного до восьми цилиндров. Варианты с шестью или восемью поршнями встречаются в основном на спортивных моделях автомобилей.

Каждый поршень защищен резиновым пыльником, от состояния которого во многом зависит исправная работа тормозов. Именно попадание влаги и грязи через разорванный пыльник является наиболее частой причиной коррозии и заклинивания поршня. Утечке рабочей жидкости из цилиндра препятствует установленная внутри манжета.

Суппорт, устанавливаемый на задней оси, обычно дополнен механизмом стояночного тормоза. Он может иметь винтовую, кулачковую или барабанную конструкцию.

Винтовой вариант используется в суппортах с одним поршнем, который управляется механическим приводом стояночного тормоза либо гидравликой при обычном торможении.

Внутри цилиндра (2) находится шток (1) с резьбой, на который накручивается поршень (4), и возвратная пружина. Шток соединен с механическим приводом ручника. При задействовании стояночного тормоза шток с поршнем выдвигается на пару миллиметров, колодки прижимаются к тормозному диску и блокируют колесо. Когда ручной тормоз отпускается, поршень посредством возвратной пружины сдвигается в исходное положение, освобождая колодки и разблокируя колесо.

Кулачковый механизм действует аналогичным образом, только здесь на поршень при помощи толкателя давит кулачок. Поворот кулачка осуществляется посредством механического привода ручного тормоза.

В суппорте с несколькими цилиндрами исполнительный механизм ручника обычно выполнен в виде отдельного узла. По сути это барабанный тормоз со своими собственными колодками.

В более продвинутых вариантах для управления стояночным тормозом применяется электромеханический привод.

О том, что с суппортом не всё в порядке, могут говорить косвенные признаки — утечка тормозной жидкости, нужность прилагать дополнительное усилие при нажимании на тормоз или увеличенный свободный ход педали. Из-за разбитых отверстий для направляющих может появиться люфт суппорта, который будет сопровождаться характерным стуком. Из-за заклинивания одного или нескольких поршней колеса будут тормозиться неравномерно, что приведет к заносам во время торможения. На проблемы с суппортом укажет и неодинаковый износ колодок.

Для работы по восстановлению суппорта можно приобрести соответствующий ремонтный комплект. В продаже можно найти ремкомплекты разных производителей и разного качества. При покупке обращайте внимание на состав комплекта, он также может отличаться. Кроме того, можно приобрести отдельные детали или в сборе, если его состояние таково, что ремонтировать не имеет смысла. Обязательной замене при восстановлении суппорта подлежат все резиновые элементы — пыльники, манжеты, уплотнения, сальники.

Если имеются определенные навыки, можно произвести ремонт самостоятельно. Демонтаж и сборка заднего суппорта со встроенным механизмом ручного тормоза могут оказаться достаточно сложными и потребовать специальных инструментов и навыков.

Отдав тормозной шланг перед снятием суппорта, позаботьтесь, чтобы из него не вытекала жидкость. Можно надеть на него какой-нибудь колпачок или заткнуть пробкой.

Если поршень не удается извлечь из цилиндра обычным способом, воспользуйтесь компрессором и продувочным пистолетом, вставив его в отверстие для тормозного шланга. Будьте осторожны — поршень может буквально выстрелить, а заодно брызнет и оставшаяся в цилиндре жидкость. Если компрессор отсутствует, можно попытаться выдавить поршень, нажав педаль тормоза (тормозной шланг, конечно, должен быть подсоединен).

В суппорте с винтовым механизмом ручника поршень не выдавливается, а выкручивается специальным ключом.

Поршень следует очистить от ржавчины, грязи и закоксовавшейся смазки и отшлифовать при помощи наждачной бумаги или мелкого напильника. Бывает, что может потребоваться пескоструйная обработка. На рабочей поверхности поршня не должно быть задиров, царапин и кратеров, возникших из-за коррозии. То же относится и к внутренней поверхности цилиндра. При наличии значительных дефектов поршень лучше заменить. Если вытачивается самодельный стальной поршень, его нужно будет хромировать.

Если суппорт с плавающей скобой, особое внимание следует уделить направляющим. Они нередко закисают из-за дефекты пыльника, нерегулярного смазывания или при использовании некорректной смазки. Их нужно тщательно очистить и отшлифовать,а еще убедиться в отсутствии деформации, чтобы ничто не препятствовало свободному ходу скобы. И не забудьте прочистить отверстия для направляющих.

В зависимости от состояния, возможно, потребуется заменить запорную арматуру гидравлики, штуцер прокачки, соединительные трубки (в устройствах с несколькими поршнями),а еще крепежные детали.

При сборке восстановленного механизма обязательно смажьте поршень и направляющие,а еще внутреннюю поверхность пыльника. Использовать нужно только специальную смазку для суппортов, сохраняющую свои рабочие параметры в широком диапазоне температур.

После сборки не забудьте прокачать гидравлику, удалив из системы воздух. диагностируйте отсутствие утечек и уровень тормозной жидкости.

Если в тормозной системе возникли неполадки, не затягивайте с их устранением. И дело не только в безопасности и риске попасть в аварию, но и в том, что одна проблема может потянуть за собой другие. К примеру, заклинивший суппорт способен вызвать перегрев и выход из строя ступичного подшипника. Неодинаковое торможение будет приводить к неравномерному износу покрышек. Закисший поршень может постоянно прижимать колодку к тормозному диску, вызывая его перегрев и преждевременный износ. Возможны и другие неприятности, которых можно избежать, если следить за состоянием тормозных механизмов,а еще не забывать регулярно менять рабочую жидкость.