Устройство и принцип работы системы ABS

Содержание

- Что такое антиблокировочная система

- История

- Назначение антиблокировочной системы

- Устройство АБС

- Принцип работы АБС

- Типы антиблокировочных систем

- Режимы работы

- Особенности управления автомобилем с АБС

- Результативность торможения

- Эксплуатация ABS

- Эффективность работы АБС

- Какие бывают неисправности

- Преимущества и недостатки системы

- Видео на тему

- Вопросы и ответы:

В комплект активной безопасности современных автомобилей входят различные помощники и системы, позволяющие либо предотвратить аварийную ситуацию, либо максимально снизить человеческие травмы во время ДТП.

Среди таких элементов – антиблокировочная система. Что это такое? Как устроена современная ABS? Принцип работы АБС и как управлять автомобилем, когда эта система включена? Ответы на эти вопросы находятся в данном обзоре.

Что такое антиблокировочная система

Под антиблокировочной системой подразумевается совокупность электрогидравлических элементов, которые устанавливаются в ходовую часть автомобиля и связаны с его тормозами.

Она обеспечивает лучшее сцепление с дорожным покрытием, предотвращая полную остановку колес в процессе торможения на нестабильном дорожном покрытии. Такое часто происходит на льду или мокрых дорогах.

История

Впервые данная разработка была представлена общественности в 1950-х гг. Однако ее нельзя было назвать концепцией, потому что данную идею разрабатывали еще в начале ХХ века. Так, инженер Дж.Френсис в 1908-м году продемонстрировал работу своего «Регулятора», который предотвращал проскальзывание колес в рельсовом транспорте.

Подобную систему разрабатывал и механик и инженер Г. Вуазен. Он пытался создать систему тормозов для самолетов, которая самостоятельно регулировала гидравлическое воздействие на тормозные элементы так, чтобы колеса летательного аппарата не скользили по взлетно-посадочной полосе в результате торможения. Эксперименты с модификациями таких устройств он выполнял в 20-х годах ХХ века.

Ранние системы

Конечно, как и в случае всех первых разработок любых изобретений, изначально система, предотвращающая блокировку, имела сложное и примитивное строение. Так, вышеупомянутый Габриэль Вуазен в своих разработках использовал маховик и гидроклапан, подсоединенный к магистрали тормозов.

Работала система по такому принципу. Маховик крепился к барабану на колесе и вращался вместе с ним. Когда нет заноса, барабан и маховик вращаются с одинаковой скоростью. Как только колесо останавливается, барабан замедляется вместе с ним. Из-за того, что маховик продолжает вращаться, приоткрывался клапан гидравлической магистрали, снижая усилие на тормозной барабан.

Такая система зарекомендовала себя большей стабильностью транспортного средства, так как в случае заноса водитель инстинктивно еще сильнее нажимает на тормоза, вместо того, чтобы выполнять эту процедуру плавно. Данная разработка повысила эффективность торможения на 30 процентов. Еще один положительный результат – меньше лопнувших и стертых шин.

Однако должное признание система получила благодаря усилиям немецкого инженера Карла Весселя. Его разработку запантентовали в 1928-м. Несмотря на это установка не применялась на транспорте по причине значительных недоработок в ее устройстве.

Действительно рабочая антискользящая система тормозов использовалась в авиации в начале 50-х годов. А в 1958-м комплект Maxaret впервые был установлен на мотоцикл. Модель Royal Enfield Super Meteor был оснащен рабочей антиблокировочной системой. За работой системы следила Дорожная лаборатория. Исследования показали, что данный элемент тормозной системы значительно снизит аварии на мотоциклах, большая часть которых происходят именно из-за заноса при блокировке колеса во время торможения. Несмотря на такие показатели, главный директор технического отдела мотокомпании не одобрил массовое производство АБС.

В автомобилях механическая система, предотвращающая скольжение колес, применялась лишь в некоторых моделях. Одной из них является Ford Zodiac. Причиной такой ситуации являлась низкая надежность устройства. Лишь, начиная с 60-х гг. электронная антиблокировочная система нашла свое применение в известных самолетах Concorde.

Современные системы

Принцип электронной модификации перенял инженер исследовательского центра Fiat и назвал изобретение Antiskid. Разработка была продана компании Бош, после чего и получила название ABS.

В 1971-м году автомобильный производитель Chrysler представил полноценную и эффективную систему, которая управлялась компьютером. Похожую разработку годом раньше применил американский Ford в своем культовом Lincoln Continental. Постепенно эстафету приняли и другие ведущие автопроизводители. К середине 70-х годов большинство автомобилей с задним приводом имели электронную антиблокировочную систему на ведущих колесах, а некоторые авто оснащались модификацией, работающей на всех четырех колесах.

С 1976 года подобная разработка начала применяться на грузовом транспорте. В 1986-м система получила название EBS, так как работала полностью на электронике.

Назначение антиблокировочной системы

Нередко при торможении на нестабильной поверхности (лед, укатанный снег, вода на асфальте) водитель наблюдает совсем не ту реакцию, чем ожидал – вместо замедления транспорт становится неуправляемым и совсем не останавливается. Причем более сильное нажатие педали тормоза не помогает.

Когда резко срабатывают тормоза, колеса блокируются, а из-за плохого сцепления с трассой они просто перестают вращаться. Чтобы такой эффект не происходил, нужно плавно задействовать тормоза, однако в экстренной ситуации водитель неконтролируемо жмет педаль в пол. Некоторые профессионалы на нестабильном покрытии для замедления автомобиля несколько раз нажимают и отпускают педаль тормоза. Благодаря этому колеса не блокируются и не идут юзом.

Насколько печально это ни звучит, но такой навык освоить не каждому удается, а некоторые даже не считают нужным это делать, а просто покупают дорогие профессиональные шины с большей надежностью сцепления. Для таких случаев производители и оснащают большинство своих моделей антиблокировочной системой.

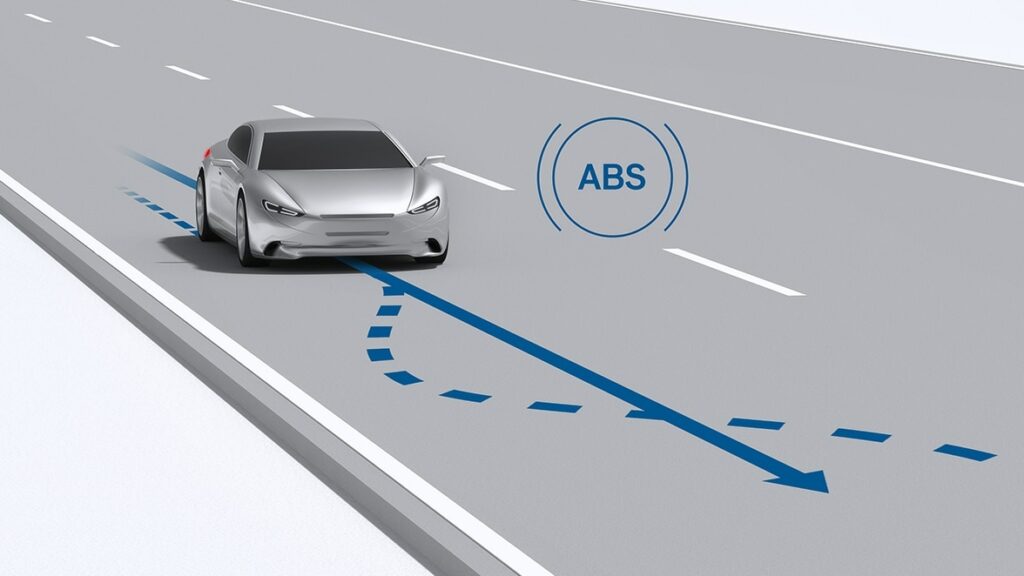

АБС позволяет сохранить контроль над автомобилем в нештатной ситуации, предотвращая полную остановку колес во время нажатия на тормоз.

Устройство АБС

В устройство современной АБС входит небольшое количество элементов. Она состоит из:

- Датчика вращения колеса. Такие устройства устанавливаются на все колеса. Электронный блок управления анализирует параметры, которые поступают от каждого из таких датчиков. На основании полученных данных ЭБУ самостоятельно активирует/деактивирует систему. Чаще всего такие следящие устройства работают по принципу датчика Холла;

- Электронного блока управления. Без него она работать не будет, так для сбора информации и активации системы нужны «мозги». В некоторых автомобилях каждая система имеет собственный эбу, однако часто производители устанавливают один блок, который обрабатывает все элементы системы активной безопасности (курсовая устойчивость, АБС, антипробуксовочная и т.д.);

- Исполнительных устройств. В классическом исполнении эти элементы являют собой блок с набором клапанов, аккумуляторов давления, насосов и т.д. Иногда в технической литературе можно встретить название гидромодулятор, которое применяется к данным элементам.

Особенностью системы АБС является то, что ее можно подключить к тормозной системе даже не самого нового автомобиля. Чаще всего они представляют собой комплект, который просто подсоединяется к тормозной магистрали и электросистеме машины.

Принцип работы АБС

Условно работа антиблокировочной системы делится на 3 этапа:

- Блокировка колес – эбу посылает сигнал для активации системы;

- Срабатывание исполнительного устройства – гидравлический блок меняет давление в системе, что приводит к разблокировке колес;

- Деактивация системы при восстановлении вращения колес.

Стоит учесть, что весь процесс контролируется алгоритмами, заложенными в программное обеспечение блока управления. Надежность системы заключается в том, что ее срабатывание происходит еще перед тем, как колеса потеряют сцепление с дорогой. Аналог, который работает только на основе данных о вращении колес, имел бы более простое устройство и принцип действия. Однако такая система работала бы ничем не лучше первых разработок Габриеля Вуазена.

По этой причине АБС реагирует не на изменение скорости вращения колес, а на силу нажатия педали тормоза. Другими словами, система срабатывает заранее, как бы предупреждая возможный занос, определяя как скорость вращения колес, так и силу нажатия на педаль. Блок управления рассчитывает возможное скольжение, и активирует исполнительное устройство.

Срабатывает система по следующему принципу. Как только возникает экстренная ситуация (водитель резко нажал на педаль тормоза, но колеса еще не заблокировались), гидромодулятор получает от блока управления сигнал и перекрывает два клапана (на впуске и на выпуске). Благодаря этому давление в магистрали стабилизируется.

Затем исполнительное устройство выполняет пульсацию тормозной жидкости. В этом режиме гидромодулятор может либо обеспечить медленное проворачивание колеса, либо самостоятельно повышать/понижать давление тормозной жидкости. Эти процессы зависят от модификации системы.

Когда срабатывает АБС, водитель сразу это почувствует по частой пульсации, которая передается также и на педаль. О том, активна ли система или нет, можно узнать по ласпочке на кнопке активации. Сам принцип работы системы повторяет навык опытных автомобилистов, только делает это намного быстрее – около 20 раз за секунду.

Типы антиблокировочных систем

Благодаря усовершенствованию систем активной безопасности на рынке автозапчастей можно найти четыре варианта ABS:

- Одноканальный. Сигнал к блоку управления и обратно одновременно подается по единой проводной магистрали. Чаще всего ею оснащаются переднеприводные машины, и то только на ведущие колеса. Такая система срабатывает независимо от того, какое колесо заблокировалось. Данная модификация имеет один клапан на входе гидромодулятора и один на выходе. Также в ней используется один датчик. Эта модификация самая неэффективная;

- Двухканальный. В таких модификациях используется так называемая бортовая система. В ней управление правой стороной производится отдельно от левой. Данная модификация зарекомендовала себя неплохой надежностью, так как при возникновении экстренной ситуации машину сносит на обочину. В этом случае колеса правого и левого борта оказываются на разной поверхности, поэтому и АБС должна подавать разные сигналы на исполнительные устройства;

- Трехканальный. Эту модификацию можно смело назвать гибридом первой и второй. В таких АБС задние тормозные колодки управляются по одному каналу, как в первом случае, а передние колеса работают по принципу бортовой АБС;

- Четырехканальный. На сегодняшний день это самая эффективная модификация. В ней для каждого колеса предусмотрен индивидуальный датчик и гидромодулятор. ЭБУ контролирует вращение каждого колеса, благодаря чему обеспечивается максимальное сцепление с дорогой.

Режимы работы

Работа современной системы ABS может осуществляться в трех режимах:

- Режим нагнетания. Это стандартный режим, который используется во всех классических разновидностях тормозной системы. В антиблокировочной системе выпускной клапан закрыт, а впускной – открыт. Благодаря этому в контуре при нажатии на педаль тормоза начинает перемещаться жидкость, приводящая в движение тормозной цилиндр каждого колеса.

- Режим удержания. В этом режиме блок управления фиксирует, что одно из колес замедляется намного быстрее других. Чтобы предотвратить потерю контакта с дорогой, АБС блокирует впускной клапан магистрали конкретного колеса. Благодаря этому усилие на суппорт не оказывается, но при этом остальные колеса продолжают замедляться.

- Режим сброса давления. Этот режим активируется, если предыдущий не смог справиться с возникшей блокировкой колеса. В этом случае впускной клапан магистрали продолжает быть закрытым, а выпускной наоборот – открывается, чтобы сбросилось давление в данном контуре.

Эффективность торможения при включенной системе ABS зависит от того, насколько эффективно она переходит с одного режима на другой. В отличие от стандартной тормозной системы, при включенной ABS нет необходимости многократно нажимать на тормоз, чтобы колеса не потеряли сцепление с дорогой. В этом случае водителю нужно полностью нажать на педаль тормоза. Всю остальную работу сделает сама система.

Особенности управления автомобилем с АБС

Какой бы надежной ни была тормозная система в автомобиле, она не исключает необходимость во внимательности водителя. Антиблокировочная система имеет свои особенности. Если их не учитывать, то авто может потерять стабильность. Вот основные правила в экстренных ситуациях:

- Если автомобиль оснащен простой АБС, то чтобы она активировалась, нужно резко нажать педаль тормоза. Некоторые современные модели оснащаются ассистентом торможения. В этом случае блок управления определяет возможность потери сцепления с дорогой и включает этого помощника. Даже при несильном нажатии на педаль система активируется и самостоятельно повысит давление в магистрали до нужного параметра;

- Как уже было сказано, при активации системы, педаль тормоза пульсирует. Неопытный водитель сразу думает, что с автомобилем что-то случилось и решает отпустить тормоз;

- При движении на шипованной резине АБС лучше отключить, так как шипы в покрышках имеют свою эффективность как раз тогда, когда колесо блокируется;

- Во время передвижения по рыхлому снегу, песку, гравию и т.п. АБС также скорее бесполезна, чем помогает. Дело в том, что заблокированное колесо перед собой собирает небольшой бугор из материала, из которого состоит дорога. Тем самым создается дополнительное сопротивление скольжению. Если колесо будет проворачиваться, такого эффекта не будет;

- Также система АБС может неадекватно срабатывать при быстрой езде по неровной поверхности. Даже при незначительном торможении колесо, оказавшееся в воздухе, быстро остановится, что будет провоцировать блок управления активировать устройство, когда этого не требуется;

- Если АБС включена, то при выполнении маневра следует использовать и тормоза. В обычном автомобиле это лишь спровоцирует занос или недостаточную поворачиваемость. Однако машина с АБС более охотно слушается руля при активной системе антиблокировки.

Результативность торможения

Система АБС не только сокращает тормозной путь, но и обеспечивает максимальный контроль над транспортным средством. По сравнению с автомобилем, не оснащенным данной системой, транспорт с ABS однозначно будет более эффективно тормозить. Это доказывать не нужно. Помимо меньшего тормозного пути в такой машине более равномерно будут изнашиваться покрышки, так как тормозные усилия распределяются равномерно на все колеса.

Особенно по достоинству оценят данную систему водители, которые часто ездят по дорогам с нестабильным покрытием, например, когда асфальт мокрый или скользкий. Хотя ни одна система не способна полностью устранить все ошибки водители защитить от экстренной ситуации (внимательность и предусмотрительность водителя никто не отменял), тормоза с АБС делают транспортное средство более предсказуемым и управляемым.

Учитывая высокую результативность торможения, многие специалисты рекомендуют новичкам привыкать к езде на транспорте с системой ABS, что повысит безопасность на дороге. Конечно, если водитель будет нарушать правила обгона и скоростные режимы, система АБС не сможет предотвратить последствия таких нарушений. Например, какой бы эффективной ни была система, она бесполезна, если водитель не переобул машину на зиму, и продолжает ездить на летних шинах.

Эксплуатация ABS

Современная система АБС считается надежной и стабильной системой. Она может исправно работать длительное время, но она все равно нуждается в правильной эксплуатации и своевременном обслуживании. Блок управления редко когда дает сбой.

Но если взять датчики вращения колес, то это самое уязвимое место в такой системе. Причина в том, что датчик определяет скорость вращения колеса, а значит, он должен быть установлен в непосредственной близости с ним – на ступице колеса.

Когда машина едет по грязи, луже, песку или мокрому снегу, датчик сильно загрязняется и может либо быстро выйти из строя, либо давать некорректные значения, что приведет к нестабильной работе системы. При низком заряде аккумулятора или напряжении в бортовой системе авто, блок управления отключит систему из-за слишком низкого напряжения.

Если система вышла из строя, автомобиль не лишится тормозов. Просто в таком случае водителю нужно уметь тормозить на нестабильной дороге при помощи классической тормозной системы.

Эффективность работы АБС

Итак, система ABS позволяет более безопасно выполнять экстренное торможение, а также дает возможность выполнять маневры при полностью нажатой педали тормоза. Благодаря этим двум важным параметрам данная система является неотъемлемой в комплектации автомобиля с передовой системой активной безопасности.

Наличие ABS необязательно для опытного автомобилиста. Но вот новичку в первые пару лет приходится осваивать множество разных навыков, поэтому предпочтительно, чтобы в машине такого водителя было несколько систем, обеспечивающих подстраховку.

Опытный водитель без труда (особенно если на своей машине он ездит уже много лет) сможет контролировать момент срыва колес, изменяя усилия на педаль тормоза. Но даже при наличии большого водительского стажа многоканальная система может составить конкуренцию такому навыку. Причина в том, что водитель не способен контролировать усилие на отдельном колесе, а АБС может (одноканальная система работает, как опытный водитель, изменяя усилия на всю тормозную магистраль).

Но систему ABS нельзя считать панацеей в экстренных ситуациях на любой дороге. Например, если машину занесло на песке или в рыхлом снегу, то она наоборот станет причиной увеличенного тормозного пути. На такой дороге наоборот будет более полезна блокировка колес – они зарываются в грунт, что ускоряет торможение. Чтобы автомобиль был универсален на любом типе дорожного покрытия, производители современных моделей авто оснащают свою продукцию отключаемой АБС.

Какие бывают неисправности

Что касается надежности антиблокировочной системы, то это одна из самых надежных систем автомобиля. Ее элементы редко когда выходят из строя, а связано чаще всего это с нарушением правил эксплуатации и обслуживания. Все электронные части надежно защищены от перегрузок предохранителями и реле, поэтому блок управления не даст сбоя.

Самые распространенные неисправности системы – выход из строя датчиков колес, так как они расположены в таких местах, в которых крайне сложно исключить попадание на них воды, пыли или грязи. Если подшипник ступицы сильно люфтит, то датчики будут работать со сбоями.

Другие неполадки уже связаны больше с сопутствующими системами автомобиля. Примером тому является снижение напряжения в электрической сети машины. В этом случае ABS отключится из-за сработавшего реле. Та же проблема может наблюдаться при скачках напряжения в сети.

Если антиблокировчная система самостоятельно отключилась, не стоит паниковать – машина просто будет себя вести, как если бы в ней не было АБС.

Ремонт и обслуживание тормозной системы авто с ABS имеет свои особенности. Например, прежде чем менять тормозную жидкость, необходимо при выключенном зажигании несколько раз нажать на тормоз и отпустить (около 20 раз). Это сбросит давление в аккумуляторе гидроблока. О том, как правильно заменить тормозную жидкость и затем прокачать систему, читайте в отдельной статье.

О неисправности АБС водитель сразу узнает по соответствующему сигналу на приборной панели. Если сигнальная лампочка то загорится, то погаснет – следует обратить внимание на контакт датчиков колес. Скорее всего, из-за потери контакта блок управления не получает сигнал от этих элементов, и сигнализирует о неисправности.

Преимущества и недостатки системы

Много о преимуществах антиблокировочной системы не придется говорить, так как основное ее достоинство – в стабилизации автомобиля в случае проскальзывания колес во время торможения. Вот какие преимущества есть у автомобиля с такой системой:

- Во время дождя или на гололеде (скользкий асфальт) машина показывает большую стабильность и управляемость;

- При выполнении маневра можно активно пользоваться тормозами для лучшего отклика рулевого управления;

- На гладкой поверхности длина тормозного пути меньше, чем у машины без АБС.

Один из недостатков системы – она плохо справляется с мягким дорожным покрытием. В этом случае тормозной путь будет меньшим, если колеса заблокируются. Хотя последние модификации ABS уже учитывают особенности грунта (на селекторе трансмиссии выбирается соответствующий режим), и подстраиваются под данную дорожную ситуацию.

Дополнительно о принципе работы АБС и ее преимуществах рассказывается в следующем видео:

Видео на тему

В завершение обзора предлагаем небольшое видео о том, как тормозить на машине с АБС и без нее:

Вопросы и ответы:

Что означает антиблокировочная тормозная система? Это электронная система, которая предотвращает блокировку колес во время торможения путем кратковременного снижения давления тормозной жидкости.

Для чего нужна антиблокировочная система? Если резко нажать тормоз, колеса могут потерять сцепление с дорогой и машина будет неуправляемой. ABS обеспечивает импульсное торможение, позволяя колесам сохранять сцепление.

Как работает антиблокировочная система? Электроника следит за блокировкой колес и их пробуксовкой. Благодаря клапанам на каждом тормозном суппорте регулируется давление ТЖ на конкретный поршень.

Как тормозить при антиблокировочной системе? В машинах с ABS нужно нажать педаль до упора, а система сама обеспечит импульсное торможение. Нет необходимости нажимать/отпускать педаль во время торможения.

4 комментария

ayele

full pdf

Дмитрий 25346@mail.ru

Можно вопрос: Автомобиль (оборудованный АБС + EBD с диагональным разделением контуров) двигается по сухому асфальту, Будет ли происходить увод автомобиля влево при резком торможении при условиях:

а. при торможении произошла разгерметизация привода тормоза переднего правого колеса;

б. разгерметизация привода тормоза переднего правого колеса произошла ранее, жидкость в контуре отсутствовала

Аноним

rota e perparme majtas ri frenato

tuula

Onko renault lakunan abs ohjaysyksikkö sama hydraaliyksikkö tarkoittaako samaa osaa autossa palaa abs valo