Устройство и принцип работы компрессора кондиционера

Содержание

Автомобильный кондиционер является довольно сложной и дорогостоящей системой. Он обеспечивает охлаждение воздуха в салоне, поэтому его поломка, особенно летом, вызывает у водителей массу неудобств. Ключевым компонентом в системе кондиционирования является компрессор кондиционера. Рассмотрим подробнее его устройство и принцип работы.

Как работает кондиционер в автомобиле

Компрессор сложно представить в отрыве от всей системы, поэтому вначале кратко рассмотрим принцип работы системы кондиционирования. Устройство автомобильного кондиционера не отличается от устройства холодильных установок или бытовых кондиционеров. Это замкнутая система с магистралями, в которых находится хладагент. Он циркулирует по системе, поглощая и отдавая тепло.

Компрессор выполняет основную работу: отвечает за циркуляцию хладагента по системе и делит ее на контуры высокого и низкого давления. Сильно разогретый хладагент в газообразном состоянии и под высоким давлением поступает от нагнетателя в конденсер. Затем он превращается в жидкость и проходит через ресивер-осушитель, где из него выходит вода и мелкие загрязнения. Далее, хладагент попадает в расширительный клапан и испаритель, который представляет собой небольшой радиатор. Там происходит дросселирование хладагента, сопровождающееся сбросом давления и понижением температуры. Жидкость вновь переходит в газообразное состояние, охлаждается и конденсируется. Вентилятор гонит охлажденный воздух в салон автомобиля. Далее, уже газообразное вещество с низкой температурой поступает обратно в компрессор. Цикл повторяется вновь. Часть системы с горячим хладагентом относится к зоне высокого давления, а с холодным – к зоне низкого давления.

Виды, устройство и принцип работы компрессора

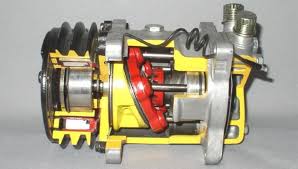

Компрессор представляет собой нагнетатель вытеснительного типа. Он начинает свою работу после включения кнопки кондиционера в салоне автомобиля. Устройство имеет постоянное ременное соединение с двигателем (привод) через электромагнитную муфту, которая позволяет запускать установку, когда это необходимо.

Нагнетатель всасывает охлажденный хладагент в газообразном состоянии из зоны низкого давления. Далее, за счет сжатия повышается давление и температура хладагента. Это главные условия для его расширения и дальнейшего охлаждения в расширительном клапане и испарителе. Для повышения срока службы составных частей компрессора используется специальное масло. Часть его остается в нагнетателе, другая часть растекается по системе. На компрессоре размещен предохранительный клапан, который защищает установку от превышения давления сверх нормы.

Различают следующие виды компрессоров в климатических установках:

- аксиально-поршневые;

- аксиально-поршневые с вращающимся наклонным диском;

- лопастные (роторные);

- спиральные.

Наиболее широкое распространение получили аксиально-поршневые и аксиально-поршневые нагнетатели с наклонным вращающимся диском. Это наиболее простой и надежный вариант устройства.

Аксиально-поршневой нагнетатель

Приводной вал компрессора приводит в движение наклонный диск, который, в свою очередь, образует возвратно-поступательное движение поршней в цилиндрах. Поршни двигаются параллельно валу. Количество поршней может отличаться в зависимости от модели и конструктивного решения. Их может быть от 3 до 10. Таким образом, формируется такт работы. Клапана открываются и закрываются. Происходит всасывание и нагнетания хладагента.

Мощность климатической установки зависит от максимальной частоты вращения компрессора. Часто производительность зависит от скорости двигателя. Диапазон частоты вращения нагнетателя находится от 0 до 6 000 об/мин.

Чтобы убрать зависимость работы компрессора от скорости работы двигателя, используются компрессоры с изменяемым рабочим объемом. Это достигается путем применения вращающегося наклонного диска. Угол наклона диска меняется с помощью пружин, что корректирует производительность всей климатической установки. В компрессорах с постоянным аксиальным диском регулировка происходит в результате отключения и включения электромагнитной муфты.

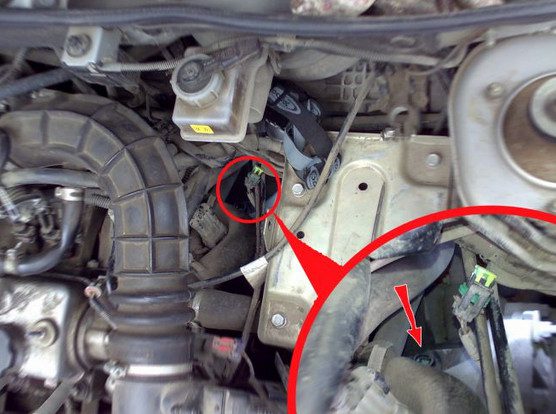

Привод и электромагнитная муфта

Электромагнитная муфта обеспечивает связь работающего двигателя и компрессора во время включения кондиционера. Муфта состоит из следующих компонентов:

- ременной шкив на подшипнике;

- электромагнитная катушка;

- подпружиненный диск со ступицей.

Двигатель посредством ременного соединения приводит в движение шкив. Подпружиненный диск соединен с приводным валом, а электромагнитная катушка с корпусом нагнетателя. Между диском и шкивом имеется небольшой зазор. Когда включается кондиционер, электромагнитная катушка создает магнитное поле. Подпружиненный диск и вращающийся шкив соединяются. Компрессор начинает свою работу. Когда кондиционер выключается, пружины отводят диск от шкива.

Возможные неисправности и режимы отключения компрессора

Как уже было сказано, климатическая установка в автомобиле – это сложная и дорогая система. Ее “сердцем” является компрессор. Наиболее частые поломки кондиционера связаны именно с этим элементом. Проблемами могут стать:

- неисправность электромагнитной муфты;

- выход из строя подшипника шкива;

- утечка хладагента;

- перегорание предохранителя.

Подшипник шкива испытывает большие нагрузки и часто выходит из строя. Это обусловлено его постоянной работой. Поломку можно определить по непривычному звуку.

Именно компрессор кондиционера выполняет большую часть механической работы в климатической установке, поэтому он нередко выходит из строя. Этому также способствуют плохие дороги, неисправность других узлов, неправильная работа электрооборудования. Для ремонта потребуются специальные знания и умения. Лучше обратится в сервисный центр.

Также есть некоторые режимы, при которых происходит отключение компрессора, предусмотренное системой:

- очень высокое (выше 3 МПа) или низкое (ниже 0,1 МПа) давление внутри нагнетателя и магистралей (показывают датчики давления, пороговые значения могут отличаться в зависимости от производителя);

- низкая температура воздуха снаружи;

- чрезмерно высокая температура охлаждающей жидкости (выше 105˚C);

- температура испарителя ниже примерно 3˚C;

- открытие дроссельной заслонки более 85%.

Чтобы более точно определить причину неисправности, можно воспользоваться специальным сканером или обратиться за диагностикой в сервисный центр.