Тест драйв история автомобильных шин III: Химики в движении

Шина — это высокотехнологичный продукт, ставший результатом десятилетий эволюции.

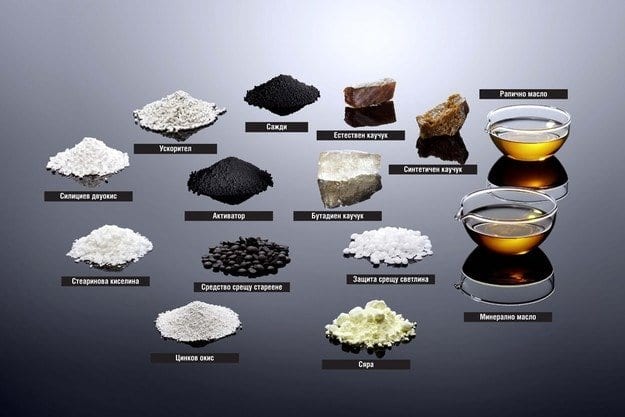

Вначале ни производители резины, ни химики не знали точного химического состава и молекулярной структуры сырья, с которым они работают, а шины имеют довольно сомнительное качество. Их основная проблема — легкое стирание и износ, а значит, очень короткий срок службы. Незадолго до начала Первой мировой войны химики обнаружили, что добавление газообразной сажи в качестве вещества в структуру значительно увеличивает прочность, эластичность и стойкость к истиранию. Сера, сажа, цинк, а также так называемый диоксид кремния или хорошо известный кварц (диоксид кремния), который недавно использовался в качестве добавки, играют значительную роль в изменении химической структуры резины и улучшении ее свойств, а их использование с такая цель восходит к разным периодам развития технологий производства шин. Но, как мы уже сказали, вначале молекулярная структура шины была полной загадкой.

Однако на самом деле еще в 1829 году Майкл Фарадей описал основной строительный блок каучука с химической формулой C5H8, или, другими словами, изопрен. В 1860 году химик Уильямс получил жидкость той же формулы. В 1882 году был впервые получен синтетический изопрен, а в 1911 году химики Фрэнсис Мэтьюз и Карл Харрис независимо друг от друга обнаружили, что изопрен может быть полимеризован — процесс, лежащий в основе успешного создания искусственного каучука. На самом деле успех ученых наступает в то время, когда они отказываются полностью копировать химическую формулу натурального каучука.

Стандарт Ойл и IG Farben

Еще в 1906 году специалисты немецкой компании Bayer запустили мощную программу по производству синтетического каучука. Во время Первой мировой войны из-за нехватки натурального сырья началось производство шин на основе так называемого метилового каучука, созданного компанией Bayer. Однако после Первой мировой войны он был прекращен из-за его высокой конечной цены и доступного более дешевого натурального продукта. Однако в 20-х годах снова возникла нехватка натурального каучука, что привело к началу интенсивных исследований в СССР, США и Германии.

Еще весной 1907 года Фриц Хоффманн и доктор Карл Кутель, используя каменноугольную смолу, разработали технологию получения исходных продуктов изопрена, метилизопрена и газообразного бутадиена, и следующим этапом в развитии деятельности стала полимеризация молекул этих веществ. После Первой мировой войны исследователи из гигантского концерна IG Farben, в который теперь входит и компания Bayer, сосредоточились на полимеризации бутадиенового мономера и сумели создать синтетический каучук под названием Buna — сокращение первых букв бутадиена и натрия. В 1929 году концерн уже производил шины из так называемой Buna S, в которую добавлялась сажа. Du Pont, в свою очередь, синтезировал неопрен, тогда еще называемый дюпреном. В 30-х годах химики Standard Oil из Нью-Джерси, предшественника Exxon, преуспели в разработке процесса синтеза бутадиена с использованием нефти в качестве основного продукта. Парадокс в данном случае заключается в том, что сотрудничество American Standard с немецкой IG Farben позволяет американской компании создать процесс производства синтетического каучука, аналогичный Buna S, и стать серьезным фактором в упомянутом соглашении для решения проблемы с резиной. США во время Второй мировой войны. В целом, однако, в исследованиях и разработках многофункциональных заменителей шин в стране доминируют четыре основные компании: Firestone Tire & Rubber Company, BF Goodrich Company, Goodyear Tire & Rubber Company, United States Rubber Company (Uniroyal). Их совместные усилия во время войны были необходимы для создания качественных синтетических продуктов. В 1941 году они и Standard подписали соглашение об обмене патентами и информацией под юрисдикцией компании Rubber Reserve Company, основанной Рузвельтом, и стали примером того, как крупный бизнес и государство могут объединиться во имя военных поставок. Благодаря огромному труду и государственным средствам в чрезвычайно короткие сроки был построен 51 завод по производству мономеров и синтезируемых ими полимеров, необходимых для производства синтетических шин. Технология, используемая для этой цели, основана на производственном процессе Buna S, потому что он может лучше всего смешивать натуральный и искусственный каучук и использовать доступные обрабатывающие машины.

В Советском Союзе во время войны 165 колхозов выращивали два вида одуванчиков, и, хотя производство было неэффективным, а урожайность с единицы площади была низкой, произведенный каучук способствовал победе. Сегодня этот одуванчик считается одной из возможных альтернатив гевее. В этот продукт добавлен синтетический бутадиен или так называемый сопрен, созданный Сергеем Лебедевым, в котором в качестве сырья используется спирт, полученный из картофеля.

(следовать)

Текст: Георгий Колев