Chii chiri uye sei ma sensors einjini lubrication system anoshanda?

Zviri mukati

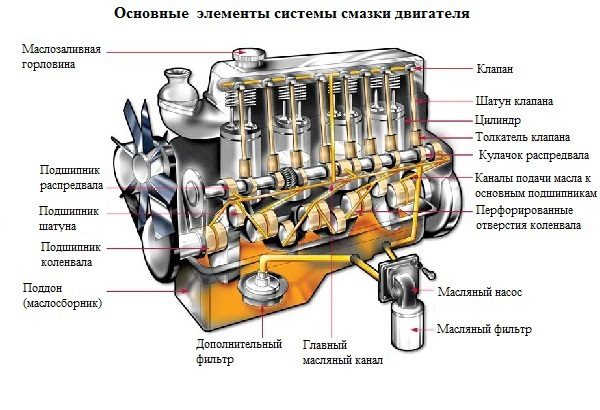

Kune chaiyo yekushanda kweinjini lubrication system, iyo yakazara yakaoma sensors inoshandiswa. Vanokutendera iwe kudzora mwero (vhoriyamu), kumanikidza, mhando (degree rehutachiona) uye tembiricha yemafuta enjini. Dzemotokari dzazvino dzinoshandisa zvese zvemagetsi uye emagetsi (emagetsi) maseru. Basa ravo guru nderekurekodha chero kutsauka mune mamiriro ehurongwa kubva kune zvakajairwa parameter uye nekupa iyo inoenderana ruzivo kune zvinongedzo zvemota dashibhodhi.

Chinangwa uye chishandiso chemafuta ekumanikidza sensor

Oiri yekumanikidza sensors ari pakati pezvakanyanya kukosha muhurongwa. Ivo ndevamwe vekutanga kuita kune zvidiki zvisina kufanira zvinoshanda muinjini. Pressure sensors inogona kuwanikwa munzvimbo dzakasiyana: padyo nesilinda musoro, padyo nebhandi renguva, padhuze nepombi yemafuta, pane mabhureki kune iyo firita, nezvimwe.

Mhando dzakasiyana dzeinjini dzinogona kuve neiri kana maviri emafuta ekumanikidza maseru.

Yekutanga ndeye emergency (yakaderera kumanikidza), iyo inosarudza kana paine kumanikidza muhurongwa, uye kana isipo, zvinoratidzwa nekuvhenekesa mwenje wekusashanda pane radhiboardi yemotokari.

Chechipiri kudzora, kana kumanikidza kwakazara.

Kana iyo "tsvuku yemafuta inogona" padhibhodhi yemotokari ichivhenekera - kumwe kufambira mberi pamotokari kunorambidzwa! Kufuratira ichi chinodikanwa kunogona kutungamira kumatambudziko akakomba muchimiro cheinjini yekugadzirisa.

Cherekedza kune vatyairi. Kudzora marambi padhibhodhi ane mavara akasiyana nechikonzero. Chero tsvuku tsvuku zviratidzo zvinorambidza kumwe kufamba kwemotokari. Yero zviratidzo zvinoratidza kuti iwe unofanirwa kubata sevhisi munguva pfupi iri kutevera.

Nheyo yekushanda kweiyo emergency sensor

Iyi ndiyo inosungirwa sensor mhando kune dzese mota. Nechimiro, zviri nyore kwazvo uye zvine zvinhu zvinotevera:

- dzimba;

- membrane;

- vanofambidzana;

- pusher.

Iyo yekukurumidzira sensor uye mwenje wekuratidzira inosanganisirwa mune yakajairika magetsi wedunhu. Kana injini yadzimwa uye pasina kumanikidzwa, diaphragm iri panzvimbo yakatwasuka, macustomer wedunhu akavharwa, uye pusher yakadzorerwa zvizere. Parizvino injini painotangwa, magetsi anoiswa pane inonzwa zvemagetsi, uye mwenje uri padheshibhodhi unovhenekera kwechinguva kudzamara pari kudikanwa mafuta emafuta ekumisikidzwa mugadziriro.

Inoshanda pane iyo membrane, iyo inofambisa iyo pusher uye inovhura maseketi macontact. Kana kumanikidza kuri mukukwenenzvera sisitimu kuchidonha, diaphragm inotwasuka zvakare, uye dunhu rinovhara, kubatidza mwenje wechiedza.

Mashandiro emhedzisiro yekumanikidza anoshanda

Icho chigadzirwa cheanalogog icho chinoratidza iko kudzvinyirira kwazvino muchirongwa uchishandisa chiratidzo-chemhando chiratidzo. Nechimiro, yakajairika mehendi sensor yekutora kuverenga kwemafuta emafuta ine:

- dzimba;

- membranes (diaphragms);

- pusher;

- inotsvedza;

- Nichrome ichitenderera.

Mhedzisiro yekumanikidza anotumira anogona kuve rheostat kana kukurudzira. Muchiitiko chekutanga, chikamu chemagetsi chiri rheostat. Kana injini iri kumhanya, kumanikidza kunomuka mu lubrication system, iyo inoshanda pane iyo membrane uye, semhedzisiro, pusher inoshandura chinzvimbo cheiyo chinotsvedza chiri mundiro ine nichrome waya ichitenderera. Izvi zvinotungamira mukuchinja mukushora uye kufamba kweiyo analog chiratidzo tsono.

Pulse sensors yakashongedzerwa ne thermobimetallic plate, uye yavo inoshandura ine maviri ekutaurirana: iyo yekumusoro iplate ine mweya unosunganidzwa kune chiratidzo museve, uye wezasi. Iyo yekupedzisira iri kusangana neiyo sensor diaphragm uye inopfupiswa pasi (pasi kune mota mota). Iyo yazvino inoyerera kuburikidza neepamusoro uye ezasi maficha evashanduri, ichidziisa ndiro yayo yepamusoro uye ichimutsa shanduko mune chinzvimbo chemuseve. Iyo bimetallic ndiro mune iyo sensor zvakare inokanganisa uye inovhura iwo macontact kusvika itonhorere. Izvi zvinoona kuti dunhu rakavharwa zvachose uye rakavhurwa. Mhando dzakasiyana dzekumanikidza mu lubrication system ine mhedzisiro pane yekubatana kwepazasi uye chinja nguva yekuvhura yedunhu (ndiro inotonhora). Nekuda kweizvozvo, imwe kukosha kwazvino inopihwa kune yemagetsi control unit, uyezve kune iyo pointer chiratidzo, iyo inosarudza iyo yazvino yekumanikidza kuverenga.

Mafuta epanzvimbo sensor, kana epamhepo dipstick

Munguva pfupi yapfuura, vagadziri vemotokari vanowedzera vachisiya kushandisa dhipatimendi rekare rekutarisa huwandu hwemafuta enjini vachida maseru emagetsi.

Iyo senji yemafuta (dzimwe nguva inonziwo chidimbu chemagetsi) inozviongorora nhanho panguva yekushanda kwemotokari uye inotumira kuverenga kudashboard kune mutyairi. Kazhinji, inowanikwa pazasi peinjini, pane sump, kana padyo nefirita yemafuta.

Nechimiro, maseru maseru maseru akakamurwa kuita aya anotevera marudzi:

- Mechanical, kana kuyangarara. Inoitwa ichiyangarara akashongedzerwa pamwe zvachose magineti uye vertically akatarisa chubhu ine rutsanga chinja. Kana huwandu hwemafuta hwachinja, iyo ichiyangarara inofamba ichitevedza chubhu uye kana padanho padiki rasvika, switch yemutsanga inovhara dunhu uye inopa magetsi kune inoenderana mwenje wechiedza padhibhodhi.

- Thermal. Pamwoyo peichi chishandiso tambo inodziya-kupisa, kune iyo diki voltage inoiswa kuchidziisa. Mushure mekusvika pakumisikidzwa tembiricha, iyo voltage inodzimwa uye waya inotonhorera pasi kune tembiricha yemafuta. Zvichienderana nekuti inguvai inopfuura, huwandu hwemafuta muhurongwa hunotsanangurwa uye chiratidzo chinoenderana chinopihwa.

- Magetsi. Rudzi rwe sensor iyi subtype ye thermal. Dhizaini yayo inoshandisawo tambo inoshandura kusagadzikana zvinoenderana nekupisa kwekupisa. Kana tambo yakadaro yakanyudzwa muinjini yemafuta, kushomeka kwayo kunodzikira, izvo zvinoita kuti zvikwanise kuona huwandu hwemafuta muhurongwa nekukosha kwemagetsi anobuda. Kana huwandu hwemafuta hwadzikira, iyo sensor inotumira chiratidzo kuchikamu chekutonga, icho chinozvifananidza nedata pane tembiricha yemafuta uye inoratidza chiratidzo kuti ivhure.

- Ultrasonic. Iyo sosi yeiyo ultrasonic pulses inotungamirwa mupani yemafuta. Kufungidzira kubva pamusoro pemafuta, mapuri akadaro anodzoserwa kune anogamuchira. Iyo yekufambisa nguva yechiratidzo kubva panguva yekutumira kune yayo kudzoka inotarisa huwandu hwemafuta.

Mashandiro anoita tembiricha yemafuta

Iyo injini yemafuta tembiricha yekudzora sensor isarudzo yekusarudzika yeiyo lubrication system. Basa rayo guru ndere kuyera oiri yekupisa yemafuta uye kuendesa iyo inoenderana dhata kune dhibhodhi chiratidzo. Iyo yekupedzisira inogona kuve yemagetsi (yedhijitari) kana mehendi (chinja).

Pakasiyana tembiricha, mafuta anochinja ayo epanyama zvimiro, izvo zvinokanganisa mashandiro einjini uye kuverenga kwevamwe sensors. Semuenzaniso, mafuta anotonhora ane hushoma hushoma, hunofanirwa kutariswa pakuwana dhata remafuta. Kana injini yeinjini ikasvika pamatembiricha ari pamusoro pe130 ° C, inotanga kupisa, izvo zvinogona kukonzeresa kuderera kukuru kwehunhu hwayo.

Kusarudza uko injini yekushisa tembiricha iripo haina kuoma - kazhinji inoiswa zvakananga mujini crankcase. Mune mamwe mamodheru emota, inosanganiswa neiyo senji yemafuta. Iko kushanda kweiyo tembiricha sensor kunoenderana nekushandiswa kwenzvimbo dze semiconductor thermistor.

Kana ichipisa, kushomeka kwayo kunodzikira, izvo zvinoshandura ukuru hwemhepo inobuda, iyo inopihwa kune yemagetsi control unit. Kuongorora iyo yakagamuchirwa data, iyo ECU inoendesa ruzivo kune dashibhodhi zvinoenderana neyakaisetwa marongero (coefficients).

Zvimiro zveiyo yemhando yepamusoro sensor

Injini yemafuta yemhando sensor inokwanisawo. Nekudaro, sezvo zvakasvibisa zvakasiyana (zvinotonhorera, zvigadzirwa zvekupfeka, macarbon deposits, nezvimwewo) zvinopinda mumafuta panguva yekushanda kweinjini, hupenyu hwayo hwebasa hunodzikira, uye hazviwanzo kurongeka kutevedzera kurudziro yemugadziri yekutsiva nguva.

Nheyo yekushanda kweiyo sensor yekutarisa mhando yeinjini yemafuta inoenderana nekuyera dielectric inogara iri pakati, inoshanduka zvinoenderana nemakemikari akaumbwa. Ndokusaka yakamisikidzwa nenzira yekuti inyurwe zvishoma mumafuta. Kazhinji kazhinji, ino nharaunda inowanikwa pakati peiyo firita uye humburumbira.

Nechimiro, iyo sensor yemafuta emhando yekudzora i polymer substrate panoshandiswa matanda emhangura (maelektrode). Dzinotungamirwa vaviri-vaviri dzichitarisana, dzichiumba imwe sensor mune vaviri vaviri. Izvi zvinokutendera iwe kuti uwane iyo chaiyo yakajeka ruzivo. Hafu yemagetsi inonyudzwa mumafuta, iyo ine dielectric zvivakwa, ichiita kuti mahwendefa ashande kunge capacitor. Kune akatarisana nemagetsi, yazvino inogadzirwa inoyerera ichienda kune yekuwedzera. Iyo yekupedzisira, zvichibva pahukuru hwazvino, inopa imwe voltage kumota yeECU, uko kunoenzaniswa nereferensi kukosha. Zvichienderana nemhedzisiro yakawanikwa, mutungamiriri anogona kuburitsa meseji nezve yakaderera mafuta mhando kune iyo dashboard.

Kururamisa mashandiro e-lubrication system sensors uye kutarisa kwemamiriro emafuta kunovimbisa kushanda kwakakodzera uye kuwedzera kwehupenyu hweinjini, asi zvinonyanya kukosha - kuchengetedzeka uye kunyaradzwa kwekushanda kwemota. Kufanana nezvimwe zvikamu, zvinoda kugara zvichiongororwa zvehunyanzvi, kuongororwa kwekushandisika, uye kumisikidzwa kwakakodzera kana kukanganiswa kwaonekwa.