Mutu wamkati wamkati wamoto woyaka

Zamkatimu

- Cylinder mutu umagwira

- Kugawidwa kwa mitu yamphamvu

- Cylinder mutu gasket

- Chivundikiro chamutu wa Cylinder

- Makhalidwe apamwamba a injini yamphamvu ya injini ziwiri

- Makhalidwe apamwamba a injini yamphamvu yamphamvu yamagetsi anayi

- Chipinda choyaka moto

- Kulowera ndi kubwereketsa

- Malangizo a Valve

- Mavavu pamutu wamphamvu wa injini

- Mutu wamphamvu wama valve awiri

- Mutu wamagetsi atatu

- Valavu yamphamvu yamagetsi anayi

- Mutu wamphamvu wamiyala isanu

Mawu akuti "cylinder head" sanabwere mwangozi. Monga mutu wa munthu, zochita zovuta kwambiri komanso zofunika kwambiri za injini yoyaka mkati zimachitika pamutu wa silinda. Mutu wa silinda ndi gawo la injini yoyaka mkati, yomwe ili kumtunda kwake (kumtunda). Zimalumikizidwa ndi ma ducts a mpweya wa mathirakiti olowera ndi kutulutsa, ali ndi magawo a makina a valve, majekeseni ndi ma spark plugs kapena mapulagi owala. Mutu wa silinda umakwirira pamwamba pa silinda. Mutu ukhoza kukhala umodzi wa injini yonse, payokha pa silinda iliyonse kapena padera pamzere wosiyana wa masilinda (injini yooneka ngati V). Amangiriridwa pa cylinder block ndi zomangira kapena mabawuti.

Mawu akuti "cylinder head" sanabwere mwangozi. Monga mutu wa munthu, zochita zovuta kwambiri komanso zofunika kwambiri za injini yoyaka mkati zimachitika pamutu wa silinda. Mutu wa silinda ndi gawo la injini yoyaka mkati, yomwe ili kumtunda kwake (kumtunda). Zimalumikizidwa ndi ma ducts a mpweya wa mathirakiti olowera ndi kutulutsa, ali ndi magawo a makina a valve, majekeseni ndi ma spark plugs kapena mapulagi owala. Mutu wa silinda umakwirira pamwamba pa silinda. Mutu ukhoza kukhala umodzi wa injini yonse, payokha pa silinda iliyonse kapena padera pamzere wosiyana wa masilinda (injini yooneka ngati V). Amangiriridwa pa cylinder block ndi zomangira kapena mabawuti.

Cylinder mutu umagwira

- Zimapanga danga la kuyaka - limapanga malo oponderezedwa kapena gawo lake.

- Amapereka malo osungira (4-stroke engine).

- Amapereka kutentha kwa chipinda choyaka moto, mapulagi ndi mavavu.

- Kutseka chipinda choyaka mpweya wolimba komanso chopanda madzi.

- Amapereka kusungidwa kwa pulagi kapena injector.

- Imagwira ndikuwongolera kuthamanga kwa kuyaka - voteji yayikulu.

Kugawidwa kwa mitu yamphamvu

- Cylinder amatsogolera injini yama stroke-stroke ndi zinayi.

- Cylinder amatsogolera poyatsira komanso kuyatsa kwamagetsi.

- Mitu utakhazikika mpweya kapena madzi.

- Magawo olekanitsidwa ndi silinda limodzi, mutu wa intaneti kapena V-injini.

- Cylinder mutu ndi nthawi ya valavu.

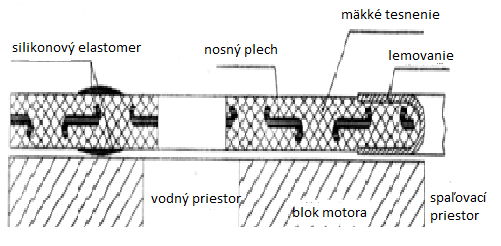

Cylinder mutu gasket

Pali chisindikizo pakati pamutu wamiyendo wamiyendo yamiyala, yomwe imasindikiza chipinda choyaka moto mosavomerezeka ndipo imalepheretsa mafuta ndi chozizira kuthawa (kusakanikirana). Timagawa zisindikizo muzitsulo zomwe zimatchedwa chitsulo komanso kuphatikiza.

Zitsulo, mwachitsanzo zisindikizo zamkuwa kapena zotayidwa, zimagwiritsidwa ntchito mu injini zazing'ono, zothamanga kwambiri, zoziziritsa mpweya (ma scooter, njinga zamoto ziwiri mpaka 250 cc). Ma injini atakhazikika pamadzi amagwiritsa ntchito chidindo chomwe chimakhala ndi ulusi wokhala ndi graphite wokhala ndi zomata zapulasitiki zothandizidwa ndi chitsulo.

Chivundikiro chamutu wa Cylinder

Gawo lofunika kwambiri pamutu wamiyala ndichotchinga chomwe chimaphimba sitima yamagetsi ndikuletsa mafuta kuti asatayike mu injini.

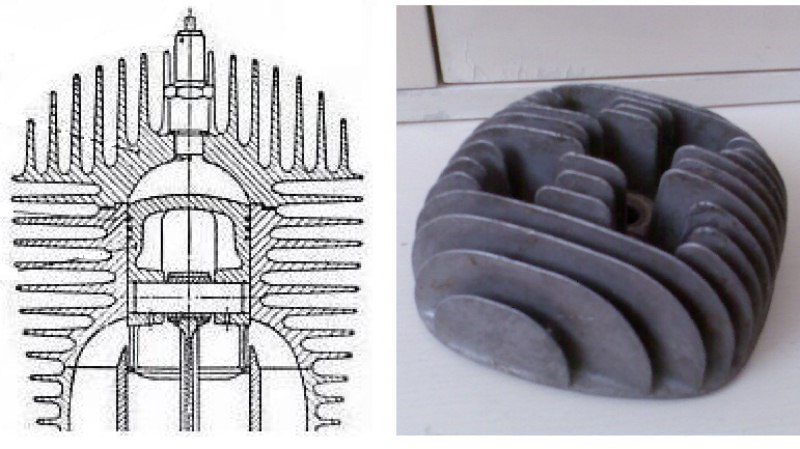

Makhalidwe apamwamba a injini yamphamvu ya injini ziwiri

Mutu wamphamvu wamakina opopera awiri nthawi zambiri umakhala wosavuta, utakhazikika mpweya (wopota pamwamba) kapena wamadzi. Chipinda choyaka moto chimatha kukhala chosakanikirana, biconvex kapena chozungulira, nthawi zambiri chokhala ndi malo odana ndi kugogoda. Chingwe cha pulagi chakumaso chili pamizere yamphamvu. Zitha kupangidwa kuchokera ku chitsulo chosapanga dzimbiri (zojambula zakale za injini) kapena aloyi ya aluminium (yomwe ikugwiritsidwa ntchito pano). Kulumikizana kwa mutu wa injini ya sitiroko iwiri pamiyala yamphamvu kumatha kumangidwa, kulumikizidwa, kuphatikizika ndi zomangira zolimbitsa, kapena mutu umodzi.

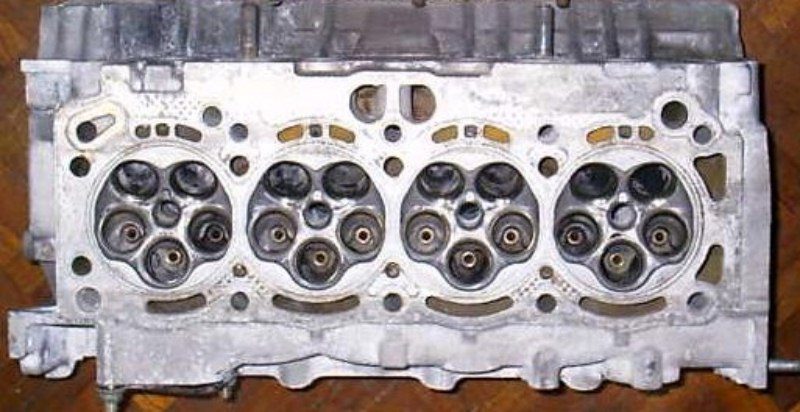

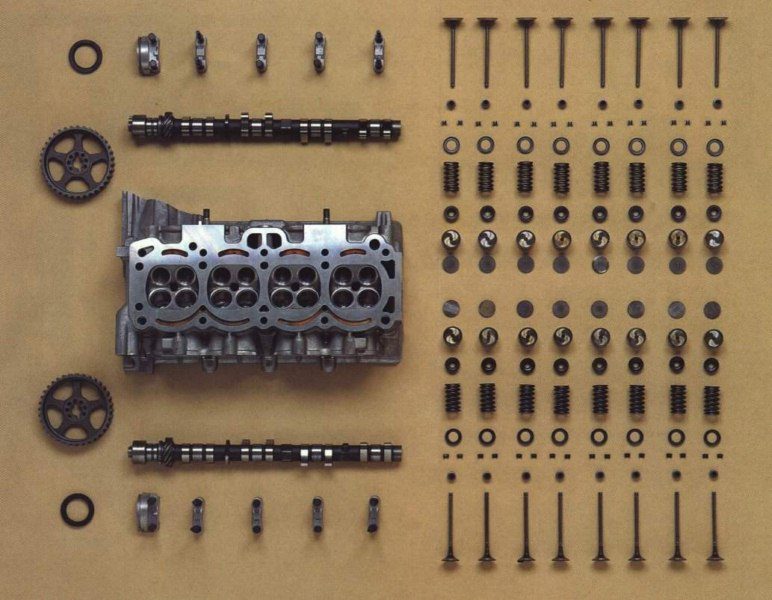

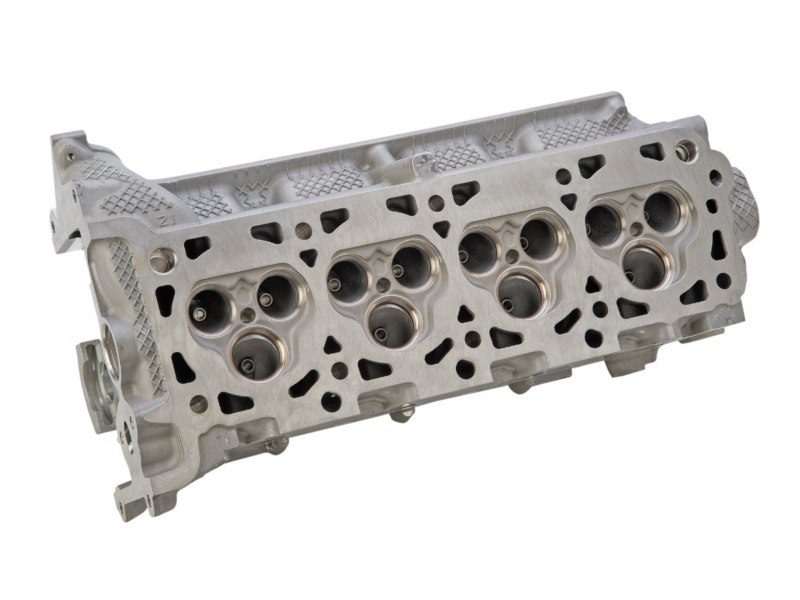

Makhalidwe apamwamba a injini yamphamvu yamphamvu yamagetsi anayi

Mapangidwe a mutu wa injini za sitiroko zinayi ayeneranso kupereka kusintha kwa masilindala a injini. Lili ndi njira zolowera ndi zotulutsira, mbali za njira yogawa gasi yomwe imayendetsa ma valve, ma valve okha, pamodzi ndi mipando yawo ndi maupangiri, ulusi wokonzera spark plug ndi nozzles, njira zoyendetsera mafuta ndi kuziziritsa media. Ilinso gawo la chipinda choyaka moto. Chifukwa chake, ndizovuta kwambiri pamapangidwe ndi mawonekedwe ake poyerekeza ndi mutu wa silinda wa injini yamitundu iwiri. Mutu wa silinda wa injini yamagetsi anayi amapangidwa kuchokera ku chitsulo chonyezimira, kapena chitsulo chosungunuka, kapena chitsulo chonyezimira - chomwe chimatchedwa zitsulo zotayidwa kapena zitsulo zotayidwa pa injini zoziziritsa kukhosi. Ma injini okhala ndi mpweya amagwiritsa ntchito zitsulo zotayidwa kapena zitsulo zotayidwa. Chitsulo chachitsulo sichimagwiritsidwa ntchito ngati mutu ndipo chasinthidwa ndi aloyi ya aluminiyamu. Mbali yofunika kwambiri pakupanga zitsulo zopepuka sizomwe zimakhala zolemera kwambiri ngati matenthedwe abwino kwambiri. Popeza kuti kuyaka kumachitika pamutu wa silinda, zomwe zimapangitsa kutentha kwakukulu mu gawo ili la injini, kutentha kumayenera kusamutsidwa ku choziziritsa msanga. Ndiyeno aluminium alloy ndi chinthu choyenera kwambiri.

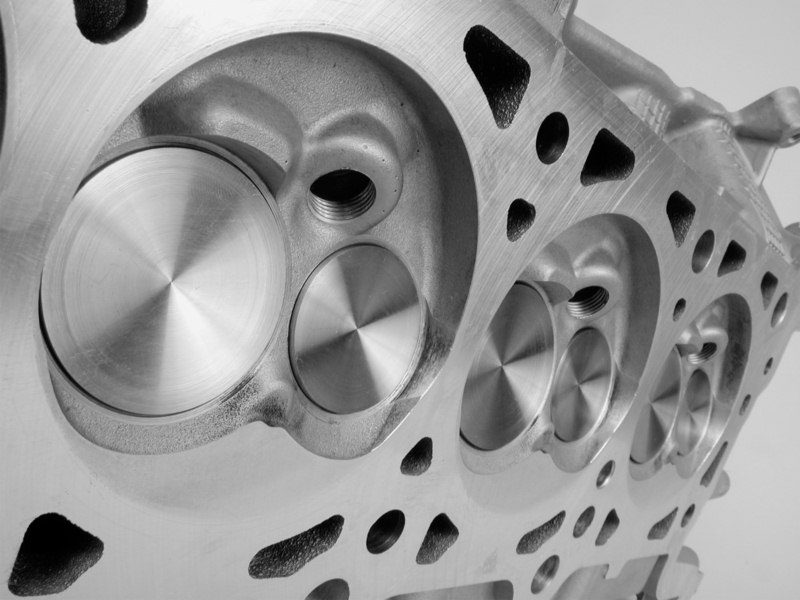

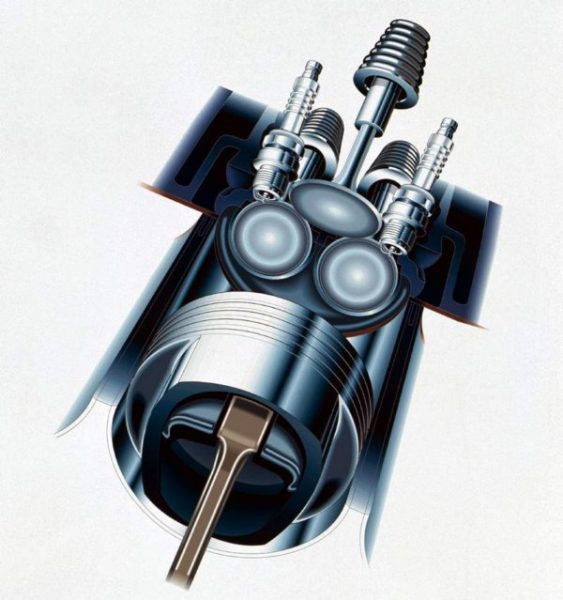

Chipinda choyaka moto

Chipinda choyaka moto ndichinthu chofunikira kwambiri pamutu wamphamvu. Iyenera kukhala ya mawonekedwe olondola. Zofunikira zazikulu m'chipinda choyaka moto ndi izi:

- Kuchita bwino komwe kumachepetsa kutentha.

- Lolani kugwiritsa ntchito ma valavu ochulukirapo kapena kukula kokwanira kwa ma valve.

- Kutsegula kwathunthu kwa kudzazidwa kwamphamvu.

- Ikani kandulo pamalo olemera kwambiri kumapeto kwa kufinya.

- Kupewa kuphulika kwa ziphuphu.

- Kupondereza malo opatsirana.

Izi ndizofunikira kwambiri chifukwa chipinda choyaka moto chimakhudza mapangidwe a ma hydrocarbon, amatenga kuyaka, mafuta, phokoso loyaka moto komanso makokedwe. Chipinda choyaka moto chimatsimikiziranso kuchuluka kwakanthawi kokwanira ndipo kumakhudza kutentha.

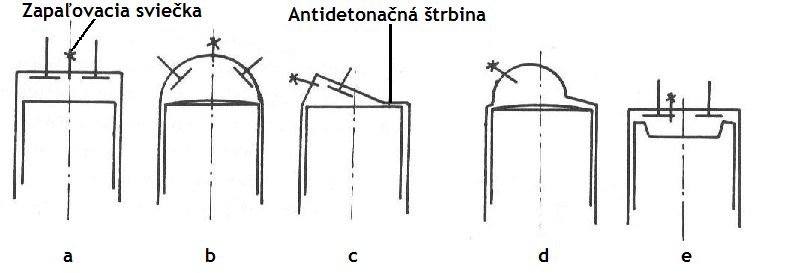

Makina oyaka chipinda

a - bafa, b - hemispherical, c - mphesa, d - Asymmetric hemispherical, e - Herons mu pisitoni

Kulowera ndi kubwereketsa

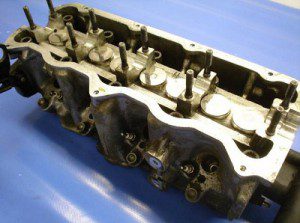

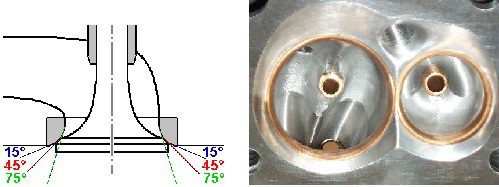

Madoko olowera ndi olowera amatha ndi mpando wa valavu molunjika pamutu wamphamvu kapena wokhala ndi mpando wolowetsedwa. Mpando wolunjika wa valavu umapangidwa mwachindunji m'mutu kapena amatha kutchedwa. chishalo chamkati chopangidwa ndi zida zapamwamba kwambiri za aloyi. Malo olumikiziranawo ali pansi kukula kwake. Mbali ya bevel ya mpando wa valavu nthawi zambiri imakhala 45 °, chifukwa mtengowu umakwaniritsa kukhathamira kwabwino pamene valavu yatsekedwa ndipo mpando umadziyeretsa wokha. Mavavu oyamwa nthawi zina amapendekera pa 30 ° kuti aziyenda bwino pamalo okhala.

Malangizo a Valve

Ma valve amayenda motsatira ma valve. Maupangiri a valavu amatha kupangidwa kuchokera ku chitsulo chosungunuka, aluminiyamu-bronze alloy, kapena kupangidwa mwachindunji pamutu wamutu wamphamvu.

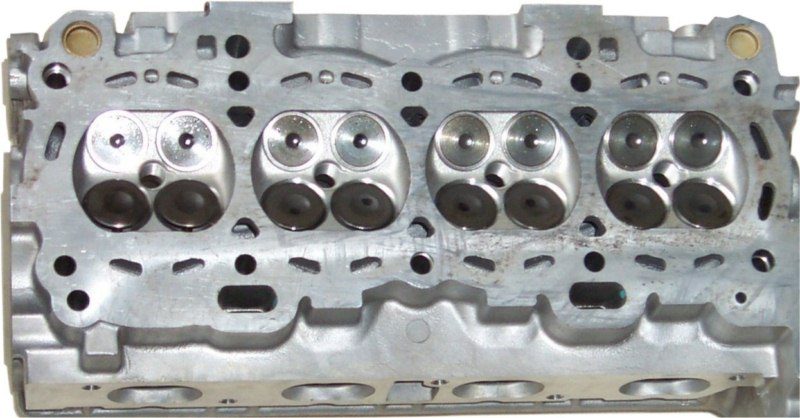

Mavavu pamutu wamphamvu wa injini

Amayenda mowongolera, ndipo mavavu okha amakhala pampando. Valavu ngati gawo la valavu yowongolera yoyatsira makina oyaka amkati imapanikizika ndimakina komanso matenthedwe pantchito. Kuchokera pamawonekedwe amakanema, koposa zonse ndizodzaza ndi kuthamanga kwa mpweya wakupsyinjika mchipinda choyaka moto, komanso mphamvu yoyendetsedwa kuchokera ku cam (jack), mphamvu yosagwira ntchito pakubwezeretsanso, komanso mikangano yamakina. ndekha. Kupsinjika kwamphamvu ndikofunikanso, chifukwa valavu imakhudzidwa makamaka ndi kutentha m'chipinda choyaka moto komanso kutentha kozungulira ma mpweya otentha otulutsa (mavavu otulutsa). Ndi mavavu otulutsa utsi, makamaka mu injini zamagetsi, zomwe zimawonetsedwa ndi matenthedwe otentha, ndipo kutentha kwakomweko kumatha kufikira 900 ° C. Kutentha kumatha kusamutsidwa pampando ndi valavu itatsekedwa ndi tsinde la valavu. Kutentha kuchokera kumutu kupita ku tsinde kumatha kukulitsidwa ndikudzaza patsekeke mkati mwa valavu ndi zinthu zoyenera. Nthawi zambiri, amagwiritsa ntchito mpweya wa sodium, womwe umadzaza tsinde theka lokha, kotero kuti valavu ikamayenda, mkati mwake mumadzaza madzi. Tsinde mu ma injini ang'onoang'ono (okwera) amapangidwa poboola dzenje; pankhani ya injini zazikulu, gawo lina la mutu wa valavu amathanso kukhala lopanda pake. Chitsulo cha valve nthawi zambiri chimakhala chrome. Chifukwa chake, kutentha kwakatundu sikofanana mavavu osiyanasiyana, zimadaliranso ndi kuyaka komweko ndikupangitsa kupsinjika kwamagetsi mu valavu.

Mitu ya valve yolowera nthawi zambiri imakhala yayikulu m'mimba mwake kuposa mavavu otulutsa mpweya. Ndi nambala yosamvetseka ya mavavu (3, 5), pali ma valve ambiri olowera pa silinda kuposa ma valve otulutsa mpweya. Izi ndi chifukwa cha kufunikira kuti mukwaniritse zomwe zingatheke - mphamvu yeniyeni yeniyeni, choncho, kudzazidwa kwabwino kwa silinda ndi chisakanizo choyaka chamafuta ndi mpweya.

Kupanga mavavu oyamwa, ma steels okhala ndi pearlite, opangidwa ndi silicon, nickel, tungsten, ndi ena amagwiritsidwa ntchito makamaka. Nthawi zina amagwiritsa ntchito aloyi titaniyamu. Mavavu utsi poyera matenthedwe amapangidwa kuchokera mkulu alloy (chromium-faifi tambala) steels ndi dongosolo austenitic. Chida cholimba chachitsulo kapena chinthu china chapadera chimalumikizidwa pampando. stellite (alloy malayable cobalt yokhala ndi chromium, kaboni, tungsten kapena zinthu zina).

Mutu wamphamvu wama valve awiri

Mutu wamagetsi atatu

Valavu yamphamvu yamagetsi anayi

Mutu wamphamvu wamiyala isanu