Njira yogawa gasi - gulu la valve

Zamkatimu

Cholinga ndi mitundu ya nthawi:

1.1. Cholinga cha njira yogawa gasi:

Cholinga cha makina a nthawi ya valve ndikudutsa mafuta atsopano osakaniza mu masilinda a injini ndikutulutsa mpweya wotulutsa mpweya. Kusinthana kwa gasi kumachitika kudzera m'malo olowera ndi kutulutsa, omwe amatsekedwa mwamphamvu ndi zinthu za lamba wanthawi motsatira njira yovomerezeka ya injini.

1.2. Ntchito yama Valve:

Cholinga cha gulu la vavu ndikutseka madoko olowera ndi kutulutsa ndikutsegula pa nthawi yoikidwiratu yanthawi yomwe yatchulidwa.

1.3. Mitundu ya nthawi:

kutengera ziwalo zomwe ma injini amagetsi amalumikizana ndi chilengedwe, lamba wa nthawi ndi valavu, spool komanso kuphatikiza.

1.4. Kuyerekeza mitundu ya nthawi:

nthawi ya valve ndiyofala kwambiri chifukwa chakapangidwe kake kosavuta komanso ntchito yodalirika. Kusindikiza koyenera komanso kodalirika kwa malo ogwirira ntchito, omwe amakwaniritsidwa chifukwa chakuti ma valve amakhala osasunthika pakathamangidwe kazitsulo, amapereka mwayi waukulu kuposa valavu kapena nthawi yophatikizira. Chifukwa chake, nthawi yama valve imagwiritsidwa ntchito kwambiri.

Valve gulu gulu:

2.1. Valavu chipangizo:

Mavavu amagetsi amakhala ndi tsinde ndi mutu. Mitu nthawi zambiri imakhala yopindika, yotsekemera kapena yopangidwa ndi belu. Mutu uli ndi lamba wocheperako (pafupifupi 2 mm) ndi bevel yosindikiza ya 45˚ kapena 30˚. Lamba wama cylindrical amalola, kumbali imodzi, kuti asunge gawo lalikulu la valavu popera chosindikiza chamfer, komano, kuwonjezera kuuma kwa valavu ndikuteteza kupindika. Zowonjezeka kwambiri ndi ma valve okhala ndi mutu wolimba komanso chidindo chosindikiza pamakona a 45˚ (awa nthawi zambiri amakhala mavavu olowetsa), ndikuwonjezera kudzaza ndi kuyeretsa masilindala, valavu yolowera imakhala ndi gawo lalikulu kuposa valavu yotulutsa. Mavavu otulutsa nthawi zambiri amapangidwa ndi mutu wa mpira.

Izi zimathandizira kutuluka kwa mpweya wotulutsa mpweya kuchokera kumasilinda, komanso kumawonjezera mphamvu ndi kukhazikika kwa valve. Kuwongolera momwe kutentha kumachotsedwa pamutu wa valavu ndikuwonjezera kusasinthika konse kwa valavu, kusintha pakati pa mutu ndi tsinde kumapangidwa pamakona a 10˚ - 30˚ komanso ndi ma radius akulu opindika. Pamwamba pa tsinde la valve, ma grooves amapangidwa ndi mawonekedwe a conical, cylindrical kapena apadera, malingana ndi njira yovomerezeka yolumikizira kasupe ku valve. Kuziziritsa kwa sodium kumagwiritsidwa ntchito m'mainjini angapo kuti muchepetse kupsinjika kwamafuta pama valve ophulika. Kuti muchite izi, valavuyo imapangidwa ngati dzenje, ndipo chifukwa chake ndi theka lodzaza ndi sodium, yomwe imasungunuka ndi 100 ° C. Injini ikamathamanga, sodium imasungunuka ndikuyenda kudzera muzitsulo za valve, kusuntha kutentha kuchokera kumutu wotentha kupita ku tsinde lozizirira ndipo kuchokera pamenepo kupita ku valavu actuator.

2.2. Kulumikiza valavu kumapeto kwake:

mapangidwe a chipangizochi ndiosiyanasiyana kwambiri, koma kapangidwe kofala kwambiri ndi theka-ma cones. Mothandizidwa ndi ma cones awiri, omwe amalowa mumayendedwe opangidwa ndi tsinde la valavu, mbaleyo imakanikizidwa, yomwe imagwira kasupe ndipo salola kuti disassembling ya unit. Izi zimapanga kulumikizana pakati pa kasupe ndi valavu.

2.3. Malo ampando wama Valve:

Mu injini zonse zamakono, mipando yotulutsa utsi imapangidwa mosiyana ndi mutu wamphamvu. Mipando yotere imagwiritsidwanso ntchito pokoka makapu pamene mutu wamphamvu umapangidwa ndi aloyi ya aluminiyamu. Ikaponyedwa chitsulo, zisoti zimapangidwamo. Kapangidwe, mpandowo ndi mphete yomwe imamangiriridwa pamutu wamphamvu pampando wopangidwa mwaluso. Nthawi yomweyo, ma grooves nthawi zina amapangidwira kumtunda kwa mpando, womwe, mukapanikizidwa pampando, umadzazidwa ndi mutu wamiyala yamphamvu, potero amaonetsetsa kuti akumangiririka. Kuphatikiza pakupanikizika, kulumikiza kumatha kuchitidwanso pomangirira chishalo. Kuonetsetsa kuti malo ogwirira ntchito akukhazikika pamene valavu yatsekedwa, malo ogwiritsira ntchito mpandowo amayenera kupangika chimodzimodzi ndi kusindikiza chamfer kwa mutu wa valavu. Pachifukwa ichi, zishalo zimapangidwa ndi zida zapadera zokongoletsa osakhala 15 osati, 45˚ ndi 75˚ kuti mupeze tepi yosindikiza pakona ya 45˚ ndi mulifupi wa 2 mm. Makona ena onse amapangidwa kuti athandize kuyenda mozungulira chishalo.

2.4. Malo Otsogolera Valve:

kapangidwe ka maupangiriwo ndiosiyanasiyana. Nthawi zambiri, amagwiritsa ntchito maulalo osalala akunja, omwe amapangidwa pamakina azipangizo opanda zingwe. Malangizo okhala ndi zingwe zakunja ndizosavuta kulumikiza koma ndizovuta kupanga. Pachifukwa ichi, ndikofunikira kwambiri kupanga njira yamphete yoyimira m'malo mwa lamba. Maupangiri amagetsi otulutsa utsi nthawi zambiri amagwiritsidwa ntchito kuwateteza ku zotsatira za makutidwe ndi okosijeni a mtsinje wotentha wa mpweya. Poterepa, maupangiri ataliatali amapangidwa, enawo omwe amapezeka mumayendedwe amutu wamutu wamphamvu. Pamene mtunda pakati pa kalozera ndi mutu wa valavu umachepa, dzenje lakutsogolo kwa mutu wa valavu limachepa kapena kufutukuka m'chigawo cha mutu wa valavu.

2.5. Springs chipangizo:

mu injini zamakono, akasupe odziwika bwino kwambiri okhala ndi phula lokhazikika. Kuti apange malo othandizira, malekezero amtundu wa kasupe amasonkhanitsidwa motsutsana wina ndi mzake ndikumamatira ndi mphumi zawo, chifukwa chake kuchuluka kwa ma coil kumakhala kawiri kapena katatu kuposa kuchuluka kwa akasupe ogwira ntchito. Mapeto omaliza amathandizidwa mbali imodzi ya mbaleyo ndi mbali ina ya mutu wamphamvu kapena chipika. Ngati pali chiopsezo cha kumvekera, akasupe a ma valve amapangidwa ndi phula losinthasintha. Bokosi lamagiya lopindidwa limakhotera kuchokera kumapeto ena a kasupe kupita kumapeto ena, kapena kuchokera pakati mpaka kumapeto onse awiri. Valavu ikatsegulidwa, ma windings oyandikira wina ndi mnzake amakhudza, chifukwa chake kuchuluka kwa magwiridwe antchito kumachepa, komanso kuchuluka kwa kusuntha kwaulere kwa masika kumawonjezeka. Izi zimachotsa mikhalidwe yamayimbidwe. Pachifukwa chomwechi, nthawi zina amagwiritsa ntchito akasupe oyenda mozungulira, omwe masanjidwe achilengedwe amasiyanasiyana malinga ndi kutalika kwawo ndikukhala kosamveka.

2.6. Zipangizo zopangira zida zamagulu zamagetsi:

• Mavavu - Ma valve akuyamwitsa akupezeka mu chrome (40x), chromium nickel (40XN) ndi zitsulo zina za alloy. Mavavu otulutsa mpweya amapangidwa ndi zitsulo zosagwira kutentha zomwe zimakhala ndi chromium, faifi tambala ndi zitsulo zina zophatikizira: 4Kh9S2, 4Kh10S2M, Kh12N7S, 40SH10MA.

• Mipando ya valavu - Zitsulo zosagwirizana ndi kutentha kwapamwamba, zitsulo zotayidwa, mkuwa wa aluminiyamu kapena cermet zimagwiritsidwa ntchito.

• Maupangiri a ma valve ndi malo ovuta kupanga ndipo amafunikira kugwiritsa ntchito zinthu zokhala ndi kutentha kwambiri komanso kusamva bwino komanso kuwongolera bwino kwamafuta, monga chitsulo chotuwa cha pearlitic ndi mkuwa wa aluminiyamu.

• Akasupe - opangidwa ndi waya wokhotakhota kuchokera ku stoma yamasika, mwachitsanzo 65G, 60C2A, 50HFA.

Ntchito yamagetsi yamagetsi:

3.1. Njira yolumikizirana:

njira yolumikizirana ndiyolumikizana kwambiri ndi crankshaft, yoyenda molumikizana nayo. Lamba wanyengo amatsegula ndikusindikiza madoko olowera ndi kubwerekera a masilindala amodzi m'njira wamba. Iyi ndi njira yosinthira mpweya wamagalasi.

3.2 Ntchito yoyendetsa nthawi:

Kuyendetsa nthawi kumadalira komwe kuli camshaft.

• Ndi shaft yapansi - kupyolera muzitsulo zopangira ntchito zowonongeka zimapangidwa ndi mano otsatiridwa, ndi ntchito mwakachetechete, mphete ya gear imapangidwa ndi textolite. Chida cha parasitic kapena unyolo chimagwiritsidwa ntchito poyendetsa mtunda wautali.

• Ndi shaft pamwamba - wodzigudubuza unyolo. Phokoso laling'ono, kapangidwe kosavuta, kulemera kochepa, koma dera limatha ndikutalika. Kudzera pa lamba wanthawi ya neoprene wolimbikitsidwa ndi waya wachitsulo komanso wokutidwa ndi wosanjikiza wa nayiloni wosamva kuvala. Kupanga kosavuta, ntchito yachete.

3.3. Ndondomeko yogawa gasi:

Malo okwanira otsegulira mpweya kudzera mu valavu zimatengera nthawi yotsegulira. Monga mukudziwa, mu injini zinayi zamagetsi, kuti mugwiritse ntchito zikwapu zolowetsa komanso zotulutsa utsi, pisitoni imodzi imaperekedwa, yofanana ndi kuzungulira kwa crankshaft pofika 180˚. Komabe, zokumana nazo zawonetsa kuti pakudzaza bwino ndi kuyeretsa silinda ndikofunikira kuti nthawi yodzaza ndikutsitsa ikhale yayitali kuposa zikwapu za pistoni, i.e. kutsegulidwa ndi kutsekedwa kwa ma valve sikuyenera kuchitika pamapeto a sitiroko ya piston, koma ndi zina zomwe zimachedwa kapena kuchedwa.

Nthawi zotsegulira ndi kutsekera ma valve zimawonetsedwa m'makona ozungulira a crankshaft ndipo amatchedwa nthawi ya valve. Kuti zikhale zodalirika kwambiri, magawo awa amapangidwa ngati ma chart a pie (mkuyu 1).

Vavu yoyamwa nthawi zambiri imatsegulidwa ndi ngodya yopitilira φ1 = 5˚ - 30˚ pisitoni isanafike pakati pakufa. Izi zimatsimikizira gawo lina la valve kumayambiriro kwenikweni kwa sitiroko yodzaza ndipo motero kumapangitsa kudzazidwa kwa silinda. Vavu yoyamwa imatsekedwa ndi ngodya yochedwa φ2 = 30˚ - 90˚ pisitoni ikadutsa pakati pakufa. Kuchedwa kwa kutseka kwa valve kumapangitsa kuti mafuta azitha kugwiritsidwa ntchito kuti apititse patsogolo mafuta ndikuwonjezera mphamvu ya injini.

Valavu yotulutsa mpweya imatsegulidwa ndi ngodya yodutsa φ3 = 40˚ - 80˚, i.e. kumapeto kwa sitiroko, pamene kupanikizika kwa mpweya wa silinda kumakhala kwakukulu (0,4 - 0,5 MPa). Kwambiri ejection wa yamphamvu mpweya, anayamba pa kuthamanga, kumabweretsa kutsika mofulumira kuthamanga ndi kutentha, amene amachepetsa kwambiri ntchito kusamutsidwa ntchito mpweya. Vavu yotulutsa mpweya imatseka ndi ngodya yochedwa φ4 = 5˚ - 45˚. Kuchedwa kumeneku kumapereka kuyeretsa bwino kwa chipinda choyaka moto kuchokera ku mpweya wotuluka.

Diagnostics, kukonza, kukonza:

4.1. Kuzindikira

Zizindikiro zodziwitsa:

- •Mphamvu yochepetsedwa ya injini yoyaka mkati:

- Kuchepetsa chilolezo;

- Ma valve osakwanira;

- Mavavu anagwira.

• Kuchuluka kwa mafuta: - Kuchepetsa chilolezo pakati pamagetsi ndi okwera;

- Ma valve osakwanira;

- Mavavu anagwira.

• Valani mu injini zoyaka mkati: - Kuvala kwa camshaft;

- kutsegula makamera a camshaft;

- Kuchulukitsa pakati pa zimayambira za valavu ndi ma bushings a valavu;

- Chilolezo chachikulu pakati mavavu ndi lifters;

- kusweka, kuphwanya kukhathamira kwa akasupe a valavu.

• Chizindikiro chotsika: - Mipando yama valve ndiyofewa;

- Kasupe wofewa kapena wosweka;

- Wotuluka vavu;

- Chotentha kapena chong'ambika mutu wamtengo wapatali

- Kusasintha kosasintha kwa matenthedwe.

• Chizindikiro cha kuthamanga. - Kutsika kwa mutu;

Njira zowunikira nthawi:

• Kuyeza kwa kupanikizika kwa silinda kumapeto kwa kupsinjika. Pakati pa muyeso, zinthu zotsatirazi ziyenera kukwaniritsidwa: injini yoyaka iyenera kutenthedwa ndi kutentha; Ma plugs akuyenera kuchotsedwa; Chingwe chapakati cha koyilo chodulira chimayenera kuthiridwa mafuta ndipo valavu ya throttle ndi valavu yampweya imatseguka. Kuyeza kumachitika pogwiritsa ntchito compressors. Kusiyanitsa kwamphamvu pakati pa zonenepa payokha sikuyenera kupitirira 5%.

4.2. Kusintha chilolezo matenthedwe mu nthawi lamba:

Kuyang'ana ndikusintha kusiyana kwa matenthedwe kumachitika pogwiritsa ntchito mbale zamagetsi motsatana mogwirizana ndi kayendetsedwe ka injini, kuyambira pa silinda yoyamba. Gawolo limasinthidwa bwino ngati makulidwe a makulidwe, ogwirizana ndi kusiyana kwabwino, amadutsa momasuka. Mukamasintha chilolezo, gwirani chopukutira chosinthira, kumasula mtedza wa kupanikizana, ikani mbale yololeza pakati pa tsinde la valavu ndi cholumikizira, ndikutembenuza chopukutira kuti chikonzere chilolezo chofunikira. Kenako mtedza wotsekerawo umamangika.

4.3. Kukonza gulu la ma Valve:

• Kukonza ma valve - zolakwa zazikulu ndizovala ndi kuwotcha kwa conical ntchito pamwamba, kuvala kwa tsinde ndi maonekedwe a ming'alu. Ngati mitu ikuwotcha kapena ming'alu ikuwoneka, ma valve amatayidwa. Ma valve opindika amawongoledwa pa makina osindikizira pamanja pogwiritsa ntchito chida. Zitsanzo za ma valve owonongeka zimakonzedwa ndi kusinthasintha kapena kusita kenako ndikuziyika mpaka kukula kwadzina kapena kukonzanso kwakukulu. Malo ogwirira ntchito owonongeka a mutu wa valve ndi pansi mpaka kukula kokonza. Mavavu amangiriridwa pamipando ndi ma abrasive pastes. Kulondola kwakupera kumafufuzidwa ndikutsanulira palafini pazitsulo zomangika, ngati sizikutha, ndiye kuti kugaya ndikwabwino kwa mphindi 4-5. Akasupe a valve samabwezeretsedwa, koma amasinthidwa ndi atsopano.

Mafunso ndi Mayankho:

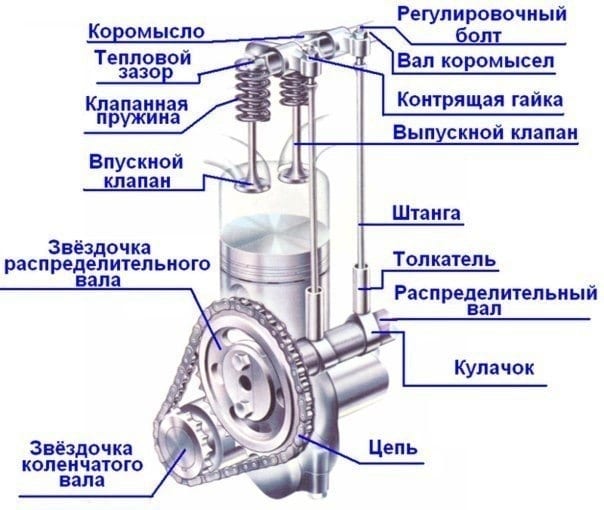

Ndi chiyani chomwe chikuphatikizidwa mu makina ogawa gasi? Ili pamutu wa silinda. Mapangidwe ake akuphatikizapo: bedi la camshaft, camshaft, ma valves, rocker arms, pushers, hydraulic lifters ndipo, mwa zitsanzo zina, chosinthira gawo.

ДKodi nthawi ya injini ndi chiyani? Njirayi imatsimikizira kupezeka kwanthawi yake kwa gawo latsopano la kusakaniza kwamafuta a mpweya ndi kuchotsedwa kwa mpweya wotulutsa mpweya. Kutengera kusinthidwa, imatha kusintha nthawi yanthawi ya valve.

Kodi njira yogawa gasi ili kuti? Mu injini yamakono yoyaka mkati, njira yogawa gasi imakhala pamwamba pa silinda mumutu wa silinda.