Usoro nkesa gas - otu valve

Ihe

Nzube na ụdị oge:

1.1. Nzube nke usoro nkesa gas:

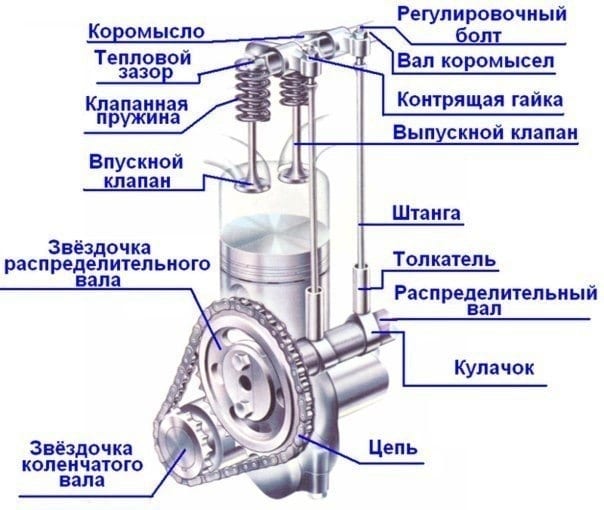

Ebumnuche nke usoro oge valvụ bụ ịfefe ngwakọta mmanụ ọhụrụ n'ime igwe cylinders ma hapụ gas na-ekpochapụ. A na-eme mgbanwe gas site na oghere ntinye na oghere, nke a na-emechi ya site na ihe ndị na-eme oge belt dị ka usoro ọrụ engine anabatara.

1.2. Ọrụ ọrụ Valve:

Ebumnuche nke otu valvụ bụ imechi ọnụ ụzọ mbata na ọdụ ụgbọ mmiri wee mepee ha n'oge a kapịrị ọnụ maka oge a kapịrị ọnụ.

1.3. Typesdị oge:

dabere na akụkụ nke ejiri ejiri cylinders jikọọ na gburugburu ebe obibi, oge bụ valvụ, spool na jikọtara.

1.4. Tụnyere ụdị oge:

oge nke valvụ bụ ihe kachasịkarị n'ihi nhazi ya dị mfe ma rụọ ọrụ a pụrụ ịdabere na ya. Odi ezigbo ihe kwesiri ntukwasi obi nke oghere oru a, enweta ya n'ihi eziokwu bu na valves na-anoro ugbua na nsogbu di elu na cylinders, na-enye nnukwu uru karie valvụ ma ọ bụ oge ejikọtara. Ya mere, a na-eji oge valve eme ihe.

Ngwa valvụ:

2.1. Ngwaọrụ valvụ:

Injin engine nwere okporo osisi na isi. A na-emekarị isi ndị dị larịị, kọnks ma ọ bụ nke mgbịrịgba. Isi nwere obere eriri cylindrical (ihe dị ka 2 mm) na bevel akara 45˚ ma ọ bụ 30˚. Oghere cylindrical na-enye ohere, n'otu aka, iji jigide isi dayameta nke valvụ ahụ mgbe ọ na-egweri bevel akara, na n'aka nke ọzọ, ịbawanye valvụ valị ma si otú a gbochie nrụrụ. Ihe kacha gbasaa bụ valves nwere isi dị larịị na bevel akara na nkuku nke 45˚ (ndị a na-abụkarị valvụ oriri), na iji meziwanye njuju na nhicha nke cylinders, valvụ oriri nwere nnukwu dayameta karịa valvụ ọkụ. A na-ejikarị bọlbụ isi na-emefucha valvụ.

Nke a na-eme ka ọpụpụ nke gas na-ekpochapụ si na cylinders dịkwuo mma, ma na-abawanye ike na ike nke valvụ ahụ. Iji meziwanye ọnọdụ maka iwepụ okpomọkụ site na isi valvụ ma mee ka valvụ ahụ na-adịghị agbanwe agbanwe, a na-eme mgbanwe n'etiti isi na azuokokoosisi na akụkụ nke 10˚ - 30˚ na nnukwu radius nke curvature. Na njedebe elu nke valvụ ahụ, a na-eme oghere nke conical, cylindrical ma ọ bụ ọdịdị pụrụ iche, dabere na usoro a nabatara nke itinye mmiri na valvụ ahụ. A na-eji ntụ oyi sodium mee ihe n'ọtụtụ injin iji belata nrụgide okpomọkụ na valves gbawara agbawa. Iji mee nke a, a na-eme valvụ ahụ oghere, oghere na-esi na ya pụta bụ ọkara jupụtara na sodium, ebe agbaze ya bụ 100 Celsius. Mgbe injin ahụ na-agba ọsọ, sodium na-agbaze ma na-aga site na oghere valvụ, na-ebufe okpomọkụ site na isi ọkụ na-ekpo ọkụ na-ekpo ọkụ na-esi na ya gaa na valve actuator.

2.2. Ijikọ valvụ na mmiri ya:

atụmatụ nke otu a dị iche iche, mana usoro a na-ahụkarị bụ ọkara cones. Site n'enyemaka nke ọkara-cones abụọ, nke na-abanye na ọwa emere na valvụ ahụ, a na-agbanye efere ahụ, nke na-ejide mmiri ma ghara ikwe ka ịtọpụ otu. Nke a na - emepụta njikọ dị n'etiti mmiri na valvụ ahụ.

2.3. Ọnọdụ oche valvụ:

N'ime igwe niile nke oge a, a na-arụpụta oche ndị na-ekpochapu iche iche na isi nke cylinder. A na-ejikwa oche ndị dị otú ahụ maka iko mmiri mgbe a na-eji alloy aluminom mee isi isi. Mgbe ọ na-agba ígwè, a na-eji akwa a na-etinye n'ime ya. Site na nhazi, oche ahụ bụ mgbanaka nke etinyere n'isi silinda na oche a rụpụtara n'ụzọ pụrụ iche. N'otu oge ahụ, a na-eme grooves mgbe ụfọdụ n'elu oche nke oche, nke, mgbe a na-agbanye ya n'oche ahụ, na-ejupụta na isi ihe isi cylinder, si otú a na-ahụ na ha nwere ntụkwasị obi. Na mgbakwunye na ịpịkọta ọnụ, enwere ike ịme mgbakwunye site na ịgbagharị n'elu. Iji hụ na mgbachi nke oghere ọrụ na-arụ ọrụ mgbe emechiri valvụ ahụ, a ga-arụ ọrụ dị n'elu oche ahụ n'otu akụkụ dị ka oghere chamfer nke isi valvụ ahụ. Maka nke a, a na-eji ihe ndị pụrụ iche na-eme ka ihe ndị ahụ jikwaa ya mee ka akụkụ ya dị elu ọ bụghị 15 ọ bụghị, 45˚ na 75˚ iji nweta teepu akara na nkuku nke 45˚ na obosara nke ihe dịka 2 mm. A na-eme nkuku ndị ọzọ iji melite mmiri na-agba gburugburu sadulu.

2.4. Valve na-eduzi Ọnọdụ:

nhazi nke ndu di iche iche. Ọtụtụ mgbe, a na-eji ntuziaka nwere ihu dị larịị, nke emere na igwe pọmpụ na-enweghị etiti. Ntuziaka ndị nwere eriri na-ejigide mpụga dị mfe iji kwado ya mana ọ siri ike ịme. Maka nke a, ọ ga-aka mma ịme channelụ maka mgbanaka nkwụsị na ntuziaka kama eriri. A na-ejikarị ntuziaka valve na-eme ihe iji chebe ha pụọ na mmetụta oxidative nke mmiri ọkụ na-ekpo ọkụ. N'okwu a, a na-eme ndị nduzi dị ogologo karị, ndị nke ọzọ dị na ọwa isi isi nke isi cylinder. Ka ebe dị n'etiti ntuziaka na isi valvụ na-ebelata, oghere dị na ntuziaka n'akụkụ akụkụ valvụ ahụ na-ebelata ma ọ bụ na-agbasawanye na mpaghara nke isi valvụ ahụ.

2.5. Springs ngwaọrụ:

na injin nke oge a, mmiri iyi kachasị na-agbapụta na-enwe mgbe nile. Iji mepụta ebe ndị na-akwado ya, a na-achịkọta ngwụsị nke eriri mmiri nke oge opupu megide ibe ha wee jikọta ha na ọkpọiso, n'ihi nke a ọnụ ọgụgụ ngụkọta nke okpukpu abụọ dị okpukpu abụọ karịa ọnụ ọgụgụ nke isi iyi ọrụ. A na-akwado eriri ngwụcha n'akụkụ akụkụ nke efere ahụ na n'akụkụ nke ọzọ nke isi cylinder ma ọ bụ ngọngọ. Ọ bụrụ na enwere ihe iyi egwu, a na-eji mmiri valvụ mee ka a na-agbanwe ya. Gia steepụ gearbox ma ọ bụ site n'otu nsọtụ mmiri ruo na nke ọzọ, ma ọ bụ site na etiti na nsọtụ abụọ. Mgbe emeghere valvụ ahụ, windings ndị dịkarịrị nso na ibe ha na-emetụ aka, n'ihi nke a ọnụ ọgụgụ nke windings na-arụ ọrụ na-ebelata, na oge nke oscillations n'efu nke oge opupu ihe ubi na-abawanye. Nke a na-ewepu ọnọdụ maka reson. Maka otu ebumnuche ahụ, mgbe ụfọdụ a na-eji isi iyi ndị na-atụgharị uche, a na-ewepụkarị ihe okike dị iche iche n'ogologo ha ma ewepu resonance.

Ugboro abụọ Akụrụngwa maka imepụta valvụ otu:

• Valves - valvụ mmiri ara ehi dị na chrome (40x), chromium nickel (40XN) na ihe ndị ọzọ alloy steels. A na-eji ígwè ndị na-ekpo ọkụ na-ekpo ọkụ na-emepụta valvụ na-ekpo ọkụ nke nwere nnukwu ọdịnaya nke chromium, nickel na metal alloying: 4Kh9S2, 4Kh10S2M, Kh12N7S, 40SH10MA.

• Oche Valve - A na-eji ígwè dị elu na-eguzogide okpomọkụ, ígwè nkedo, ọla alumini ma ọ bụ cermet.

• Ntuziaka Valve bụ gburugburu ebe siri ike ịrụpụta ma chọọ ka eji ihe ndị nwere okpomọkụ dị elu ma na-eyi nguzogide na ezigbo okpomọkụ, dị ka ihe nkedo pearlitic isi awọ na aluminum bronze.

• Springs - mere site winding waya si a spring stoma, eg 65G, 60C2A, 50HFA.

Ọrụ otu ọrụ:

3.1. Mmekọrịta usoro:

usoro mmekọrịta ejikọrọ na crankshaft, na-agagharị synchronously na ya. Ogwe oge na-emepe ma mechie ọdụ ụgbọ mmiri nke ọpụpụ na nke ọpụpụ nke otu cylinders dabere na usoro ọrụ nnabata. Nke a bụ usoro nke mgbanwe gas na cylinders.

3.2 Omume nke oge ịkwọ ụgbọala:

Oge ịgba ọsọ na-adabere na ọnọdụ nke camshaft.

• Site na ogwe ala - site na spur gears maka ịrụ ọrụ dị nro na-eji ezé nwere mmasị, na maka ịrụ ọrụ nkịtị, a na-eji textolite mee mgbanaka mgbanaka. A na-eji ngwa parasitic ma ọ bụ yinye na-enye ụgbọ ala ebe dị anya.

• N'elu aro elu - yinye rola. Ọkwa mkpọtụ dịtụ ala, nhazi dị mfe, ịdị arọ dị ala, mana sekit ahụ na-agwụ ike ma gbatịa. Site na eriri oge dabere na neoprene ejiri waya igwe mesie ike wee kpuchie ya na oyi akwa nylon na-agaghị eyi. Nhazi dị mfe, ọrụ dị jụụ.

3.3. Atụmatụ nkesa gas:

Mkpokọta mmiri na-asọpụta maka izipu gas site na valvụ ahụ dabere na oge mmeghe ya. Dị ka ị maara, n'ime igwe ọkụ anọ, maka mmejuputa ihe oriri na mkpochapu, a na-enye otu piston, nke kwekọrọ na ntụgharị nke crankshaft site na 180˚. Otú ọ dị, ahụmịhe egosila na maka njuju na nhicha nke cylinder ka ọ dị mkpa na oge nke usoro ndozi na nsị na-adị ogologo karịa akara piston kwekọrọ, ya bụ mmeghe na mmechi nke valves ekwesịghị ịrụ na isi ihe ndị nwụrụ anwụ nke piston strok, mana ụfọdụ gafere ma ọ bụ igbu oge.

A na-egosipụta oghere oghere na oge mmechi na akụkụ ntụgharị nke crankshaft ma kpọọ ya oge valve. Maka ntụkwasị obi ka ukwuu, a na-eme usoro ndị a n'ụdị chaatị (Fig 1).

valvụ mmiri na-emepekarị site n'akụkụ ihe karịrị akarị φ1 = 5˚ – 30˚ tupu piston erute n'etiti etiti nwụrụ anwụ. Nke a na-eme ka ụfọdụ akụkụ valvụ dị na mmalite nke ọrịa strok na-ejuputa ma si otú a na-eme ka njuputa nke cylinder dị mma. A na-emechi valvụ mmiri ara ahụ site na nkuku igbu oge φ2 = 30˚ - 90˚ mgbe piston gafechara etiti nwụrụ anwụ. Oge imechi valvụ mbata na-enye ohere iji oriri nke ngwakọta mmanụ ọkụ na-eme ka ọ dịkwuo mma ma mee ka ike injin dịkwuo elu.

A na-emepe valvụ ahụ iyuzucha ya na akụkụ na-agafe agafe φ3 = 40˚ - 80˚, i.e. na njedebe nke ọrịa strok, mgbe nrụgide dị na gas nke cylinder dị elu (0,4 - 0,5 MPa). Mwepụ kpụ ọkụ n'ọnụ nke cylinder gas, malitere na nrụgide a, na-eduga na nkwụsị ngwa ngwa na nrụgide na okpomọkụ, nke na-ebelata ọrụ nke ịkwanye gas na-arụ ọrụ. valvụ ahụ na-ekpocha ọkụ na-emechi na-egbu oge φ4 = 5˚ - 45˚. Nke a na-egbu oge na-enye ezigbo ihicha nke ụlọ combustion si iyuzucha gas.

Diagnostics, mmezi, mmezi:

4.1. Ihe nyocha

Diagnostic ịrịba ama:

- •Belata ike nke engine nke combustion:

- Belata nwechapụ;

- Valve ezughị ezu dabara;

- Ndọrọ valves.

• Nri oriri oriri: - Belata nwepu n’etiti valves na lifers;

- Valve ezughị ezu dabara;

- Ndọrọ valves.

• Yiri n'ime engines combustion: - Camshaft eyi;

- imeghe camshaft kam;

- Enwekwu mmetụ n'etiti oghere valvụ na valvụ bushings;

- Nnukwu nnabata n’etiti valves na lifers;

- mgbaji ọkpụkpụ, mmebi nke ekwedo nke mmiri valvụ.

• Ngosipụta nrụgide dị ala: - Ogwe valvụ ndị ahụ dị nro;

- Soft ma ọ bụ gbajiri valvụ mmiri;

- Anwụcha valvụ;

- Ọkụ isi ma ọ bụ dọwara isi cylinder

- Edozighi okpuru ekpomoku.

• Ngosipụta nrụgide dị elu. - Mbelata isi dị elu;

Usoro nyocha oge:

• Nnwale nke nrụgide na cylinder na njedebe nke mkpakọ mkpakọ. N'oge mmesho ahụ, a ga-ezute ọnọdụ ndị a: a ga-ewe iwe ọkụ ọkụ na-ere ọkụ na arụmọrụ ọrụ; A ghaghị iwepụ ihe ọkụ ọkụ; A ghaghị itinye eriri etiti nke eriri ntinye na mmanụ ma mepee ikpo ọkụ na valvụ ikuku. A na-eji ihe nchịkwa eme ihe. Ọnọdụ nrụgide dị n'etiti otu cylinders agaghị agafe 5%.

4.2. Gbanwezi nkwanye ọkụ na eriri oge:

A na-elele ma dozie oghere ọkụ site na iji akara nlele nrụgide na usoro kwekọrọ na usoro nke ọrụ injin, na-amalite site na cylinder mbụ. A na-edozi ọdịiche ahụ n'ụzọ ziri ezi ma ọ bụrụ na ọkpụrụkpụ nlele, nke kwekọrọ na ọdịiche nkịtị, gafere kpamkpam. Mgbe ị na-agbanwe nwechapụ, jigide ihe ndozi ahụ na screwdriver, mee ka mkpịsị osisi ahụ dị, tinye efere nhichapụ n'etiti eriri valvụ na njikọ ahụ, ma gbanwee nkedo na-edozi ka ịtọọ ihe achọrọ. Mgbe ahụ mkpọchi aku na-tightened.

4.3. Valve otu mmezi:

• Nrụzi valve - ihe ndị bụ isi bụ uwe na ọkụ nke conical na-arụ ọrụ n'elu, na-eyi nke azuokokoosisi na ọdịdị nke mgbawa. Ọ bụrụ na isi ọkụ ma ọ bụ mgbawa pụtara, a na-atụfu valves. A na-agbatị eriri valvụ a gbatịpụrụ na ntinye aka site na iji ngwá ọrụ. A na-eji chronization ma ọ bụ nchichi na-arụzi eriri valvụ ndị yi uwe wee gbadaa ka ọ bụrụ nha nrụzi n'ọnụ ma ọ bụ buru ibu. Elu arụ ọrụ na-eyi nke isi valvụ ahụ na-adaba na nha nrụzi. A na-atụba valvụ ndị ahụ n'oche ndị nwere mmado abrasive. A na-enyocha izi ezi nke egweri site na ịwụsa kerosene na valves hinged, ọ bụrụ na ọ naghị agbapụta, mgbe ahụ igweri dị mma maka nkeji 4-5. A naghị eweghachi isi iyi Valve, mana ejiri nke ọhụrụ dochie ya.

Ajụjụ & Azịza:

Kedu ihe agụnyere na usoro nkesa gas? Ọ dị na isi cylinder. Nhazi ya gụnyere: akwa camshaft, camshaft, valves, ogwe aka rocker, pushers, hydraulic compensators na, n'ụdị ụfọdụ, onye na-agbanwe oge.

ДKedu ebumnuche nke eriri oge injin? Usoro a na-eme ka a na-enyefe akụkụ ọhụrụ nke ikuku-mmanụ ọkụ n'oge na mwepụ nke ikuku ikuku. Dabere na mgbanwe ahụ, ọ nwere ike ịgbanwe oge nke oge valvụ.

Ebee ka usoro nkesa gas dị? N'ime engine combustion nke oge a, usoro nkesa gas dị n'elu ihe mgbochi cylinder na isi cylinder.