Honing injin mota

Abubuwa

Duk wata mota da sannu ko kuma daga baya zata samar da kayan aikinta, duk yadda aka sarrafa ta a hankali. Lokacin da aka sake yin amfani da na'urar gaba ɗaya, magabacin yana aiwatar da ayyuka masu rikitarwa da yawa waɗanda ke buƙatar cikakkiyar daidaito. Daga cikin su akwai horon silinda.

Bari muyi la'akari dalla-dalla menene asalin wannan aikin, yadda ake aiwatar dashi, kuma ko akwai wani madadin sa.

Menene honing silinda injin

Girmama injiniya hanya ce ta ƙarshe bayan sake fasalin ɓangaren wutar. Ya yi kama da lapping da gogewa, kawai a kwatanta su yana da ƙarin inganci.

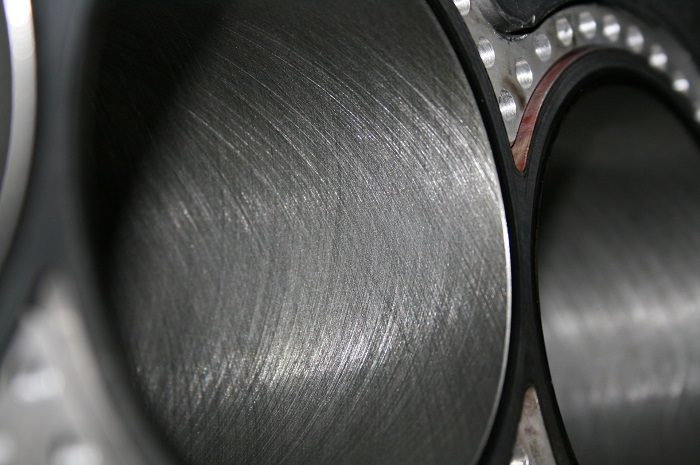

Idan kun kalli saman silinda bayan aikin, to ƙananan haɗari a cikin hanyar raga mai kyau za su kasance a bayyane a kanta. Yawancin injunan konewa na zamani suna yin wannan aikin a masana'anta.

Ya kamata a yi honing domin shugabanci, mita da kuma zurfin abin kwaikwayon su zama daidai yadda zai yiwu. Tunda wannan shine matakin karshe na gyaran injina, ana yin sa ne bayan aiki na asali, misali, idan ana buƙatar burar silinda don shigar da piston tare da ƙara diamita.

Bayan manyan gyare-gyare, silinda yana da kyakkyawa, mai santsi daidai. Don amfani da abin da ake buƙata, maigidan yana amfani da lathe ɗaya kamar na boring tare da gogewa, kawai yana amfani da hone - bututun ƙarfe na musamman. Yana ƙirƙirar tsarin ƙirar da ake buƙata tare da zurfin da ake buƙata.

Bayan yin honing, takaddun-piston-sleeve biyu zasu buƙaci ƙaramin nika lokaci fiye da sauƙaƙe bayan gyaran mara daɗi. Anan ga abubuwan da zasu iya nuna buƙatar wannan aikin:

- Matsawa ya fara fada (yadda za a auna shi da kanku, an bayyana shi daban);

- Injin ya fara cinye ƙarin mai. Baya ga matakin ragewa a cikin ramin, hayaƙin shuɗi zai bayyana daga bututun shaye shaye (ƙari, dalilan wannan lamarin an kuma bayyana su a cikin raba bita);

- Enginearfin injiniya ya ragu sosai;

- Shawagi gudu

Ba shi yiwuwa a ce da tabbaci a wane lokaci injin injin mota zai buƙaci babban garambawul (wannan batun ana yin la'akari da shi ta hanyar babban birni, saboda ba shi da hujjar tattalin arziki don haɓaka murfin silinda dabam). Wannan ya shafar yawancin masu canzawa, kamar salon tuki, abin da mai injin da mai da mai abin hawa yake amfani da shi, da sauran abubuwa.

Yana da kyau a lura cewa duk waɗannan alamun ba kai tsaye bane. Kowannensu na iya nuna wasu ɓarna a cikin injin, tsarin samar da mai, injin turbin, da sauransu.

Mafi sau da yawa, irin waɗannan matsalolin tare da tsarin haɗi mai amfani yana faruwa a cikin motoci masu nisan miloli - aƙalla dubu 100. A wannan lokacin, ana samun takamaiman ci gaba a cikin aikin silinda-piston.

Misali, tazara daga bangon silinda zuwa zoben goge mai yana ƙaruwa ƙwarai da gaske cewa man ɗin ya daina iya ƙirƙirar igiyar mai. A saboda wannan dalili, man shafawa ya kasance a saman, kuma idan aka yi hulɗa da mai ko mai na dizal, sai ya narke, saboda abin da cakuda-mai ya ƙunshi abubuwa na baƙi. Lokacin da aka kone su, sukan samar da toka mai toka.

Baya ga hayaƙin hayaƙi mai ƙarancin hayaki, motar da take da matsala makamancin haka yana raguwa cikin iko saboda ƙaran matsi. A yayin bugun shaye-shayen, wani bangare na iskar gas din yana shawagi tsakanin zobba da bangon silinda ya shiga cikin matatar injin din. Tunda direban zai tilastawa bangaren wuta aiki kamar yadda ya saba, yawan mai zai tashi sosai.

Waɗannan su ne wasu dalilai da za a buƙaci babban garambawul ga ƙungiyar. Lokacin da maigidan ya yi duk hanyoyin da ake buƙata (gundura silinda zuwa girman gyara daidai), zaku iya neman honing.

Babban manufar honing

Dalilin wannan aikin shine kamar haka. Microaramar ƙaramar halitta tana haifar da ƙaramin rauni a kan madubin silinda. Ana buƙatar kiyaye man shafawa a saman.

Kowa ya san cewa ana buƙatar mai a cikin injin silinda-piston don rage tashin hankali tsakanin zobba da bangon silinda, tare da samar da sanyaya ɗaiɗaikun sassan lokacin da ɗimbin ɗimbin yanayi ke faruwa.

A cikin rukunin wutar lantarki wanda ya yi aiki da albarkatunsa, lissafin silinda ya canza, wanda ya rage aikin motar. Innerangaren ciki na silinda a ƙarshe yana yin rauni da kaushi wanda ya bambanta da asalin ma'aunin da aka yi a masana'anta.

An gyara wannan lalacewar ta wurin gundurar silinda. Idan an riga an aiwatar da irin wannan aikin, to girman silinda ba zai ƙara dacewa da na farko ba, amma zuwa ƙimar gyara ta biyu. Bayan an gama aikin, ya zama dole ayi samfuran da suka dace tare da taimakon hone.

Bayan inganta man shafawa na saman silinda, honing yana da wata ma'ana. Wannan aikin yana cire ganga ko sifar tazara idan ta samu yayin aikin faɗaɗawa.

Yin honar motar yana tabbatar da daidaitaccen rashin daidaito, wanda yafi wahalar cimmawa tare da gogewa ko lapping. Don irin wannan gyaran ICE ya sami aikin da ake buƙata daga baya, girman ƙwayoyin da zurfin ƙididdigar dole ne su dace da matsayin masana'anta. Zamuyi magana game da yadda ake aiwatar da hanya daidai, da kuma game da ƙa'idodi jim kaɗan.

Abin da za a yi idan akwai kamewa a cikin motar

Yanzu bari mu mai da hankali kan ko zai yiwu a cire lahani idan wani abu ya faɗi, amma ba tare da rarraba sandar silinda ba. Tabbas, wannan matsalar tana da matukar wahalar ganowa ba tare da tabbatarwar gani ba. Abinda yafi dacewa shine asarar ikon injiniya da matsawa. Kamar yadda aka riga aka ambata, wannan alamar ma halayyar ƙoshin wuta ne ko gazawar tsarin mai.

Idan duk waɗannan dalilan an kawar da su, amma ba a sami sakamakon da ake so ba, to akwai babban damar yiwuwar ɓarnawa a cikin silinda (tare da ƙaramin matsewa). Ba za a iya yin watsi da wannan matsalar ba, saboda ko da ɗan matsala zai haifar da mummunan lalacewa a kan piston-silinda.

Idan masu zagin mutane har yanzu kanana ne

Abu na farko da zaka iya kokarin yi kafin ci gaba tare da wargaza injin ƙonewa na ciki shine amfani da kayan aiki wanda ke da haɗin gwaninta. Wannan wani abu ne wanda, a ƙarƙashin wasu sharuɗɗa, ƙirƙirar fim mai ƙarfi akan farfajiyar ƙarfe, yana hana ƙaruwa a cikin ƙarfin gogayya tsakanin ɓangarorin da suka lalace.

Ana ƙara waɗannan zuwa man injin. Thearin ya fara aiki dangane da halayen abubuwan haɗin. A yau akwai wadatattun irin waɗannan kuɗi. Ofayan waɗannan abubuwan shine Suprotec Active Plus, wanda kamfanin cikin gida ke ƙera shi.

Itiveara Suprotec Active Plusari a cikin man injin

Abubuwan da ke cikin wannan samfurin shine cewa kayan haɗin tribo tare da maido da saman idan bangon silinda ya ɗan lalace kaɗan (sawa ba zai wuce tentan goma na milimita ba).

Domin abun da ke ciki na suprotek yayi tasiri mai kyau, kana buƙatar bin shawarwarin masana'antun. Idan sabuntawar motar ta gudana cikin take hakkin wadannan bukatun, abu ba zai yi aiki ba.

Amfanin wannan ƙari shine cewa wuce sashi ba zai cutar da naúrar ba. Gaskiya ne, babu wani tasiri daga gare shi kuma. Saboda wadannan dalilai, dole ne a dauki wannan matakin da muhimmanci. Idan duk bukatun masana'antun sun cika, amma ba a kiyaye sakamakon da ake so ba, to matsalar ta fi tsanani.

Lokacin da kayan ƙari ba su taimaka ba

Babu wani ƙari da zai taimaka kawar da manyan rikice-rikice. A wannan yanayin, kawai kuna buƙatar cikakkiyar rarrabawar ƙarfin ƙarfin, silinda mai banƙyama da ƙwanƙwasawar fuskar su ta gaba. Matsayin matakin yin amfani da ƙididdigar daidai ba aiki ba ne. Mafi wahalar yin wasu gyare-gyare. Babban sharadin kawai shine cewa wanda zai gudanar da gyaran dole ne ya fahimci rikitarwa na musamman matakin karshe na sarrafa injina.

Ilimin aikin famfo zai zama mai amfani domin a daidaita daidaito da kusurwar sha'awar sakamakon sakamakon. A cikin yanayin gareji, ana amfani da burushi na abrasive na musamman don wannan. A wani matakin ƙwararru, hon yana kama da sanda, wanda a gefe ɗaya ana saka shi a cikin ɓarke na lathe, kuma a ɗaya hannun an sanye shi da sanduna uku tare da abin da ya dace wanda zai iya barin bayan ƙananan ƙwayoyin cuta.

Tsarin aiki da bukatun kayan aiki

M motsi na nika abin da aka makala a cikin Silinda ake bukata don daidaitaccen yanke. Idan anyi amfani da lathe, to yakamata ku sami ratayar motsi cikin sauri na tarin chuck. Mafi sau da yawa a cikin gareji, ana amfani da burushi na musamman. Sauri, ƙoƙari da santsi na motsi tuni ya dogara da ƙwarewar jiki na maigidan. Idan ya maimaita wannan aikin, zai zama mafi sauƙi a gare shi ƙirƙirar madaidaicin zane. Amma har yanzu zai bambanta da sakamako bayan amfani da hanyoyin fasaha.

Don kammala aikin, zaku buƙaci matakin da dogo mai shiryarwa. Waɗannan kayan aikin na iya taimakawa ƙirƙirar tsari iri ɗaya tare da kusurwa daidai. Idan maigidan ya ɓace, zai ɓata tsarin, saboda haka ne zai sake komai.

Saitaccen man shafawa na farfajiyar wani muhimmin abu ne wanda ake buƙata don honing motar. Saboda wannan, kerosene ko cakudarsa tare da mai yana da amfani. Wannan ruwan zai share ƙananan kwakwalwan da zasu tsoma baki tare da dacewa.

Bayan kammala aikin, dole ne a wanke naúrar da maganin sabulu. Wannan zai cire duk ƙananan ƙwayoyin, yana hana su bayyana a cikin kogon naúrar bayan haɗuwa. Bayan haka, dole ne a toshe toshilan kuma a yi amfani da shi tare da maganin gurɓataccen man.

Lokacin da motar ta haɗu, kafin a ba ta kayan da aka saba da ita, dole ne rukunin silinda-piston su shiga ciki. Wannan zai ba da damar cikakkun bayanai kan juna. A wannan lokacin, injin konewa na ciki zai buƙaci ingantacciyar hanyar dabarun canza mai da amfani da mai mai inganci.

Don ƙarin laushi mai laushi, zaka iya amfani da irin kayan masarufin Suprotek da ƙari. A wasu lokuta, ana iya yin honing ba tare da huda silinda ba. Idan lalacewar ba ta da yawa, kuma wannan aikin kawai ya isa, ba za a iya cire motar daga cikin injin ba.

Fasahar silinda

Dukkan aikin yana faruwa ne a matakai biyu. A lokacin farko, ana amfani da mafi girma abrasive. Wannan matakin ana kiransa roughing. Matakan gamawa ya riga yana buƙatar kayan aiki mai kyau. A lokaci guda yana kawo saman silinda zuwa daidaitaccen daidaiton santsi da kaushin hali.

A baya, aikin ya yi amfani da yumbu abrasives wanda aka haɗe zuwa sanduna. Zuwa yau, analogues na lu'u-lu'u sun tabbatar da kansu. Dalilin haka shine babban juriya na kayan don tsawan gajiyar aikin inji.

Kayan aiki na zamani an sanye su da hon wanda zai iya canza diamita. Wannan fasaha na guje wa muguwar silinda akan lathes. Bayan inji, diamita na Silinda na iya canzawa kaɗan, amma a cikin iyakokin gyara mai karɓa.

Ya kamata a mai da hankali sosai don sarrafa injina iri biyu. Gyaran gyare-gyaren riga ya ɗan bambanta da tsari iri ɗaya don analogs marasa hannu.

Hannun iska mara motsi

Hanya mafi sauki wajan horas da motoci marasa inganci. Don wannan, toshewar bulon ɗin an shigar dashi akan inji. Jiki ya matse, saitin da ake buƙata an saita akan hone kuma an samar da mai sanyaya.

Dogaro da wane kayan aikin da aka yi amfani da su, da kuma gwargwadon aikin da ake buƙatar yin aikin, lokacin aiki zai bambanta. Yana da mahimmanci maigida ya tabbatar da cewa harsashi zai motsa a cikin madaidaiciyar shugabanci, kuma an gyara bulo ɗin kamar yadda ya yiwu don kada ya yi tuntuɓe.

Sakamakon honing ana sarrafa shi ta hanyar gage na ciki (kayan aikin da ke auna diamita na ciki tare da tsawon tsawon samfurin). A cikin bitoci masu mahimmanci, ana amfani da na'urori don ƙayyade matakin ƙarancin yanayin da aka gama.

Sleeve Motors

Abubuwan da ke tattare da irin wannan motar shine cewa sauye sauye a cikin su an ɗan sauƙaƙa shi. Mai motar ya sayi saitin layi don takamaiman ƙungiyar wutar lantarki. Yana da mahimmanci don tabbatar da cewa waɗannan ɓangarorin sun wuce aikin honing. In ba haka ba, samfurin ba zai yi aiki na dogon lokaci ba.

Lokacin da aka sayi irin waɗannan samfuran, masana'antun na iya tabbatar da cewa samfurin ya shirya don shigarwa kuma baya buƙatar saka shi cikin ƙarin aiki. Tunda babban birnin injin yana da tsada, yana da kyau ka gani da kanka. Kuna buƙatar tambayar mayen don bincika ko duk sifofin wannan nau'in samfurin an kiyaye su da gaske a masana'antar.

Don aiwatar da layuka a cikin bitar, dole ne a sami matattara na musamman kama da jikin toshe silinda. An gyara shi a kan gadon na'ura tare da ƙarfin ƙarfafa ƙarfin ƙarfe don kar ya lalata hannayen riga, amma a lokaci guda kar a basu izinin motsawa.

Sabbin hannayen riga ana sarrafa su a matakai hudu:

- An cire m karfe Layer (a wasu lokuta sun gundura);

- Yin magana tare da abrasive 150 grit;

- Irin wannan aiki tare da ƙarami hatsi (daga 300 zuwa 500);

- Tsabtace farfajiyar daga ƙurar ƙarfe tare da goge nailan ta amfani da manna mai ɗauke da lu'ulu'u na silinon.

Sakamakon zalunci da mafita

Anan akwai babban sakamakon idan injin ya ci nasara:

| Matsalar aiki na samfur: | Alama: | Matsalar da ka iya yiwuwa: |

| An ƙirƙira ƙone mai mai ƙwarai saboda gaskiyar cewa zoben mai ƙwanƙwasa mai ba ya cire maiko mai yawa | Motar ta fara ɗaukar mai mai yawa (a sigar da ba a kula da ita ba, har zuwa lita ɗaya a kilomita dubu ɗaya.) | Yi amfani da ƙari daga Suprotek Active Plus; Idan kayan aikin ba zai taimaka ba, dole ne a fara sake fasalin injin ƙonewa na ciki |

| Noarfin mai ya ƙaru sosai saboda gaskiyar cewa yana haɗuwa da cakuda-mai kuma yana ƙonewa a cikin silinda | Baya ga yawan amfani da man shafawa, za a fitar da hayaƙin shuɗi mai yawa daga bututun shaye-shaye. | Zuba abubuwan haɗin tribo a cikin man; Tare da ƙananan rikice-rikice, honing zai canza yanayin ba tare da wargaza ƙungiyar ba |

| Yawan piston da na silinda sun karye | Banza ya juya "yawo" | Idan tsarin mai yana aiki mai kyau, ƙonewa kuma babu kurakurai a cikin sashin kulawa, wannan alama ce ta alama ta alamun kamawa. A matakan farko, mai Plusari mai Plusari zai taimaka, a cikin matakan ci gaba, ana buƙatar m da honing mai zuwa. |

| Iskar hayaƙi sun ɓarke cikin matatar | Amfani da mai ya karu (don kula da ƙarfi a daidai matakin, kuna buƙatar danna ƙwanƙolin gas da ƙarfi kuma juya ƙwanƙwasa) | A wasu lokuta, ma'ana tare da abun da ke tattare da tsarin iya taimakawa. Koyaya, rakiyar rashin aiki (alal misali, ƙonewar fistan) zai buƙaci ɓarnawar motar ko ta wani ɓangare. Babu wata hanyar da za a iya gano takamaiman dalilin asarar wutar. |

Kodayake ana iya yin honing na motsa jiki a gida ta amfani da rawar motsawa da kayan aikin inji, ingancin wannan hanyar zai zama mara kyau. Bayan irin wannan magani, scuffs ya samar a cikin motar da sauri, wanda zai gajarta tazarar da ke tsakanin sake fasalin ɓangaren wutar.

Tunda babban birnin injin ƙone-ƙone na cikin gida yana da iyakance kansa akan yawan ayyuka iri ɗaya, ya fi kyau a ba da honing ga ƙwararrun da ke aiki a kan kayan aiki na zamani. Kayan lantarki zasuyi aiki mai kyau fiye da hanyar "ta ido".

Don kwatancen, duba yadda aikin hodar silinda kai tsaye don wuce gona da iri akan kayan aikin zamani:

Tambayoyi & Amsa:

Menene honing don me? Wannan shi ne don rage rashin ƙarfi a kan ganuwar Silinda. Hakanan ana buƙatar don hanzarta shigar da zoben piston. Honingovka yana ƙara rayuwar sabis na injin konewa na ciki bayan babban birnin.

Menene Block Honing? Wannan hanya ce da aka yi amfani da raga mai kyau a bangon silinda. Yana ba da riƙewar man inji, wanda ke inganta lubrication na zoben piston kuma yana daidaita hawan mai.