All about engine camshaft

Content

Engine camshaft

For the stable operation of the internal combustion engine, each part plays an important function. Among them is a camshaft. Consider what its function is, what malfunctions occur, and in which cases it needs to be replaced.

What is a camshaft

In internal combustion engines with a four-stroke type of operation, the camshaft is an integral element, without which fresh air or an air-fuel mixture will not enter the cylinders. This is the shaft mounted in the cylinder head. It is needed so that the intake and exhaust valves open in a timely manner.

Each camshaft has cams (drop-shaped eccentrics) that press on the piston follower, opening the corresponding hole in the cylinder chamber. In classic four-stroke engines, camshafts are always used (there can be two, four or one).

Principle of operation

A drive pulley (or an asterisk, depending on the type of timing drive) is fixed from the end of the camshaft. A belt (or chain, if an asterisk is installed) is put on it, which is connected to the pulley or sprocket of the crankshaft. During the rotation of the crankshaft, torque is supplied to the camshaft drive through a belt or chain, due to which this shaft turns synchronously with the crankshaft.

The cross section of the camshaft shows that the cams on it are drop-shaped. When the camshaft turns, the extended part of the cam pushes against the valve tappet, opening the inlet or outlet. When the intake valves are opened, fresh air or an air-fuel mixture enters the cylinder. When the exhaust valves are opened, exhaust gases are removed from the cylinder.

The design feature of the camshaft allows you to always open / close the valves at the right time, ensuring efficient gas distribution in the engine. Therefore, this part is called the camshaft. When the shaft torque is shifted (for example, when the belt or chain is stretched), the valves do not open in accordance with the stroke performed in the cylinder, which leads to unstable operation of the internal combustion engine or does not allow it to work at all.

Where is the camshaft located?

The location of the camshaft depends on the design features of the motor. In some modifications, it is located below, under the cylinder block. Modifications of engines are more common, the camshaft of which is located in the cylinder head (on top of the internal combustion engine). In the second case, the repair and adjustment of the gas distribution mechanism is much easier than in the first.

Modifications of V-shaped engines are equipped with a timing belt, which is located in the collapse of the cylinder block, and sometimes a separate block is equipped with its own gas distribution mechanism. The camshaft itself is fixed in the housing with bearings, which allows it to rotate continuously and smoothly. In boxer engines (or boxer), the design of the internal combustion engine does not allow the installation of one camshaft. In this case, a separate gas distribution mechanism is installed on each side, but their work is synchronized.

Camshaft functions

Camshaft - timing element (gas distribution mechanism). It determines the cycle order of the engine and synchronizes the opening / closing of the valves, which feed the air-fuel mixture into the cylinders and exhaust the exhaust gases.

The gas distribution mechanism works according to the following principle. At the time of starting the engine, the starter cranks bonesth shaft. The camshaft is driven by a chain, a belt mounted on a crankshaft pulley or gears (in many old American cars). The inlet valve opens in the cylinder, and a mixture of gasoline and air enters the combustion chamber. At the same moment, the crankshaft sensor supplies a pulse to the ignition coil. It generates a discharge that goes to spark plug.

By the time a spark appears, both valves in the cylinder are closed and the fuel mixture is compressed. During ignition, energy is generated and the piston moves down. So the crankshaft rotates and sets the camshaft in motion. At this point, he opens the exhaust valve through which the exhaust gases from the combustion process exit.

The camshaft always opens the desired valve for a specific period of time and at a standard height. Due to its shape, this element provides a stable cycle of cycle change in the motor.

Details of the valve opening and closing phases, as well as their settings, are shown in this video:

Depending on the engine modification, one or more camshafts can be installed in it. In most vehicles, this part is located in the cylinder head. It is driven by the rotation of the crankshaft. These two elements are connected using a belt, timing chain or gear.

Most often, a single camshaft is equipped with an in-line engine with an in-line arrangement of cylinders. Most of these engines have two valves per cylinder (one inlet and one exhaust). There are also modifications with three valves per cylinder (two at the inlet, one at the outlet). Two shafts are more often equipped with engines in which 4 valves per cylinder. In opposed internal combustion engines and with a V-shaped, two camshafts are also installed.

Motors with a single camshaft have a simple design, which leads to lower unit costs during the manufacturing process. Such modifications are easier to maintain. They are always installed on budget cars.

On more expensive engine modifications, some manufacturers install a second camshaft to reduce the load (compared with the single-shaft timing options) and in some ICE models to provide a phase shift of the gas distribution. Most often, such a system is found in cars that must differ in sports characteristics.

The camshaft always opens the valve for a specific period of time. To improve the efficiency of the engine at higher speeds, it is necessary to change this interval (the engine needs more air). But with the standard setting of the gas distribution mechanism at increased crankshaft speeds, the inlet valve closes before the desired amount of air enters the chamber.

At the same time, if you install a sports camshaft (cams open the intake valves for longer and to a different height), at low engine speeds there is a high probability that the intake valve will open before the exhaust valve closes. Because of this, part of the mixture will fall into the exhaust system. As a result, power loss at low speeds and increased exhaust toxicity.

The simplest scheme to achieve this effect is to install a camshaft with a cranking function at a certain angle relative to the crankshaft. This mechanism allows for early and late closing / opening of the intake and exhaust valves. At speeds up to 3500 it will be in one position, and when this threshold is overcome, the shaft rotates a little.

Each manufacturer equipping its cars with such a system indicates its own marking in the technical documentation. For example, Honda specifies VTEC or i-VTEC, Hyundai specifies CVVT, Fiat - MultiAir, Mazda - S-VT, BMW - VANOS, Audi - Valvelift, Volkswagen - VVT, etc.

To date, in order to increase the performance of power units, electromagnetic and pneumatic camless gas distribution systems are being developed. So far, such modifications are very expensive to manufacture and service, so they are not yet installed on production cars.

In addition to the distribution of engine cycles, this part drives additional equipment (depending on the modification of the motor), for example, oil and fuel pumps, as well as a distributor shaft.

Camshaft design

Camshafts are made by forging, solid casting, hollow casting and tubular modifications have recently appeared. The purpose of changing the technology of creation is to facilitate the design to obtain maximum engine efficiency.

The camshaft is made in the form of a rod on which there are such elements:

- Sock. This is the front of the shaft in which the keyway is made. The timing belt pulley is installed here. In the case of a chain drive, an asterisk is installed in its place. This part is fixed with an end bolt.

- Neck of an epiploon. An oil seal is attached to it, preventing the leakage of lubricant from the mechanism.

- Support neck. The number of such elements depends on the length of the rod. Support bearings are mounted on them, which reduce the friction force during rotation of the rod. These elements are installed in the corresponding grooves in the cylinder head.

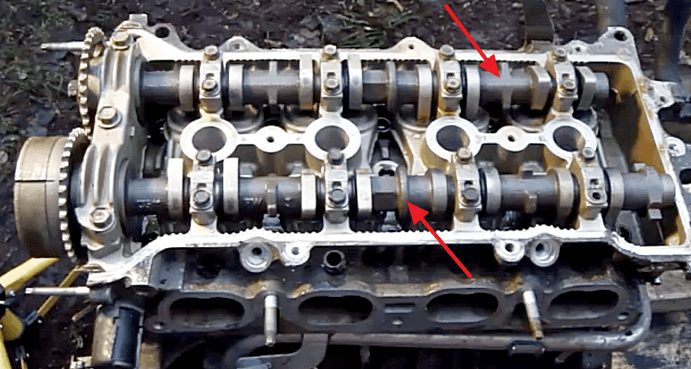

- Cams. These are protrusions in the form of a frozen drop. During rotation, they push the rod attached to the rocker arm (or the valve pusher itself). The number of cams depends on the number of valves. Their size and shape affects the height and duration of valve opening. The sharper the peak, the faster the valve closes. And vice versa - a gentle edge slightly holds the valve open. The thinner the cam axis, the lower the valve will lower, which will increase fuel volume and accelerate exhaust gas exhaust. According to the shape of the cams, the type of gas distribution phases is determined (narrow - at low revs, wide - at high).

- Oil channels. A through hole is made inside the shaft, through which oil is supplied to the cams (each one has a small outlet). This prevents premature erasure of the pusher rods and production on the cam planes.

If a single camshaft is used in the design of the motor, then the cams in it are arranged so that one set moves the intake valves, and a slightly biased set - exhaust. In engines, the cylinders of which are equipped with two valves for inlet and two for exhaust, two camshafts are installed. In this case, one opens the inlet valves, and the other opens the exhaust gas.

Types

Basically, the camshafts are not fundamentally different from each other. Gas distribution mechanisms differ radically in different engines. For example, in ONS systems, the camshaft is installed in the cylinder head (above the block), and directly drives the valves (or through pushers, hydraulic lifters).

In OHV-type gas distribution mechanisms, the camshaft is located next to the crankshaft at the bottom of the cylinder block, and the valves are actuated via pushrod rods. Depending on the type of timing, either one or two camshafts per cylinder bank can be installed in the cylinder head.

The camshafts differ among themselves in the type of cams. Some have more elongated "drops", while others, on the contrary, have a less elongated shape. This design provides a different amplitude of valve movement (some have a longer opening interval, while others open longer). Such features of the camshafts provide ample opportunities for tuning engines by changing the torque and quantity of the VTS supply.

Among the tuning camshafts there are:

- Grassroots. Provides the motor with maximum torque at lower rpms, which is great for city driving.

- Bottom-middle. This is the golden mean between low and medium revs. This camshaft is often used on drag racing machines.

- Horse. In motors with such camshafts, the maximum torque is available at maximum revs, which has a positive effect on the maximum speed of the car (for driving on the highway).

In addition to sports camshafts, there are also modifications that open both groups of valves (both intake and exhaust valves at the appropriate time). For this, two cam groups are used on the camshaft. DOHC timing systems have individual intake and exhaust camshafts.

What is the camshaft sensor responsible for

In engines with a carburetor, a distributor is connected to the camshaft, which determines which phase is performed in the first cylinder - inlet or outlet.

There is no distributor in the injection ICE, therefore, the camshaft position sensor is responsible for determining the phases of the first cylinder. Its task is not identical to the functionality of the crankshaft sensor. For one full revolution of the timing belt, the crankshaft will rotate around its axis twice.

DPKV fixes the TDC of the piston of the first cylinder and gives an impulse to the formation of a discharge for the spark plug. DPRV sends a signal to the computer, at what point you need to apply fuel and a spark to the first cylinder. The cycles in the remaining cylinders occur alternately depending on the design of the engine.

The camshaft sensor consists of a magnet and a semiconductor. On the timing shaft in the area where the sensor is installed, there is a benchmark (small metal tooth). During rotation, this element passes by the sensor, due to which the magnetic field in it closes and a pulse is generated that goes to the computer.

The electronic control unit captures the speed of the pulses. According to them, he is guided when in the first cylinder to supply and ignite the fuel mixture. In the case of installing two shafts (one per intake stroke, and the other - exhaust), will be installed on the sensor on each of them.

What happens if the sensor fails? This video is dedicated to this issue:

Watch this video on YouTube

If the motor is equipped with a variable valve timing system, then the computer determines the pulse frequency of the valve opening / closing, depending on the pulse frequency. In this case, the engine will be equipped with an additional device - a phase shifter (or hydraulic clutch), which cranks the camshaft to change the opening time. If the Hall sensor (or camshaft) is faulty, then the valve timing will not change.

The principle of operation of the DPRV in diesel engines differs from the use in gasoline analogues. In this case, it fixes the position of all pistons at top dead center at the time of compression of the fuel mixture. This allows you to more accurately determine the position of the camshaft relative to the crankshaft, which stabilizes the operation of the diesel engine and facilitates its launch.

Additional sensors have been added to the design of such sensors, the position of which on the master disk corresponds to the slope of a particular valve in a separate cylinder. The device of such elements may differ depending on the proprietary developments of different manufacturers.

Types of camshaft placement in the engine

Depending on the type of engine, it can contain one, two, or even four shafts of a gas distribution mechanism. To make it easier to determine the type of timing, the following markings are applied to the cylinder head cover:

- SOHC. It will be an in-line or V-shaped engine with two or three valves per cylinder. In it, the camshaft will be one on a row. On its core there are cams that control the intake phase, and slightly displaced - responsible for the exhaust phase. In the case of motors made in the form of V, there will be two such shafts (one per row of cylinders) or one (placed in the camber between the rows).

- DOHC. This system differs from the previous one by the presence of two camshafts on one row of cylinders. In this case, each of them will be responsible for a separate phase: one for the inlet, and the other for the outlet. There will be two on the single-row shaft motors, and four on the V-shaped ones. This technology allows you to reduce the load on the shaft, which increases its resource.

Gas distribution mechanisms also differ in the placement of shafts:

- Side (or bottom) (OHV or “Pusher” engine). This is an old technology that was used in carburetor engines. Among the advantages of this type is the ease of lubrication of moving elements (located directly in the crankcase). The main disadvantage is the complexity of maintenance and replacement. In this case, the cams press on the rocker pushers, and they transmit movement to the valve itself. Such modifications of motors are ineffective at high speeds, since they contain a large number of valve opening timing controls. Due to the increased inertia, the accuracy of the valve timing suffers.

- Upper (OHC). This timing design is used in modern engines. This unit is easier to maintain and repair. One of the drawbacks is the complex lubrication system. The oil pump must create a stable pressure, so it is necessary to closely monitor the intervals for changing the oil and filter (what to focus on when determining the schedule of such work is described here) Such a device allows the use of fewer additional parts. In this case, the cams act directly on the valve followers.

How to detect a camshaft defect

The main reason for the failure of the camshaft is oil starvation. It may occur due to bad filter status or inappropriate oil for this motor (by what parameters is the lubricant selected, read separate article) If you observe the maintenance intervals, the timing shaft will last as much as the entire engine.

Common camshaft problems

Due to the natural wear and tear of the parts and the motorist’s oversight, the following malfunction of the camshaft may occur.

- Failure of attached parts - drive gear, belt or timing chain. In this case, the shaft becomes unusable and needs to be replaced.

- Scuffing on the supporting journals and working out on the cams. Chips and grooves appear due to excessive loads, for example, as a result of improper valve adjustment. During rotation, the increased frictional force between the cams and pushers creates additional heating of the assembly, destroying the oil film.

- Oil seal leakage. It occurs as a result of prolonged downtime of the motor. Over time, the rubber seal loses its elasticity.

- Shaft deformation. Due to overheating of the motor, the metal element may bend under heavy load. Such a malfunction is detected by the appearance of additional vibration in the engine. Typically, this problem does not last long - due to strong shaking, the adjacent parts will quickly fail, and the motor will need to be sent for overhaul.

- Incorrect installation. This in itself is not a malfunction, but due to non-compliance with the standards for tightening bolts and adjusting the phases, the internal combustion engine will quickly become unusable, and it will need to be "capitalized".

- Poor quality of the material can lead to damage to the shaft itself, therefore, when choosing a new camshaft, it is important to pay attention not only to its price, but also to the reputation of the manufacturer.

How to visually determine cam wear - shown in the video:

Watch this video on YouTube

Some motorists try to eliminate some malfunctions of the timing shaft by polishing damaged areas or installing additional liners. In such repair work there is no point, because when they are performed it is impossible to achieve the accuracy necessary for the smooth operation of the unit. In the event of a problem with the camshaft, experts recommend immediately replacing it with a new one.

How to choose a camshaft

The new camshaft must be selected based on the reason for the replacement:

- Replacing a damaged part with a new one. In this case, instead of a failed model, a similar one is selected.

- Modernization of the engine. For sports cars, special camshafts are used in conjunction with a variable valve timing system. Motors for everyday driving are also being upgraded, for example, increasing power by adjusting the phases by installing non-standard camshafts. If there is no experience in performing such work, then it is better to entrust it to professionals.

What should I focus on when choosing a camshaft custom for a specific engine? The main parameter is cam camber, maximum valve lift and overlap angle.

To see how these indicators affect engine performance, see the following video:

Watch this video on YouTube

The cost of a new camshaft

Compared with the overhaul of the entire engine, the cost of replacing the camshaft is negligible. For example, a new shaft for a domestic car costs around $ 25. For the adjustment of the valve timing in some workshops will take 70 cu For major repairs of the motor, along with spare parts, you will have to pay about $ 250 (and this is in the garage service stations).

As you can see, it is better to carry out maintenance on time and not expose the motor to excessive loads. Then he will serve his master for many years.

Which brands to give preference to

The working resource of the camshaft directly depends on how high-quality material the manufacturer uses when creating this part. Soft metal will wear out more, and overheated metal can burst.

The highest quality and most reliable option is the OEM company. It is a manufacturer of various original equipment, whose products may be sold under different brand names, but the documentation will indicate that the part is OEM.

Among the products of this manufacturer, you can find a part for any car. True, the cost of such a camshaft will be very expensive compared to analogs of specific brands.

If you need to stay on a cheaper camshaft, then a good option are:

- German brand Ruville;

- Czech manufacturer ET Engineteam;

- British brand AE;

- Spanish firm Ajusa.

The disadvantages when choosing a camshaft from the listed manufacturers is that in many cases they do not create parts for a specific model. In this case, you will need to either buy the original, or contact a trusted turner.

Questions and answers:

How does the crankshaft and camshaft work? The crankshaft works by pushing the piston in the cylinders. A timing camshaft is connected to it through a belt. For two crankshaft revolutions, one camshaft rotation occurs.

What is the difference between a crankshaft and a camshaft? The crankshaft, rotating, drives the flywheel into rotation (then the torque goes to the transmission and to the drive wheels). The camshaft opens / closes the timing valve.

What are the types of camshafts? There are grassroots, riding, tuning and sports camshafts. They differ in the number and shape of the cams that drive the valves.