Brake discs: types, properties, practice of use.

The brake system of a car is a key element of car safety. And there is hardly a motorist who has not encountered the selection and replacement of consumables: brake fluid, pads, discs. Here we will talk about the types of the latter in more detail today.

Generally speaking, you can do without this information - for this you can simply buy original brake discs and not bother with technical subtleties. Or rely on the recommendations of a specialized store and stop at the recommended offer. However, the market is developing, and along with it, new technologies appear that promise certain bonuses to users. Therefore, here - informed, means armed.

So, the basic classification constructively divides brake discs into three subgroups:

– non-ventilated (or solid). Usually installed on a less loaded rear axle. They got their name because of their design: they are made from a solid billet of cast iron and do not have an internal cavity for ventilation.

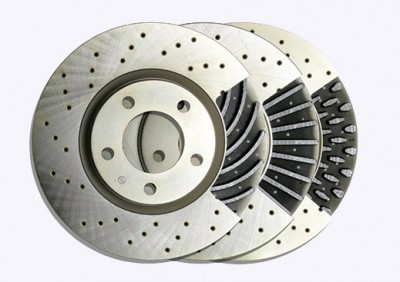

- ventilated. This type consists of two disks interconnected by jumpers, forming a cavity for ventilation. Because they have improved cooling, they are a more efficient version of a solid design. As a rule, they are installed on the front axle. Large SUVs and cars with a capacity of 200 or more horsepower are equipped with ventilated discs both front and rear.

- two-part. More modern development. As the name implies, it consists of two prefabricated elements - the hub part and the working canvas, interconnected by pins. They are used on premium models, solving two problems: reducing unsprung weight, as well as improving heat dissipation from the disk. This technology is standardly equipped with modern models of BMW, Audi, Mercedes.

Speaking of constructive classification, the motorist has no choice - to install a solid or ventilated disc. In this situation, the type is determined by the vehicle manufacturer. In other words, if a non-ventilated part is provided on the rear axle of your car, then it will simply be impossible to put a disc with ventilation - this will not allow the design of the brake caliper. The same is true for two-part components.

In addition to design features, brake discs are also divided into types of execution (regardless of the presence or absence of ventilation).

- Smooth. The most common type, which is installed in 95% of cases regularly, on the factory conveyor. They have a smooth polished surface and, in fact, are considered the basic type.

– Perforated. This variation is considered a smooth disk upgrade. They are distinguished by the presence of a through perforation made perpendicular to the working surface. In the classics, when perforated components were just starting to be mass-produced, the disc had 24 to 36 holes. Now there are parts on the market that have 8-12 holes, which perform a faster decorative function. Perforation solves two applied problems: it accelerates the cooling of the brake disc, and also removes combustion products from the “spot” of the disc-pad contact.

- Discs with a radial notch. Also, it is considered a functional refinement of the smooth type. Distinguished by a groove milled on the surface, located at an angle to the hub, extending from the outer edge of the part. The practical task of the radial notch is to divert waste material, dust and water from the “spot” of contact with the block.

– Perforation with notches. This is essentially a combination of the two options above. On the surface of the disk, drilling is applied in the amount of 18 to 24 holes most often, as well as 4-5 radial notches. Performs the tasks of both through holes and radial recesses at the same time. By the way, the most popular tuning of brake discs in many markets.

In the case of performance types, the motorist has a choice. That is, both smooth and perforated discs will be made strictly according to standard sizes, and will not require any modifications during installation. Therefore, knowing the tasks of a particular option, the driver can select and install any of them on the car.

Separately, it would be possible to consider a classification by material, since in addition to traditional cast-iron discs, serial cars are also equipped with composite carbon-ceramic discs, but the percentage of the latter is negligible, so the above categorization will be relevant for 99% of cars.