Connecting rod - design, work. What are the most common connecting rod bearing problems? Learn about the design of the crank system

Content

- Rod, head and other elements - connecting rod design

- Connecting rod design - how does it work?

- Connecting rod with engine bearing assembly

- Connecting rod bearing shells - causes of malfunctions

- Connecting Rod Bearing Degradation - Symptoms

- Inverted cup - symptoms and consequences

- The connecting rod bearing has turned - what to do?

- What torque should the connecting rod bearings be tightened to?

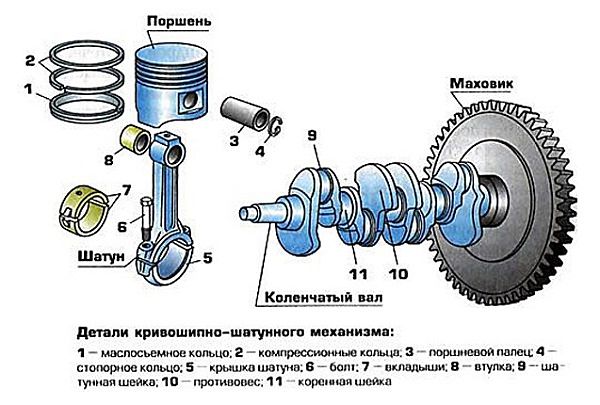

Rod, head and other elements - connecting rod design

The most important elements of the connecting rod are:

- head;

- root;

- evaluate;

- covers the legs

- connecting rod bearing shells;

- connecting rod bolts.

Connecting rod design - how does it work?

To provide better resistance to impact loads, the connecting rod shank is made of an I-beam design. Due to this, high resistance to temperature changes, a change in the direction of the energy impact and the need to convert reciprocating motion into rotational motion is maintained.

The connecting rod end is connected directly to the piston by means of a sliding sleeve. Oil lubrication provided by oil mist or a hole in the element shaft must be used.

The leg allows connection to the crankshaft. For its rotation, connecting rod bearing shells are required. Their use is necessary to ensure friction reduction. As a rule, it has notches for uniform distribution of lubricant.

Connecting rod with engine bearing assembly

In the materials relating to patents, you will find a specific solution of the Polish designer. This applies to a connecting rod with a bearing assembly. What is its structure? A feature of the connecting rod with a bearing assembly is the use of half-shells of connecting rod heads with an additional ball lock. Thanks to this solution, it is possible to balance the deflection angle and axial clearance in crank-piston systems. The paw mounted on the crankshaft is not rigid, but oscillates with bearings. This solution was patented but not mass-produced.

Connecting rod bearing shells - causes of malfunctions

The design of connecting rod bearings is very simple. The huge forces acting on the connecting rod bearings cause wear. The most common causes of accelerated destruction of connecting rod bearing shells are:

- negligence in oil intervals;

- driving a car at high engine speeds;

- fast acceleration at low rpm and high gears.

Connecting Rod Bearing Degradation - Symptoms

Progressive wear is most often manifested by knocking during sharp acceleration while driving. This is caused by the resulting clearance between the bushings and the shaft. The connecting rod bearing shells show signs of wear due to the separation of small chips that can get on the oil filter or during removal. oil collection. If you see them in your engine, know that it will be overhauled soon. And this means significant costs, often disproportionate to the cost of the car.

Inverted cup - symptoms and consequences

If the bearing shells are not repaired in time, very serious damage can occur. A rotating bearing causes symptoms such as noise when the engine is idling. Depending on the unit, this can be more or less annoying, but you cannot continue to operate the car with this type of malfunction. The unit is in need of a major overhaul.

The connecting rod bearing has turned - what to do?

Unfortunately, this is the start of an engine overhaul. First, unscrew the legs of all connecting rods and remove the crankshaft. The crankshaft may need to be regenerated. The price includes its inspection and polishing. Depending on the model, it can fluctuate within a few hundred zlotys. In extreme cases, the damaged element cannot be repaired and a new one must be purchased.

What torque should the connecting rod bearings be tightened to?

If you've made it to this stage of the repair, great. Information about your car model can be found in the service book. Strictly observe the tightening torque so as not to jam the bushings once again and damage the assembly. Therefore, before doing it yourself, make sure what values are provided by the manufacturer.

As you can see, connecting rod bearings are an extremely important element of the crank-piston system. You should buy products only from trusted and respected brands, and entrust the installation to professionals. However, before carrying out the necessary repairs, we recommend that you take care of your unit and regularly change its working fluids. This will extend the time of trouble-free driving.