Renault Hybrid System Operation

Content

Hybrid Assist is a low cost hybridization system that is compatible with any transmission. Its lightness-focused philosophy is to help the engine rather than offer a 100% electric mode that requires lots of batteries and a powerful electric motor. So let's see together how this process, called "Hybrid Assist", works, and which uses a method very similar to Stop and Start.

See also: different hybrid technologies.

What are the others doing?

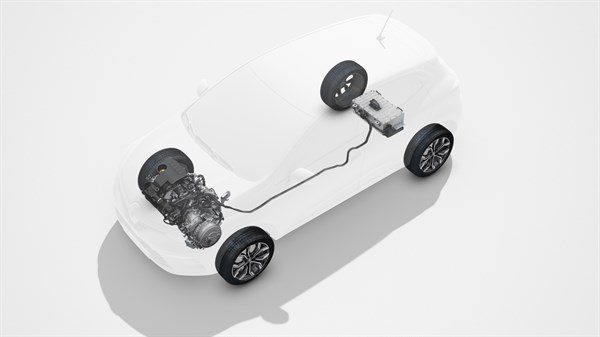

While we used to have an electric motor in front of the gearbox (between the engine and gearbox, called a parallel hybrid system) on the most common hybrids, Renault, and now many manufacturers, had the idea to place it in auxiliary pulleys.

As you can see here, the electric motor is usually built into the output of the engine towards the gearbox (and therefore the wheels). When you switch to 100% electric, the heat engine is shut off and the transmission can steer the car on its own thanks to the electric motor located just behind it, which takes in the heat. Thus, most plug-in hybrids allow for more than 30 km of travel in all electric vehicles.

Renault system: hybrid assistant

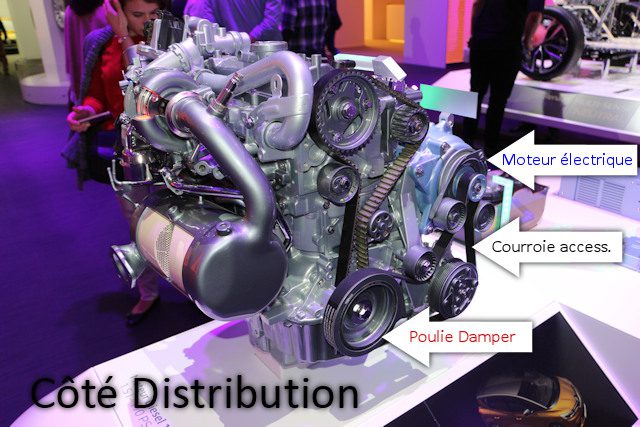

Before talking about the location of the electric motor in the Renault system, let's take a look at the classics ... The heat engine has a flywheel on one side, on which the clutch and starter are grafted, and on the other, the timing. belt (or chain) and belt for accessories. The distribution synchronizes the moving parts of the engine, and the auxiliary belt transfers power from the engine to various parts to generate power (this can be an alternator, high pressure fuel pump, etc.).

Here are the images to clarify the situation:

On this side, we have a distribution and auxiliary belt that are parallel. The damper pulley, marked in red, is directly connected to the engine crankshaft.

As you can imagine, at Renault we decided to help the engine on the distribution side instead of the generator. Therefore, we can view this hybrid system as a “super” stop and start system, because instead of being limited to restarting the engine, it helps the engine run continuously. It is a small electric motor (hence a generator with a rotor and stator). 13.5 hours who brings 15 Nm additional torque to the heat engine.

Therefore, it is not about offering a heavy and expensive plug-in hybrid system, but about further dramatic reductions in consumption, especially for the NEDC standard ...

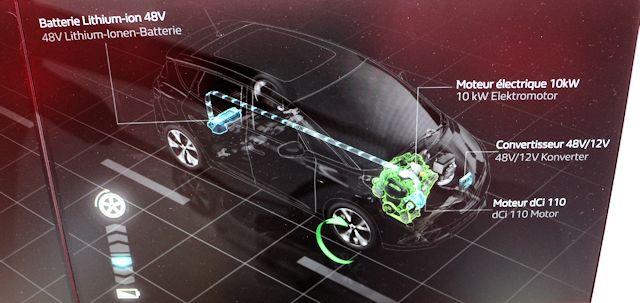

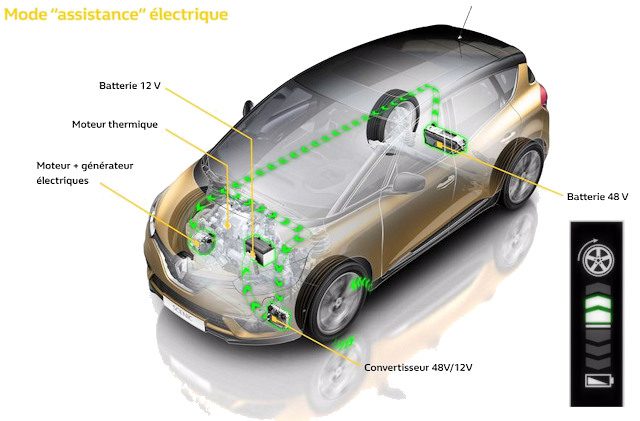

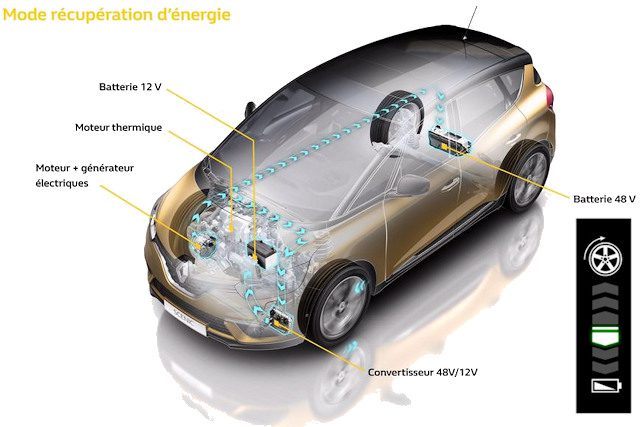

This gives the following schematically:

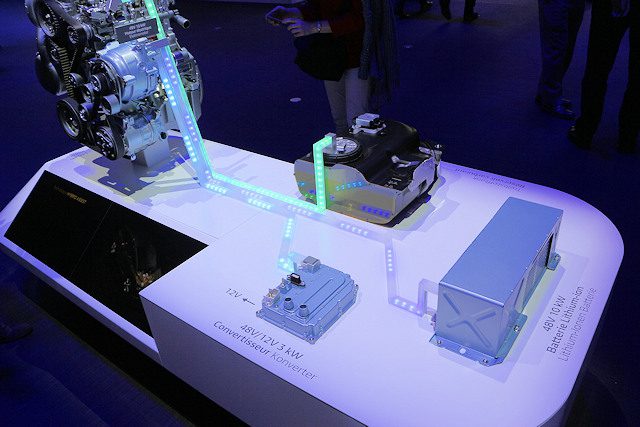

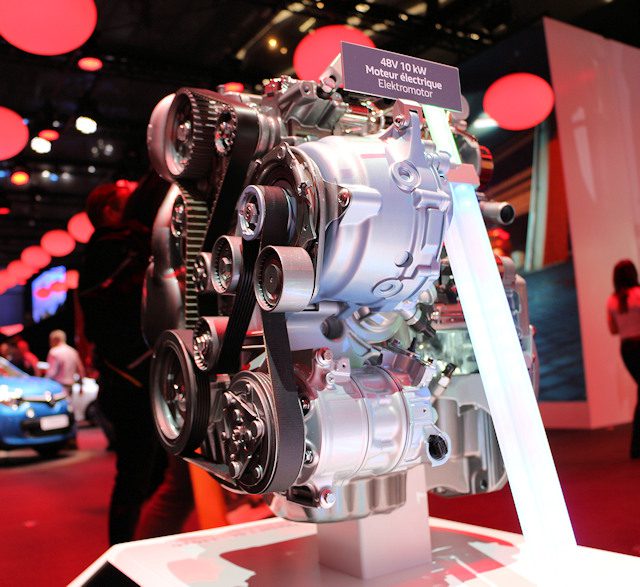

In fact, as Renault exhibited at the 2016 Geneva Motor Show, it looks like this:

Thus, the electric motor is connected to the accessory belt and not to the distributor, but only next to it.

Power consumption and recharging

You may know that the magic of the electric motor allows you to use it reversible... If I send a current inward, it starts to rotate. On the other hand, if I run the engine alone, it will generate electricity.

Therefore, when the battery directs power to the electric motor, the latter then drives the crankshaft through the damper pulley (and therefore assists the heat engine). Conversely, when the battery is low, the heat engine turns on the electric motor (because it is connected to an auxiliary belt), which sends the generated electricity to the battery. Because an electric motor (rotor/stator) is ultimately just an alternator!

Therefore, it is enough for the engine to run to charge the battery, which is already produced by the alternator in your car ... Energy is also recovered when braking.

Pros and cons

Among the advantages is the fact that this is an easy solution that allows you to avoid a significant overbalance, as well as limit the cost of the purchase. Because at the end of the day, a hybrid car is a paradox: we equip the car to make it more fuel efficient, but because of the extra weight, it takes more energy to move it…

Also, I repeat, this very flexible process can be used anywhere: in a manual or automatic transmission, on gasoline or diesel.

On the other hand, this lightweight solution does not allow a fully electric drive to be controlled, since the heat engine is located between the electric motor and the wheels ... The electric motor is losing too much energy to shut down the engine.

Renault Sheets