Checking glow plugs on a diesel engine with your own hands

Content

- Diesel engine glow plugs

- How does it work?

- Varieties of glow plugs

- Reasons for failure

- Glow plug malfunctioning symptoms

- How to check glow plugs?

- Visual inspection of glow plugs

- How to test the glow plug relay

- Diesel Glow Plug Quick Check

- Tips for Choosing Glow Plugs

- Instructions for self-replacement of glow plugs

- Related videos

- Questions and answers:

An important part of an internal combustion engine is the spark plug. And many motorists do not know what to do if there are problems with this part. What needs to be done to replace them and how to understand that the candle needs to be replaced?

Anyone who knows how spark plugs work will probably immediately notice if there are problems with this part. When the starter starts, but the engine still does not start, you need to unscrew the candle and check how it looks. If it is wet from gasoline, then most likely the spark plug or the electrical circuit itself is faulty. On the other hand, if the candle is dry, then it is necessary to find out why fuel is not entering the cylinder.

Determining whether a spark plug is faulty can be difficult because there are many signals for spark plug replacement or ignition failure. It is possible that the fault is not only in the spark plug, but also the ignition system or cable may be faulty. From practice we can say that modern spark plugs are of a high level of quality, so failures occur quite rarely.

Therefore, in newer cars, the spark plugs are changed prophylactically after driving the distance specified by the manufacturer. For example, in Felicia before 1997, which did not yet have a distributed (multipoint) injection, the candles were changed after 30 km.

There is a huge range of spark plugs on the market. There are hundreds of types of spark plugs and an equally wide range of prices - a spark plug can cost from 3 to 30 euros.

Spark plugs are under constant development, as are other vehicle components. Technologies and materials are being developed, and the shelf life has been increased from 30 km to about 000 km today. There are also spark plugs with replacement intervals up to 60 km. Since spark plugs are standardized products, which means that manufacturers must make spark plugs with specific characteristics, we recommend using spark plugs of the same type and manufacturer as your vehicle.

Diesel engine glow plugs

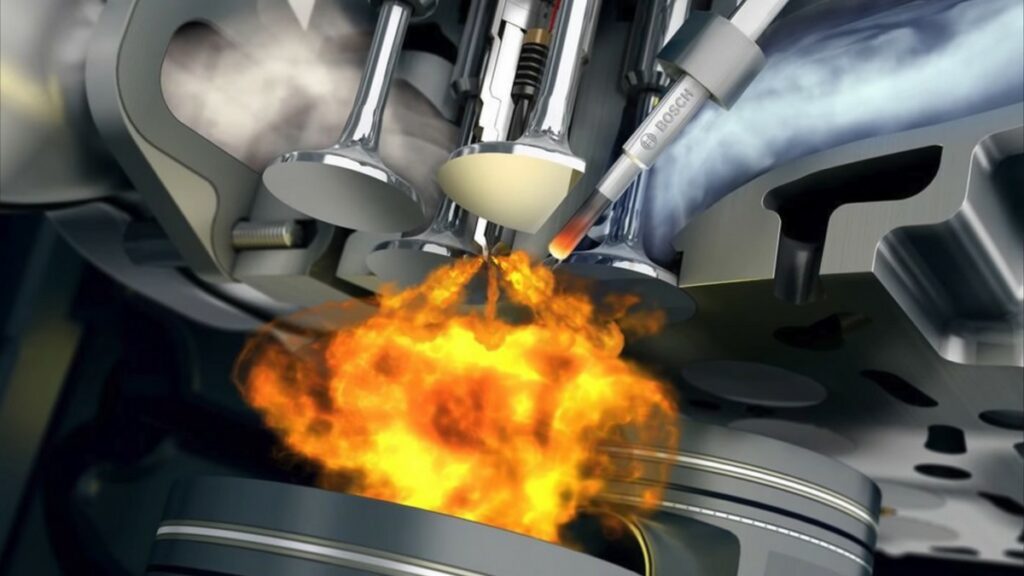

The glow plug in a diesel engine performs a different function than the spark plug in a gasoline engine. The main function of a spark plug is to ignite the mixture of air and fuel in the combustion chamber. At the moment, the glow plug plays a major role in preparing the engine for a cold start.

A diesel engine glow plug is a thin metal piece with a heating element at the end. Which is made of modern high temperature and oxidation resistant materials.

With newer diesel engines, the life of the glow plugs should be equal to that of the entire engine, so replacing the spark plugs is likely to cause certain problems. On older diesels, the glow plugs need to be replaced after approximately 90000 kilometers.

Unlike spark plugs, glow plugs are needed only at the moment of ignition, and not all the time the engine is running. Electricity is supplied to the heating element, which heats up to a high temperature. The incoming air is compressed, the injector nozzle directs fuel to the glow plug heating element when fuel is injected. The injected fuel mixes with air and this mixture begins to burn almost instantly, even if the engine is not warmed up.

How does it work?

Unlike a gasoline engine, a diesel engine operates on a different principle. In it, the mixture of fuel and air does not light up with the help of a spark plug. The reason is that the ignition of diesel fuel requires a temperature much higher than for gasoline (the air-fuel mixture ignites at a temperature of about 800 degrees). In order for diesel fuel to ignite, it is necessary to strongly heat the air entering the cylinder.

When the motor is warm, this is not a problem, and a strong compression is enough to warm up the air. For this reason, compression in diesel engines is much higher than in gasoline engines. In winter, especially during the onset of severe frosts, in a cold engine, this temperature is reached much longer due to one compression. You have to turn the starter longer, and in the case of high compression, more energy is required to start the motor.

To make it easier to start a cold engine, glow plugs have been developed. Their task is to warm the air in the cylinder to a temperature of about 75 degrees. As a result, the ignition temperature of the fuel is reached during the compression stroke.

Now consider the principle of operation of the glow plug itself. Inside it is installed heating and regulating coils. The first heats the body of the candle, and the second prevents it from overheating. After starting the engine, the glow plugs will continue to work until the temperature in the cooling system rises to +60 degrees.

Depending on the ambient temperature, this may take up to three minutes. After that, there is no need for candles, since the engine is warmed up and the ignition temperature of diesel fuel is already reached by compressing the air by the pistons.

The moment when the engine can be started is determined by the icon on the dashboard. While the glow plug indicator (spiral pattern) is on, the cylinders are warming up. When the icon goes out, you can crank the starter. In some car models, the engine starts more easily when the speedometer readings light up on the electronic scoreboard. Often this information on the dashboard appears after the spiral icon goes out.

Some modern cars are equipped with a system that does not include filament coils. This happens if the engine is already warm enough. There are also modifications of candles that turn off immediately after the starter is activated. They get so hot that after deactivation their residual heat is enough to ensure proper heating of the air in the cylinders until the engine warms up.

The whole process of air heating is controlled by an electronic control unit. It analyzes the temperature indicators of the motor itself and the coolant and, in accordance with this, sends signals to the thermal relay (it closes / opens the electrical circuit of all candles).

If the spiral on the dashboard does not go out after the set time or lights up again, this indicates a failure of the thermal relay. If it is not replaced, the glow plug will overheat and its heat pin will burn out.

Varieties of glow plugs

All glow plugs for diesel engines are divided into two types:

- Pin candle. Inside, such products are filled with magnesium oxide. This filler contains a spiral made of an alloy of iron, chromium and nickel. This is a refractory material, due to which the candle is able to heat up strongly and serve for a long time under such a heat load;

- Ceramic candle. Such a product is more reliable, because the ceramics from which the tip of the candle is made can withstand temperatures up to 1000 degrees.

For greater reliability, glow plugs can be coated with silicone nitrate.

Reasons for failure

A diesel engine glow plug can fail for two reasons:

- In case of malfunctions of the fuel system, for example, a failed thermal relay;

- The candle has worked out its resource.

Heater diagnostics should be carried out every 50-75 thousand kilometers. Some types of candles can be checked less often - approximately when reaching 100 thousand kilometers. If you need to replace one candle, then it is better to replace all the elements.

The following factors influence the duration of the candles:

- Nozzle clogging. In this case, the fuel injector can jet fuel instead of spraying it. Often a jet of cold diesel fuel hits the hot tip of the candle. Because of such sharp drops, the tip is quickly destroyed.

- Spark plug incorrectly installed.

- Over time, the thread of the candle sticks to the thread of the candle well, which makes it difficult to dismantle it. If you do not pre-treat the thread before removing the candle, then an attempt to apply force often leads to breakage of the product.

- A failed thermal relay will necessarily lead to overheating of the candle coil. Because of this, the product may deform or burn out the spiral itself.

- Breakdowns in the electronic control unit, due to which the operation mode of the candles will be incorrect.

Glow plug malfunctioning symptoms

Signs of bad spark plugs include:

- tip destruction;

- Deformation or swelling of the glow tube;

- The formation of a large layer of soot on the tip.

All these faults are detected by visual inspection of the heaters. But in order to pay attention to the condition of the candles, you need to take a closer look at the operation of the power unit. Among the problems:

- Difficult cold start. From the fifth or sixth time the car starts up (the cylinders heat up due to the strong compression of the air, but this takes much longer than when the air is heated by candles).

- Plentiful smoke from the exhaust pipe. Exhaust color is blue and white. The reason for this effect is that the mixture of air and fuel does not burn completely, but is removed along with the smoke.

- Unstable operation of a cold engine at idle. Often this is accompanied by shaking of the motor, as if it were troiting. The reason is that one candle does not work well or does not work at all. Because of this, the air-fuel mixture in that cylinder does not ignite or ignites with a delay.

Another reason for premature failure of glow plugs is in defective products.

How to check glow plugs?

There are 2 types of glow plugs:

- turn on almost every time the engine is started (typical of old cars)

- may not turn on at positive temperatures

To diagnose the pre-heating of a diesel engine, it is necessary to clarify at what temperature the combustion chamber is heated, as well as what type of candle is used a rod (a refractory metal spiral is used as a heating element) or ceramic (a ceramic powder is used in the heater)

Diagnostics of spark plugs in a diesel engine is carried out using:

- visual inspection

- battery (speed and quality of incandescence)

- tester (for a break in the heating winding or its resistance)

- light bulbs (for a break in the heating element)

- sparking (for old car models, as it can damage the ECU)

The simplest test is a test for conductivity; in a cold state, the candle should conduct current in the range of 0,6-4,0 ohms. If it is possible to access the candles, then any device is able to check for a break (the resistance will be infinite). If there is an induction (non-contact) ammeter, then you can do without removing the spark plugs from the engine. If all the candles failed at once, then it is also necessary to check the candle control relay and its circuits.

How to check glow plugs without unscrewing (on the engine)

Some motorists, not wanting to unscrew the candles so as not to damage them and speed up the procedure, try to check the performance of the heaters without removing them from the engine. The only thing that can be checked in this way is the integrity of the power wire (is there voltage on the candle or not).

To do this, you can use a light bulb or a tester in dialing mode. The design of some power units allows you to visually determine whether a single candle is working. To do this, the fuel injector is unscrewed and through its well it looks whether the candle glows with the ignition on or not.

How to test a glow plug with a light bulb

This method is not in all cases informative enough to establish the malfunction of a particular candle. To carry out the procedure, a small 12-volt light bulb and two wires are enough.

one wire connects to one contact of the light bulb and to the positive terminal of the battery. The second wire is connected to the other contact of the light bulb and is connected instead of the glow plug supply wire. If the candle is unscrewed from the well, its body should touch the negative terminal of the battery.

With a working candle (the heating coil is intact), the light should glow. But this method allows you to determine only the integrity of the heating coil. About how effectively it works, this method will not tell. Only indirectly this will be indicated by the dim light of a light bulb.

How to check glow plugs with a multimeter

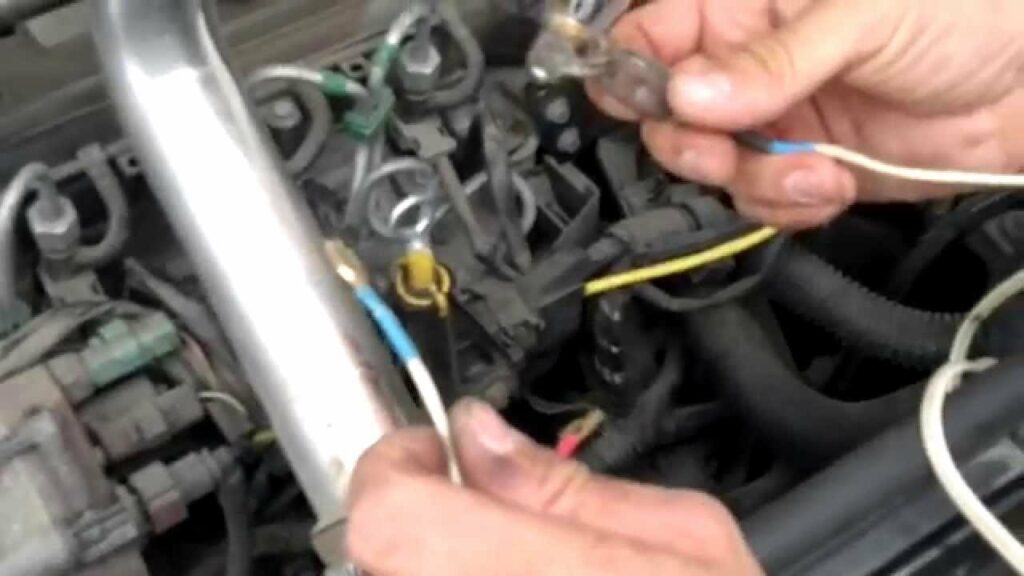

The multimeter is set to resistance measurement mode. The power wire is removed from the candle. This can be an individual wire or a common bus for all candles (in this case, the entire bus is removed).

The positive probe of the multimeter is connected to the terminal of the central electrode of the candle. The negative probe is connected to the candle body (on the side). If the heater is burned out, the multimeter needle will not deviate (or no numbers will appear on the display). In this case, the candle must be replaced.

A good element must have a certain resistance. Depending on the degree of heating of the spiral, this indicator will increase, and the current consumption will decrease. It is on this property that the electronic control unit in modern engines is oriented.

If the glow plugs are faulty, their resistance will be higher, so the amperage will decrease prematurely, and the ECU will turn off the plugs before the air in the cylinders is warm enough. On serviceable elements, the resistance indicator should be in the range of 0.7-1.8 ohms.

Another way to check candles with a multimeter is to measure the current consumed. To do this, a multimeter is connected in series (the ammeter mode is set), that is, between the central electrode of the candle and the supply wire.

Next, the motor starts. For the first few seconds, the multimeter will show the maximum current strength, since the resistance on the spiral is minimal. The more it warms up, the greater its resistance will be and the current consumption will drop. During the test, the readings of the consumed current should change smoothly, without jumps.

The check is performed on each candle without dismantling it from the motor. In order to be able to determine the faulty element, the multimeter readings on each candle should be recorded and then compared. If all elements are working, then the indicators should be as identical as possible.

Checking glow plugs with a battery

This method will show a clearer picture of the effectiveness of the candle. It allows you to visually determine how hot the candle is. The check should be carried out on the elements unscrewed from the engine. This is the key drawback of such diagnostics. The design of some motors does not allow easy dismantling of candles.

To test the heaters, you will need a solid wire. A cut of only 50 centimeters is enough. The candle is turned over and the central electrode is placed on the positive terminal of the battery. The wire connects the side of the candle body to the negative terminal. Since a working candle must be very hot, for safety's sake it must be held with pliers, and not with bare hands.

On a serviceable candle, the tip will glow by half and more. If only the tip of the heater turns red, then the candle does not effectively heat the air entering the cylinder. Therefore, the element must be replaced with a new one. If, after the last replacement of candles, the car has traveled about 50 thousand kilometers, then you need to change the entire set.

Visual inspection of glow plugs

As in the case of the condition of the spark plugs on a gasoline engine, some malfunctions of the engine itself, the fuel system, etc. can be determined from the condition of the glow plugs in a diesel unit.

But before you start checking the candles, you need to make sure that they are tightly screwed into the wells. Otherwise, poor contact with the motor housing may cause the heaters to work poorly.

Since the heating elements are quite fragile, when installing the candles, the correct tightening torque must be observed, which is indicated in the table:

| Thread diameter, mm: | Tightening torque, Nm: |

| 8 | 8-15 |

| 10 | 15-20 |

| 12 | 20-25 |

| 14 | 20-25 |

| 18 | 20-30 |

And this table shows the tightening torque of the contact nuts:

| Thread diameter, mm: | Tightening torque, Nm: |

| 4 (M4) | 0.8-1.5 |

| 5 (M5) | 3.0-4.0 |

The glow plug should be dismantled if the test with a multimeter indicated a malfunction.

Reflow tip

There are several reasons for this failure:

- Low compression or late ignition causes the tip to overheat;

- Early fuel injection;

- Damage to the pressure valve of the fuel system. In this case, the motor will run with an unnatural sound. To verify that the problem is in the pressure valve, the fuel line nut is unscrewed with the engine running. From under it will not go fuel, but foam.

- Violation of fuel atomization due to clogging of the nozzle socket. The performance of fuel injectors is checked on a special stand, which allows you to see how the torch is formed in the cylinder.

spark plug defects

If problems with candles appeared with a small car mileage, then their defects in the form of swelling of the body, traces of overheating or cracks can be provoked by:

- Failure of the thermal relay. Due to the fact that it does not turn off the candle for a long time, it overheats (the tip will crack or even crumble).

- Increased voltage in the on-board system of the car (the tip will swell). This can happen if a 24-volt plug is inserted into the 12-volt network by mistake. Also, a similar problem can be triggered by improper operation of the generator.

- Incorrect fuel injection (there will be a large layer of soot on the candle). The reason for this may be a clogged nozzle, due to which the fuel is not sprayed, but spurts directly onto the tip of the candle. Also, the problem may be in the incorrect operation of the control unit (errors in the moment or spray mode).

How to test the glow plug relay

It is necessary to pay attention to the performance of the thermal relay, even if the installation of new candles did not help eliminate the difficult start of a cold engine. But before changing expensive elements of the air heating system, you should check the condition of the fuses - they can simply blow out.

A thermal relay in a diesel engine is needed to turn on / off the heaters. When the driver turns the key in the ignition switch to turn on the vehicle's on-board system, a distinct click will be heard. This means that the thermal relay has worked - it turned on the candles to warm up the pre-chamber of the cylinder head.

If the click was not heard, then the relay did not work. But this does not always mean that the device is faulty. The problem may be in the errors of the control unit, in a rush of wiring, failure of the temperature sensors of the cooling system (all this depends on the type of power unit and on-board auto system).

If, when the key is turned in the ignition switch, the spiral icon on the tidy does not light up, then this is the first sign of the failure of one of the listed sensors or a fuse.

To check the performance of a thermal relay, you need to be able to correctly read the diagram drawn on the device case, since each relay may be different. The diagram indicates the type of contacts (control and winding contacts). A voltage of 12 volts is applied to the relay, and the circuit between the control and winding contact is closed using a test lamp. If the relay is OK, the light will turn on. Otherwise, the coil burned out (most often this is the problem).

Diesel Glow Plug Quick Check

The video, using the Citroen Berlingo (Peugeot Partner) as an example, shows how you can quickly find a broken spark plug:

This method also only allows you to establish whether there is a break in the filament spiral. About how efficiently the heating works, this method does not allow you to establish. It is also worth considering that on modern diesel engines equipped with an electronic control unit, this method should not be used, because the computer can be disabled.

Tips for Choosing Glow Plugs

Considering that the same car model can be equipped with different types of power units, glow plugs in such diesel engines may differ. It should also be remembered that with the identity of many related models from different manufacturers, heaters may differ in size.

To avoid incorrect installation or rapid damage to glow plugs, it is necessary to select such parts as the manufacturer recommends. The best way to find the right option is to look for candles by VIN number. So you can accurately choose a candle that will not only be suitable for installation, but will also be compatible with the control unit and the vehicle's electrical system.

When choosing new glow plugs, you need to consider them:

- Dimensions;

- Type of connection to the electrical system;

- Speed and duration of work;

- Heating tip geometry.

Instructions for self-replacement of glow plugs

To replace glow plugs yourself, you will need:

- Socket and wrench;

- Ratchet for head;

- Pliers;

- Screwdriver;

- Gloves;

- High temperature and graphite grease.

The procedure is as follows:

- The plastic casing is removed from the motor (if there is a similar element above the motor);

- The battery is disconnected;

- The supply wire is disconnected (it is screwed with a nut onto the central electrode of the candle);

- Clean the motor housing near the spark plug wells so that debris does not get into the cylinders during the dismantling or installation of new spark plugs;

- Old candles are carefully unscrewed;

- Clean the thread if it is dirty. To prevent debris from entering the cylinder, you can use a car vacuum cleaner and a stiff brush (not for metal);

- Lubrication is useful to facilitate the installation of the candle in the well so that the thread does not break if there is rust in the well.

If it became necessary to replace one or two candles, then the whole set still needs to be changed. So it will not be necessary to carry out dismantling work when the next old candle fails. You should also eliminate the cause of premature failure of the candle.

Related videos

In conclusion, a short video about self-replacing diesel engine glow plugs:

Watch this video on YouTube

Questions and answers:

How to check candles without removing them? This will require a voltmeter (mode on a multimeter) or a 12-volt light bulb. But this is only a primary check. It is impossible to completely check without unscrewing it from the motor.

How to check if the glow plugs are receiving power? The lead of the 12-volt lamp is connected to the battery (terminal +), and the second contact is connected directly to the plug of the plug (the positive lead of the plug must be disconnected).

How do you know if glow plugs are not working? Heavy smoke appears on cold start. While the motor is at operating temperature, it makes a lot of noise. A cold internal combustion engine is unstable. Reduced power or increased fuel consumption.