Working principle and working principle of the Audi Quattro

Content

The famous 4X4 Quattro machine ... Who does not know this name, so famous among lovers of beautiful cars? However, if this name has almost become a legend, you need to take a closer look at what it includes, because there is sometimes a nice difference between Quattro and Quattro!

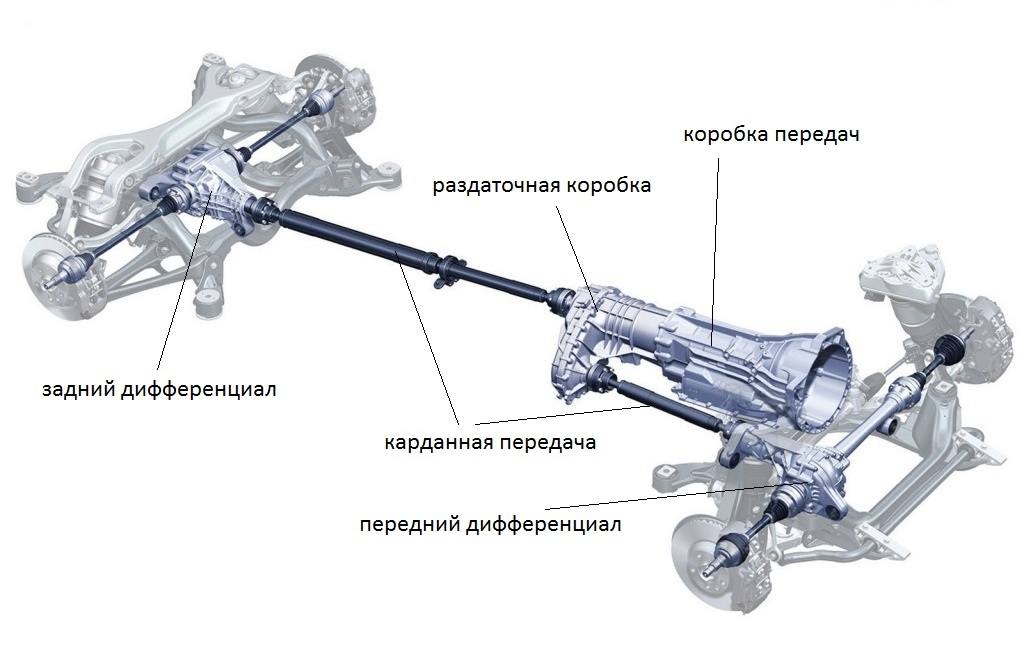

So we're going to see the various Quattro systems that exist on Volkswagen Group vehicles, because yes, some Volkswagen also benefit from them. Thus, there are three main systems: one for the front longitudinal engine, the other for the rear longitudinal engines (rarely, R8, Gallardo, Huracan ...) and the last one for the most common cars (transverse engine).

How the different types of Quattro work

Now let's take a closer look at the architecture and operation of the various types of Quattro.

Quattro TORSEN for longitudinal engine (1987-2010)

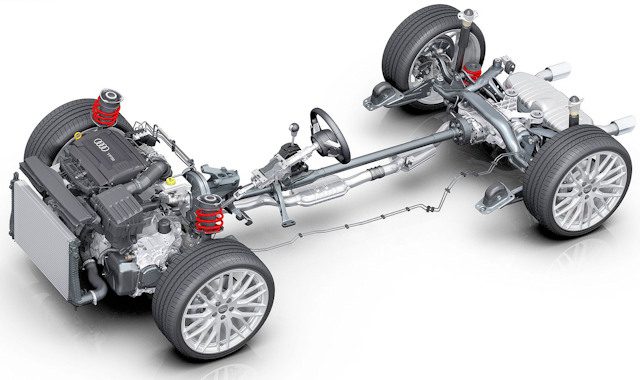

A6 with longitudinal motor

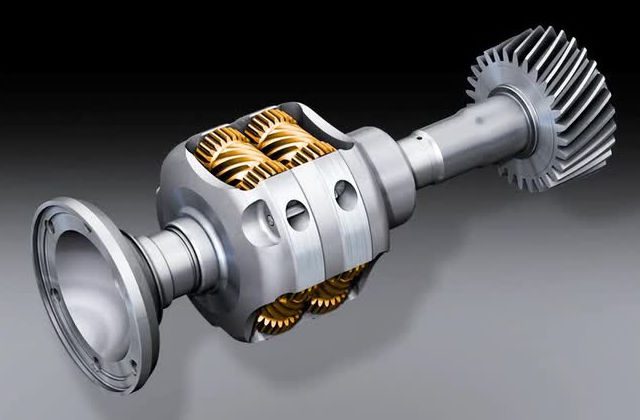

Torsen symmetrically limits the speed difference between the two axles (if it is limited to 70% then we may have a torque distribution of 30% / 70% or 70% / 30%).

trade: passive / permanent

Distribution couple Avant / rear : 50% - 50%

(with equal traction between the front and rear axle)

Modulation : from 33% / 67% (or therefore 67% / 33%) to 20% / 80% (or 80% / 20%) depending on the Torsen version (depending on the shape of the teeth and gears Torsen studied)

Challenge: Limit sliding between the front and rear so that you can get out of the slippery areas.

Here's a bit of the Torsen interior, its mechanism prevents one of the two sides from turning without moving the other, unlike a conventional differential. Here, the motor rotates the entire differential housing (highlighted in gray), which has two shafts (front and rear wheels) connected to each other by gears to limit the speed difference between them (the famous limited slip).

This is a transfer constant which therefore transmits the torque on the axles

forward and backward stable

.

The torque starts from the engine, is transmitted to the box, and then it all goes to the first Torsen limited slip differential (Torsen for Torthat Sept.sing). From this differential, we go back and forth in a 50/50 split. It is impossible to completely disconnect the rear or front axle here, the four wheels always receive torque, even a small one. The Torsen differential will be (I cannot confirm at the moment) slightly different from the line of luxury SUVs (slightly more suitable for crossing): Touareg, Q7, Cayenne.

Both the front and rear axles have a standard differential (no slip limit) that distributes torque between the left and right wheels. But there are slightly more advanced versions of the Quattro designed for sportier versions.

Finally, torque vectoring can only be applied here by ESP playing on the brakes, so it is much less developed than the torque vectoring of the Quattro Sport rear differential.

Quattro CROWN GEAR (pinion / flat gear) for longitudinal motor (2010 -…)

Q7 with longitudinal motor

This version (since 2010) uses a different type of transfer case. This allows motor skills to be modulated. asymmetric between different axles due to the more or less important blocking of the viscous clutch.

In any case, this is a permanent transmission that will constantly transmit torque to the front and rear (although of course the torque modulation can be changed between the axles depending on the clutch, but there will always be a pair that will occur on each of them) ...

trade: passive / permanent

Distribution couple Avant / rear : 60% - 40%

(with equal traction between the front and rear axle)

Modulation : from 15% / 85% to 70% / 30% depending on the difference in grip between the front and rear axles. This is asymmetrical, as you can see from the level of possible distributions between the front and back.

Objective: Flirt with BMW buyers by explaining that you can

в

85% power in the rear (in BMW we were always 100%)

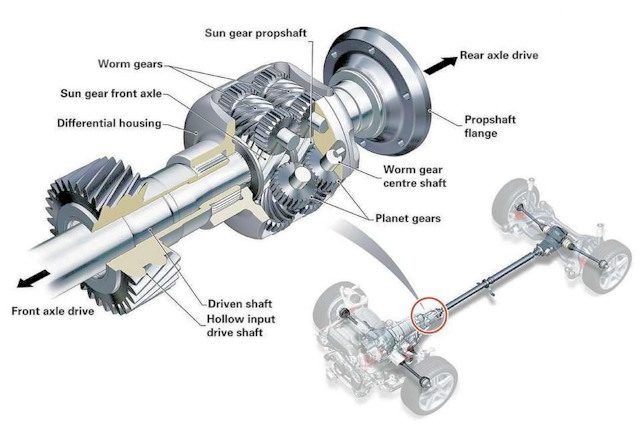

The bell (housing) of the differential (the black rectangle that surrounds everything) is connected to a center axle equipped with planetary gears ("little gray sprockets" that connect the front and rear shafts, thus leading to the front and rear axles).

The green shaft leading to the rear axle can be coupled to the bell through the multi-plate clutches visible in the orange area. This is a viscometer (it allows you to have limited slip, otherwise a basic diff which does not prevent slippage): the connection between the green and gray clutches occurs if there is a difference in speed (this is the principle of a viscous clutch, the oil in the cabin expands when heated, which allows the clutches to join together because the silicone expands when hot, and the speed difference between the clutches causes agitation that heats up the silicone oil). This causes the differential bell to couple to the rear axle shaft if there is a difference in speed between the two.

The initial distribution is 60 (back) / 40 (front) because the center axle gears (purple) do not touch the rims (blue and green) in the same place (more inward for blue = 40). % or more outward for green = 60%). The torque is different from the base because there is a different leverage effect.

All power goes through the black shaft that crosses the blue shaft (leading to the front axle). This rotates the axle connected to the differential housing, and therefore the sun gears. These sun gears are connected to flat gears (blue and green "flywheels").

If the speed between the rear shaft and the differential housing thickens, silicone: the couplings are glued to each other, and as a result, the motor shaft will be directly connected to the rear axle (through a bell that is connected to the engine, but it will also refer to the rear axle if the viscous coupling engages In this case, we have 85% for the rear axle and 15% for the front axle (situation = loss of traction on the front axle).

Theory above and practice below.

Differential Crown Gear - Audi Emotion Club AUDIclopedia

Quattro Ultra (2016 - ...)

trade: active / not permanent

Distribution couple Avant / rear : 100% - 0%

(with equal traction between the front and rear axle)

Modulation : from 100% / 0% to 50% / 50%

Target ; Offer all-wheel drive that limits consumption to the maximum, even if it means sacrificing the nobility of past devices.

Traction mode, most of the time (just like Haldex), the main goal is to reduce consumption and, more importantly, be flawless in any terrain.

This version is the most recent at the time of this writing, we are talking about replacing the Crow wheel with a disconnectable device. The latter can indeed decouple the rear shaft to be able to switch to tractive effort, and therefore it is no longer a permanent transmission ... So the system is a lot like Haldex, but Audi is doing everything to make us think about it as little as possible. as much as possible (a brand that is well aware of Haldex's much lower reputation compared to Torsen and Crown Gear). There are also two clutches on either side of the rear axle to disengage the center shaft, as rotating it (even in a vacuum) requires energy. The big difference is that the Torsen / Crown Gear is self-care and very durable, whereas this system needs to be controlled by a computer connected to a variety of sensors. Therefore, it is potentially less reliable, but also less durable as the discs can get hot (it is also limited to 500 Nm of torque, unlike the classic Quattro with Torsen).

This device is surprisingly close to the Porsche system available on the Macan, even if the brands do everything to muddy the waters and pretend that they have nothing in common (in fact, this is not true, the material for many elements is the same, and often even ZF. which designs everything) ... Moreover, it is almost the same principle, except that the Porsche differential allows the use of traction or traction (traction only or 4X4 on a Quattro Ultra with a switchable multi-disc differential).

In its way of working, we can say that this is the complete opposite of XDrive, as the BMW device continuously connects the engine to the rear and, if necessary, attaches the front axle to the transmission. Here the front axle is always connected and, if necessary, the rear axle is connected to the transmission chain and absorbs 50% of the torque.

When a loss of traction is detected on the rear axle, the rear axle shaft is connected to the transmission chain.

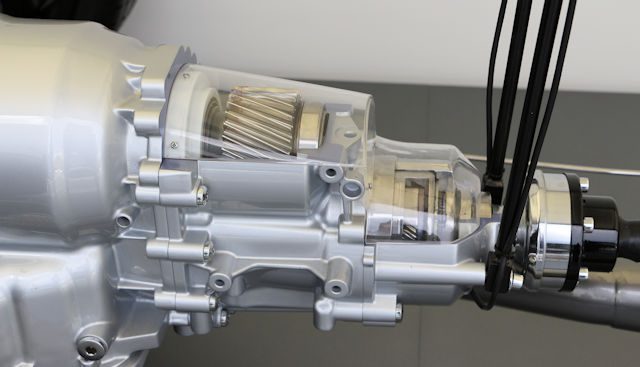

Here is the famous switchable "differential" (red - clutch)? Unfortunately, it is limited to 500 Nm of torque, which proves its less drag compared to the good old Quattro with Torsen.

2018 Audi Q5 quattro Ultra HOW THE NEW CENTRAL LOCK WORK - Audi [Old Torsen] DIFFERENTIAL AWD

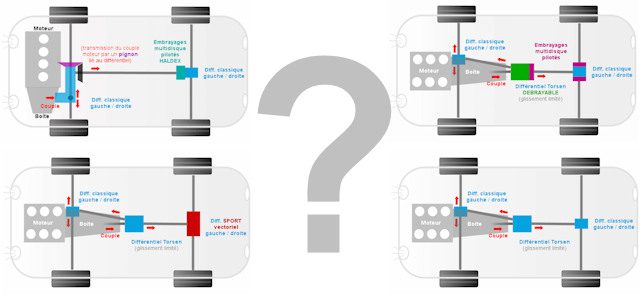

Quattro for transverse motor

Q3 transverse motor

trade: active / not permanent

Distribution couple Avant / rear : 100% - 0%(with equal traction between the front and rear axle)

Modulation : from 100% / 0% to 50% / 50%

Objective: To be able to offer four-wheel drive on the small vehicles of the group thanks to the equipment manufacturer Haldex / Borgwarner.

Here is an Audi TT, but it is the same for everyone.

Haldex 5. Generation - How it works

Everything is completely different here, since we are dealing with a completely different architecture. The transverse arrangement optimizes the available space in the vehicle at the expense of the vehicle's balance (remembering that here we are forgetting about large blocks and large, very robust transmissions!).

In short, everything, as always, starts with the internal combustion engine / gearbox. At the output, we have a differential that fully rotates and drives the central shaft of the transmission through the gear indicated in the diagram in purple. Thus, the inside of the front differential is split into two parts for the left and right wheels.

At the end of the transmission shaft connecting the front and rear is the famous Haldex, so controversial to connoisseurs. Indeed, everyone (or rather, people who are keen on cars) know the Haldex / Torsen warrior well ...

In fact, Torsen and Haldex don't care that one is a limited-slip differential and the other is an electronically actuated multi-plate clutch system (hydroelectric), which therefore tries to play the role of a differential.

In this configuration, the car cannot get more than 50% of the rear axle torque and this is easy to understand by looking at the image above.

In addition, the work is mainly done in traction mode, and the rear can be completely shut off without receiving any more torque: Haldex is shut down and there is no longer a connection between the center shaft and the rear differential.

Haldex / Torsen difference?

The differences between them are significant. Torsen is a passive differential that works mechanically and autonomously. It provides constant torque on both axles (torque varies but force is always transferred to all wheels). Haldex needs a computer and actuators to operate, and its main task is to act in response.

While the Torsen is running all the time, Haldex waits for a loss of traction before engaging, causing a small amount of downtime that reduces its efficiency.

In addition, unlike the Torsen, this system heats up much faster due to the friction of the discs: therefore, in theory, it is less durable.

Quattro Sport / Vector graphics / Torque vector

The challenge: to improve the car's cornering performance and limit the natural understeer caused by Audi (whose engine is too far forward).

There's either a Torsen or Crown Gear differential here.

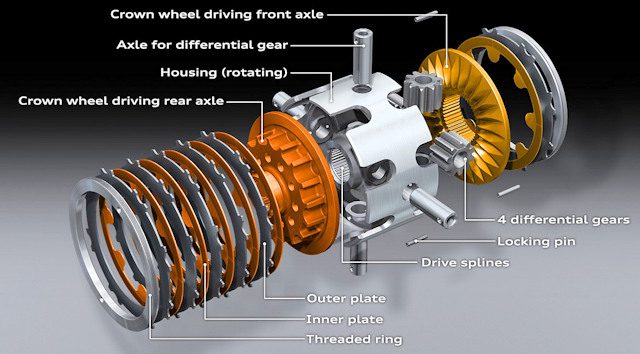

The Quattro Sport consists of a much more refined sports differential at the rear. Indeed, the latter allows us to propose the famous vector pair (which we usually know in English: Torque Vectoring. Click here to learn more about the operation).

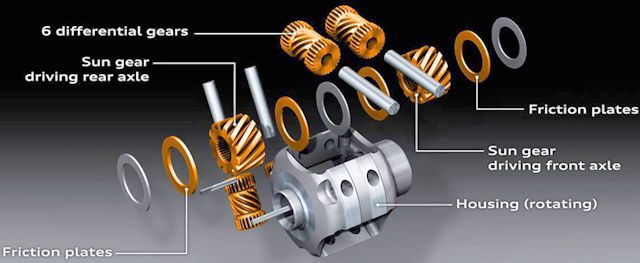

The latter consists of multi-plate clutches and planetary gears arranged in a spiral.

Click here to find out more

Quattro evolution: synthesis

Longitudinal Quattro evolution: en bref

Except for transverse or rear-engined vehicles, the Quattro system is now in its sixth generation. Therefore, it consists in revitalizing all the wheels of the car with the help of transmission shafts and numerous differentials.

The first generation appeared at the very beginning of the 80s (exactly 81), had 3 differentials: one in the classic front, two in the center and back, which could be locked (without sliding or modulation, it is locked).

This was in the second generation when the center differential was embodied by the Torsen, a limited slip differential and no longer the only differential lock. This then allows the front / rear power to be modulated between 25% / 75% or vice versa (75% / 25%) instead of blocking 50/50 as in the first generation.

Then Torsen was also invited to the rear axle from the third generation, knowing that the latter was only used on the 8 Audi V1988 (this is the future A8, but it hasn't received a name yet).

The fourth generation is slightly more economical (not just supplying luxury limousines like the Audi V8) with a classic rear differential (which can be electronically locked, hence brakes via ESP).

The system has thus evolved, retaining the same philosophy to this day by improving the central Torsen's ability to constantly vary the transmitted torque between the front and rear axles (now up to 85% mechanically on the axle and even 100% thanks to the ESP acting on the brakes. making it almost as enjoyable to operate the system as it would be with a clean powerplant).

Then came a sports differential (mounted on the axle, it is not a front / rear differential, but a left / right one) on the optional rear axle or on some sports cars (S5, etc.). This is a famous torque vectoring technology that is quite popular among all premium manufacturers, it is not only related to the Quattro.

Then came the Quattro Ultra (we always talk about longitudinally engineered cars), designed to reduce fuel consumption. No more permanent transmission, it can be completely separated (rear axle obviously) to save energy.

So, if we sum it up (knowing that the demarcation of dates is not always obvious, because the period may include cars with several generations of Quattro. Example: in 1995, Audi was sold with Quattro 2, 3 or 4 ...):

- Generation 1 Quattro: 1981 - 1987

- Quattro 2nd generation Torsen: 1987 - 1997

- Generation 3 Torsen Quattro: 1988 - 1994 (only on A8 ancestor: Audi V8)

- Quattro 4nd generation Torsen: 1994 - 2005

- Quattro 5nd generation Torsen: 2005 - 2010

- Quattro 6th generation Crown Gear: since 2011

- Quattro generation 7 Ultra (parallel to generation 6): from 2016

Evolution of the Quattro Transversal: in brief

The Audi / Volkswagen group also sells many popular cross-engine vehicles (A3, TT, Golf, Tiguan, Touran, etc.), for these models it was necessary to offer four-wheel drive.

And this is where the Quattro is being offered for Volkswagen, Seat and Skoda, because it is no longer the real Quattro that purists adore.

If the device was rather slow in responding to its start (activation of the rear axle), then since then it has advanced significantly with today's fifth generation. However, it is logically less complex and calibrated than the Quattro for a longitudinal engine designed for the most luxurious cars. This device was invented by the Swedes, not by Audi.

The Porsche connection?

Even if Porsche does its best to suppress it, Quattro drivetrains are very much a concession, if not an identity. Speaking of Cayenne, we can definitely talk about Quattro. The Macan simply replaced the center Haldex with a system almost identical to the Quattro Ultra (removable Torsen). The difference here is that we can send 100% forward or backward, with the Quattro ultra limited to converting the car into traction. It is otherwise identical to the optional Vectoring rear differential and PDK gearbox, which is actually an S-Tronic (plus supplied by ZF). But shhh, I'll be scolded if this gets out...