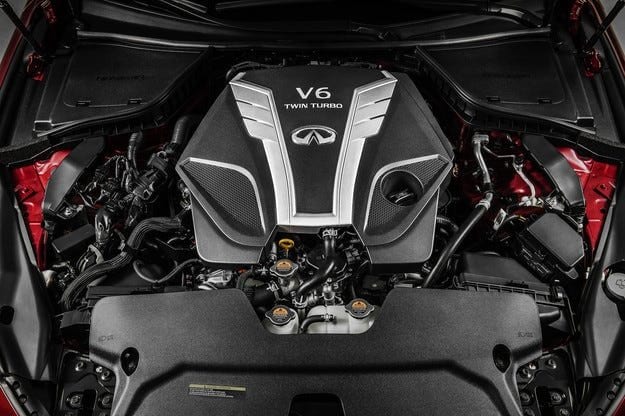

Test Drive Introducing Most Advanced V6 Engine Ever Made by Infiniti

This twin-charge motor is from a new family of devices labeled "VR".

New compact and lightweight 3-liter twin-turbo V6 unit. Infiniti is the most advanced V6 engine ever produced by the company. Striking the perfect balance between handling, efficiency and power.

This dual-supercharged engine belongs to Infiniti's new "VR" engine family. Comes from a long tradition and heritage of the brand in the production of V6 engines. It is designed to give the driver more power and to offer more power, torque and increased levels of performance compared to all of the company's comparable predecessors so far.

The weight of the engine has been reduced, as well as its own size, in order to partially lighten and make the cylinder block more compact. The result is higher mechanical efficiency, while at the same time a number of new developments and additions provide more power.

Select Infiniti models, including the improved Q50, will be powered by an all-new 3 6-litre twin-turbo V2016 engine from year 300. With a choice between two power levels - 400 or XNUMX hp. Both engines use the same technology and offer the same genuine sense of potential and instantaneous power delivery.

The most advanced V6 engine ever produced by Infiniti

The all-new 3-liter V6 VR twin-turbo engine delivers a complete blend of handling, efficiency and power. The "VR" engines will be used in new Infiniti models, models designed to meet the needs of all Infiniti markets around the world, signaling the brand's growing global presence.

With a rich history of V6 engine manufacturing, Infiniti has been able to draw on its extensive six-cylinder experience to create the new 3-liter twin-turbo V6 engine. The VQ V6 family of units, which are the predecessors of the VR model, have proven themselves well and since 1994 have received various awards in various engine series.

For fourteen years from 1995 to 2008, the Infiniti VQ was ranked among the "10 Best Engines in the World", an unrivaled achievement.

Best-in-class new technologies for power and efficiency

The all-new 3-liter twin-turbo V6 engine is designed to provide optimum power and torque for an engine of its size. Together with the tray, fuel consumption has improved. The version with the higher generating capacity has 400 hp. (298 kW) at 6400 rpm and 475 Nm in the range from 1600 to 5200 rpm.

So far, the 300 hp version. equipped with one water pump and a 400hp pump. uses two for more efficient temperature control during operation. In addition to the more powerful version, there is an optical turbine speed sensor that gives a 30% increase in power from the turbine system, allowing the blades to spin faster.

These figures were achieved simultaneously with a 6,7% improvement in fuel consumption, which is the best power-to-efficiency ratio in its class for a 400 hp unit.

This efficiency aimed at saving energy has been achieved through a package of new developments. Advanced time control provides increased availability by allowing quick response to driver commands.

A new electric motor is installed in the valve timing system to improve the speed of the accelerator pedal response. This has a positive effect not only on electricity, but also on savings. Because the engine can run more efficiently by more direct in-cylinder combustion control.

Power is increased by a modern twin-turbo system. It provides smooth and immediate response when accelerating while improving efficiency. Optimized Turbine Blade Design Optimized turbine blade designs help the engine generate overall power, while higher turbine speeds provide immediate system response.

In addition, the V6 engine has a new turbine speed sensor that allows the twin-turbo system to operate at 220 rpm. – at rest and 000 rpm. in a transitional state. More than ever before for the Infiniti V240. With more power for higher rpm, the twin turbos push the more powerful version of the engine for more power and torque. Turbine speed sensor in 000 hp version allows you to increase power up to 6%.

Infiniti engineers have developed a water-cooled intercooler to further improve traction and efficiency. The system rapidly cools the air entering through the turbines, removing the turbo port and providing instantaneous acceleration. Another result is a more compact cooling system. This means a shorter airflow path that enters the turbocharger and allows the engine to respond faster.

The new electronic exhaust valve drive allows for more precise control of the clean gas flow outside the turbine. This limits the amount of exhaust gases that pass through the unit to improve overall engine performance.

Less weight, better mechanical efficiency, more pleasant handling.

The unit of the 3-liter twin-turbo V6 weighs 194,8 kg. This is 14,1 kg less than its predecessor. Its forced filling system and modern interior as separate components add only 25,8 kg, which is 220 kg.

The all-new unit is 19% (0,7 liters) less power than previous Infiniti V6 engines. It continues the legacy of introducing new solutions and technologies. Just like the first Infiniti engines, they have always been respected for their lightweight aluminum construction and low mechanical friction, making them smooth, resilient and responsive. The three-liter twin-turbo V3 engine follows its performance-oriented predecessors with a more compact and lighter design that places a premium on power.

Leading new features for weight reduction is the use of non-contact surface coating on the cylinder block and an integrated exhaust manifold for the cylinder heads.

This not only makes the engine lighter, but also helps cool as heat is removed from its physical structure. This stimulates faster heating.

The lighter weight of the entire engine improves efficiency. With less inertia than its lightweight aluminum components, it increases productivity while improving handling and overall potential.

Infiniti engineers have mastered a range of innovations and technologies to integrate into the new V6 for a more enjoyable driving experience. The leader among them is the new direct fuel injection system. The DIG system injects fuel more accurately into the combustion chamber, delivering the exact amount required for smooth acceleration, depending on the pedal position and engine speed. This system makes the new V6 the most efficient and fuel efficient engine of its type that Infiniti has ever produced. Equivalent to a 6,7% increase in fuel economy.

Modern synchronous shaft control allows more precise control of the mixture of fuel and air in the combustion chamber. This helps the engine run more efficiently and improves fuel economy under all circumstances.

Infiniti introduces a new cylinder coating process to improve mechanical efficiency. New friction reduction technology allows pistons to move more freely in the cylinders by reducing mechanical friction by 40% compared to previous V6 engines. The process of mirror cladding of holes consists in processing the cylinder walls with thermal blowing onto the casing, after which this layer is strengthened. Smooth mirrored cylinder walls reduce piston friction and increase power. The mirroring process of the cylindrical holes is reduced by 1,7 kg compared to older generation V6 engines.

This is due to the improved properties that the spray system imparts to lighter materials.

One of the most significant advantages of Infiniti's 3-liter twin-turbo V6 engine is the new integrated exhaust manifold. Built into the cylinder head, allowing engineers to place the catalyst at the exhaust point. This allows the catalyst to heat up almost immediately. Twice as fast as the previous Infiniti V6 engine. This reduces harmful emissions from cold ignition.

Moving the catalyst reduces weight, making the engine more compact than before. This design removes 5,3 kg of its weight.

The new aluminum cylinder block is designed in the form of a "square" with straight bores and cylinder stroke (86.0 x 86.0 mm). The result is a 3-litre twin-turbo V6 engine that combines low mechanical friction with high responsiveness. Power and torque are achieved over a wide range of top average speeds, which are most commonly used in daily driving. The result is what Infiniti engineers do

consider it the perfect balance of handling, efficiency and performance.

The new V6 engine will go into production in 2016.

The new 3-liter twin-turbo V6 engine is due to enter service in 2016 and will be produced in Iwaki, Fukoshima, Japan.

Home " Articles " Blanks » Introducing the most advanced V6 engine ever produced by Infiniti