GDI engines: pros and cons of GDI engines

Content

- What is auto GDI injection system

- The device and principle of operation of the GDI system

- Differences (varieties) of GDI engines. Car brands where GDI is used

- Features of system operation

- Pros and cons of use

- Preventing malfunctions of GDI motors

- Should you buy cars with GDI engines?

- History of GDI and PFI

- Frequently Asked Questions about GDI Engines

- Is the Gdi engine good?

- How long will a Gdi engine last?

- What is the problem with Gdi engines?

- Do Gdi engines need cleaning?

- Do Gdi engines burn oil?

- How long do Gdi engines last?

- Are Gdi engines noisy?

- What is better Mpi or Gdi?

- Is the Gdi engine reliable?

- Do all Gdi engines need cleaning?

- Why do Gdi engines burn oil?

- Is the Gdi engine good?

- What are the disadvantages of Gdi?

- How often should a Gdi engine be cleaned?

- How to keep a Gdi engine clean?

- How often do you need to change the oil in a Gdi engine?

- What oil is recommended for a Gdi engine?

- Questions and answers:

To improve the efficiency of powertrains, manufacturers have developed new fuel injection systems. One of the most innovative is the gdi injection. What is it, what are its advantages and are there any disadvantages?

What is auto GDI injection system

This abbreviation is worn by motors of some companies, for example, KIA or Mitsubishi. Other brands call the system 4D (for Japanese cars Toyota), the famous Ford Ecoboost with its incredibly low consumption, FSI for representatives concern WAG.

The car, on the engine of which one of these labels will be installed, will be equipped with direct injection. This technology is available to gasoline units, because diesel has a direct supply of fuel to the cylinders by default. It won't work on another principle.

The direct injection engine will have fuel injectors that are installed in the same way as the spark plugs in the cylinder head. Like a diesel engine, gdi systems are equipped with high-pressure fuel pumps, which allow to overcome the compression force in the cylinder (gasoline in this case is supplied to the already compressed air, in the middle of the compression stroke or during air intake).

The device and principle of operation of the GDI system

Although the principle of operation of systems from different manufacturers remains the same, they differ from each other. The main differences are in the pressure that the fuel pump creates, the location of key elements and their shape.

Design features of GDI engines

The engine with direct fuel supply will be equipped with a system, the device of which will include the following elements:

- High-pressure fuel pump (injection pump). Gasoline should not only enter the chamber, but it should be sprayed into it. For this reason, its pressure must be high;

- An additional booster pump, thanks to which fuel is supplied to the fuel pump reservoir;

- A sensor that records the force of the pressure generated by the electric pump;

- A nozzle capable of spraying gasoline under high pressure. Its design includes a special spray that forms the required torch shape, which is formed as a result of fuel combustion. Also, this part provides high-quality mixture formation directly in the chamber itself;

- The pistons in such a motor will have a special shape, which depends on the type of torch. Each manufacturer develops its own design;

- The intake manifold ports are also specially designed. It creates a vortex that directs the mixture to the electrode area spark plug;

- High pressure sensor. It is installed in the fuel rail. This element helps the control unit to control different modes of operation of the power plant;

- System pressure regulator. More details about its structure and principle of operation are described here.

Operating modes of the direct injection system

The gdi motors can operate in three different modes:

- Economy mode - fuel intake when the piston performs a compression stroke. In this case, the combustible material is depleted. At the intake stroke, the chamber is filled with air, the valve closes, the volume is compressed, and at the end of the process, gasoline is sprayed under pressure. Due to the formed vortex and the shape of the piston crown, the BTC mixes well. The torch itself turns out to be as compact as possible. The advantage of this scheme is that the fuel does not fall on the cylinder walls, which reduces the thermal load. This process is activated when the crankshaft rotates at low revs.

- High-speed mode - gasoline injection in this process will occur when air is supplied to the cylinder. The combustion of such a mixture will be in the form of a conical torch.

- Sharp acceleration. Gasoline is injected in two stages - partly at the intake, partly at compression. The first process will lead to the formation of a lean mixture. When the BTC finishes compressing, the rest of the portion is injected. The result of this mode is the elimination of possible detonation, which may appear when the unit is very hot.

Differences (varieties) of GDI engines. Car brands where GDI is used

It is not hard to predict that other leading car manufacturers will be developing a system that works according to the GDI scheme. The reason for this is the tightening of environmental standards, tough competition from electric transport (most motorists tend to give preference to those cars that consume the minimum amount of fuel).

It is difficult to create a complete list of car brands in which such a motor can be found. It is much easier to say which brands have not yet decided to reconfigure their production lines for the manufacture of this type of internal combustion engine. Most of the latest generation machines are likely to be equipped with these units, as they show sufficient economy along with an increase in efficiency.

Old cars definitely cannot be equipped with this system, because the electronic control unit must have special software. All processes occurring during the distribution of fuel to the cylinders are electronically controlled based on data from a variety of sensors.

Features of system operation

Any innovative development will be more demanding on the quality of consumables, since the electronics immediately respond to the slightest changes in the operation of the motor. This is related to the mandatory requirement to use only high-quality gasoline. Which brand should be used in a particular case will be indicated by the manufacturer.

Most often, the fuel should not have an octane number lower than 95. More information on how to check gasoline for compliance with the brand can be found in separate review... Moreover, you cannot take ordinary gasoline and increase this indicator with the help of additives.

The motor will immediately react to this with some kind of breakdown. The only exception will be materials that are recommended by the car manufacturer. The most common failure of a GDI internal combustion engine is an injector failure.

Another requirement of the creators of units in this category is high-quality oil. These guidelines are also mentioned in the user guide. Read about how to choose the right lubricant for your iron horse. here.

Pros and cons of use

By reducing the process of fuel supply and the formation of the mixture, the engine receives a decent increase in power (in comparison with other analogs, this figure can increase up to 15 percent). The main goal of manufacturers of such units is to reduce environmental pollution (most often not from worries about the atmosphere, but because of the requirements of environmental standards).

This is achieved by reducing the amount of fuel entering the chamber. The positive effect associated with improving the environmental friendliness of transport is a reduction in fueling costs. In some cases, consumption is reduced by a quarter.

As for the negative aspects, the main disadvantage of such a motor is its cost. Moreover, the car owner will have to pay a decent amount not only to become the owner of such a unit. The driver will have to spend decent money on engine maintenance.

Other disadvantages of gdi engines include:

- Mandatory presence of a catalyst (why is it needed, read here). In urban conditions, the engine often goes into economy mode, which is why the exhaust gases must be neutralized. For this reason, it is not possible to install a flame arrester or blende instead of the catalyst (the machine will definitely not be able to fit into the framework of eco-standards);

- To service the internal combustion engine, you will need to purchase a higher quality, and at the same time more expensive, oil. The fuel for the engine must also be of higher quality. Most often, the manufacturer indicates gasoline, the octane number of which corresponds to 101. For many countries, this is a real wonder;

- The most problematic elements of the unit (nozzles) are non-separable, which is why you need to buy expensive parts if you cannot clean them;

- You need to replace the air filter more often than usual.

Despite decent flaws, these engines give encouraging predictions that manufacturers will be able to create a unit in which the maximum of shortcomings will be eliminated.

Preventing malfunctions of GDI motors

If a motorist has decided to buy a car with a gdi system under the hood, then a simple prevention of malfunctions will help to extend the working life of the "heart muscle" of the car.

Since the efficiency of the gasoline supply system directly depends on the cleanliness of the nozzles, the first thing you need to pay attention to is periodic cleaning of the nozzles. Some manufacturers recommend using a special gasoline additive for this.

One option is Liqui Moly LIR. The substance improves the lubricity of the fuel by preventing clogging of the nozzles. The manufacturer of the product indicates that the additive works at high temperatures, removes carbon deposits and the formation of tar deposits.

Should you buy cars with GDI engines?

Naturally, the newest development, the more difficult it will be to maintain and capricious. As for the GDI engines, they demonstrate excellent gasoline economy (this cannot but please the ordinary motorist), but they do not lose power.

Despite these obvious advantages, power units have low reliability due to the very delicate operation of the fuel rail. They are picky about the cleanliness of the fuel. Even if a gas station has established itself as a quality service, its supplier may change, which is why no car owner is protected from counterfeiting.

Before deciding to buy such a vehicle, you need to decide for yourself whether you are ready to compromise in order to save fuel or not. But if there is a material base, then the advantage of such cars is clear.

In conclusion, a short video review of one instance of a direct injection internal combustion engine:

Watch this video on YouTube

History of GDI and PFI

Gasoline internal combustion engines have come a long way since Luigi de Cristoforis first invented the carburetor in 1876. However, mixing fuel with air in a carburetor before it enters the combustion chamber was still the main technology used in gasoline cars well into the 1980s.

It was only in this decade that original equipment manufacturers (OEMs) began moving away from carbureted engines to single point fuel injection to address some of the driveability issues and growing concerns about exhaust emissions. Although technology has evolved rapidly.

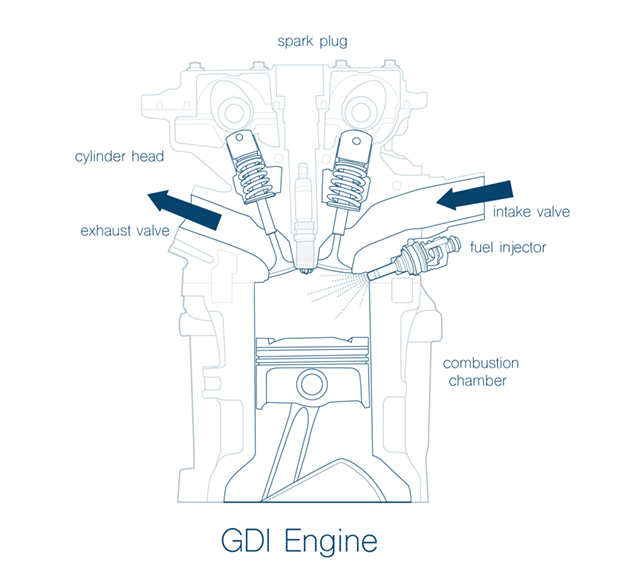

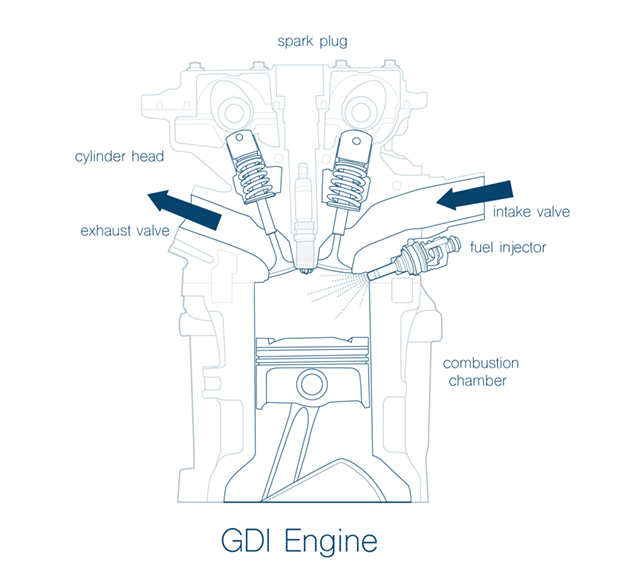

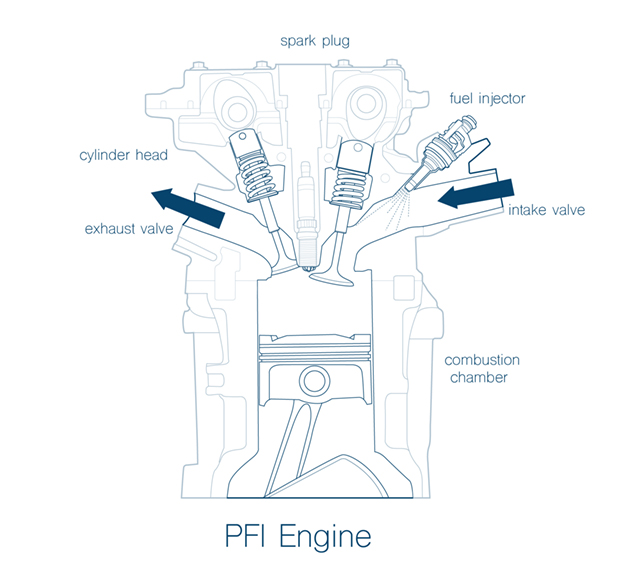

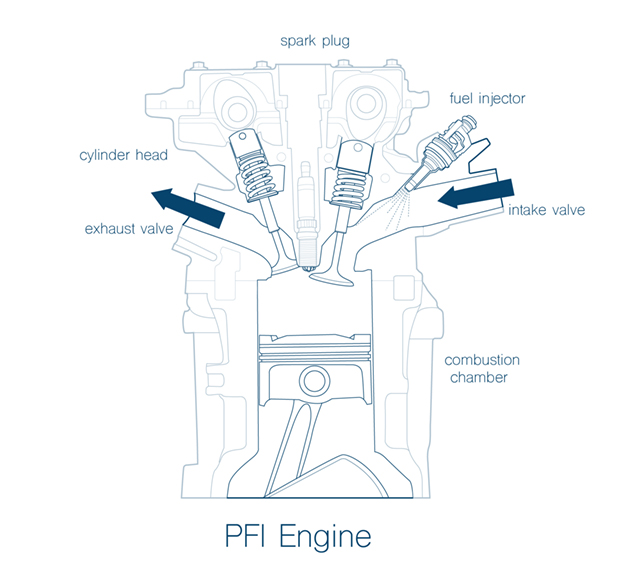

When PFI was introduced in the late 1980s, it was a big step forward in fuel injection design. It overcame many of the performance issues associated with single point injection and earlier carbureted engines. In port fuel injection (PFI) or multipoint fuel injection (MPFI), fuel is injected into the inlet of each combustion chamber through a special injector.

PFI engines use a three-way catalytic converter, exhaust sensors, and a computer-controlled engine management system to constantly adjust the ratio of fuel to air injected into each cylinder. However, technology is advancing and compared to today's direct injection (GDi) gasoline engine technology, PFI is not as fuel efficient and unable to meet today's increasingly stringent emission standards.

Differences between GDI and PFI engines

In a GDi engine, fuel is injected directly into the combustion chamber rather than into the intake port. The advantage of this system is that the fuel is used more efficiently. Without the need to pump fuel into the intake port, mechanical and pumping losses are significantly reduced.

In the GDi engine, the fuel is also injected at a higher pressure, so the fuel droplet size is smaller. The injection pressure exceeds 100 bar compared to the PFI injection pressure of 3 to 5 bar. The GDi fuel droplet size is <20 µm compared to the PFI droplet size of 120 to 200 µm.

As a result, GDi engines deliver higher power output with the same amount of fuel. On-board control systems balance the entire process and precisely control regulated emissions. The engine management system fires the injectors at the optimal moment for a specific time, depending on the need and driving conditions at that moment. At the same time, the on-board computer calculates whether the engine is running too rich (too much fuel) or too lean (too little fuel) and immediately adjusts the injector pulse width (IPW) accordingly.

The latest generation of GDi engines are complex machines operating to very tight tolerances. To improve fuel efficiency and reduce emissions, GDi technology uses precision components under high pressure conditions. Keeping the injector system clean is critical to engine performance.

The chemistry of fuel additives is based on understanding how these different engines work. Over the years, Innospec has adapted and refined its fuel additive packages to meet the latest engine technology requirements. The key to this process is understanding the engineering behind the various engine designs.

Frequently Asked Questions about GDI Engines

Here is a list of the most frequently asked questions about GDI engines:

Is the Gdi engine good?

Compared to non-GDI motors, the latter generally has a longer life and provides better performance than the former. must be done. As for servicing your GDI engine, you should do it on a regular basis.

How long will a Gdi engine last?

What makes a direct injection engine more durable? Direct injection gasoline engines have proven to be more durable than non-GDI engines. Generally, maintenance on a GDI engine starts when it is between 25 and 000 km and continues for several thousand miles after that. significant, however.

What is the problem with Gdi engines?

The most significant negative aspect (GDI) is the accumulation of carbon that occurs at the bottom of the intake valves. Carbon buildup occurs on the back of the intake valve. The result may be a computer code indicating engine misfiring. or inability to start.

Do Gdi engines need cleaning?

This is one of the best direct injection engines, but it requires regular maintenance. Those who drive these vehicles need to make sure they are up and running. The CRC GDI IVD intake valve cleaner can only be used every 10 miles due to their design.

Do Gdi engines burn oil?

PDI engines rage, engines burn oil? “When they are clean, GDI engines only burn a small percentage of oil, according to engine specifications. Starting with the accumulation of soot in the intake valves, these valves can fail.

How long do Gdi engines last?

However, in general, GDi cars need service every 25-45 km. Here's how to make it easier: Make sure the oil is changed according to the instructions, and use the oil if it's best needed.

Are Gdi engines noisy?

The increase in the use of gasoline direct injection (GDI) has dramatically increased fuel pressure in a vehicle, increasing the risk that the fuel system may produce more noise due to increased load.

What is better Mpi or Gdi?

Compared to conventional MPIs of comparable size, the GDI-designed motor delivers approximately 10% more performance at all speeds and torque at all output speeds. With an engine like GDI, the high performance version of the computer delivers outstanding performance.

Is the Gdi engine reliable?

Are Gdi engines reliable? ?Valve contaminants can be deposited on the intake valves of some GDI engines resulting in reduced engine performance, performance and reliability. Affected owners may have to pay extra. Sometimes cars with long life GDI engines do not accumulate dirt.

Do all Gdi engines need cleaning?

There is no time delay between the accumulation of soot in GDI engines. To avoid any potential engine problems caused by these deposits, the engine should be cleaned every 30 miles as part of a scheduled maintenance.

Why do Gdi engines burn oil?

Oil Evaporation: The increased pressure and temperature in GDi engines can cause oil to evaporate more quickly. These oil droplets tend to build up or form oil droplets due to oil vapor in the colder parts of the engine such as intake valves, pistons, rings and catalytic valves.

Is the Gdi engine good?

Compared to other engines on the market, Kia's Gasoline Direct Injection (GDI) engine is more efficient and powerful. A highly efficient and economical engine like the one used in Kia vehicles is not possible without it. Because it is economical yet very fast, GDI engine technologies provide a high level of speed and power.

What are the disadvantages of Gdi?

An increase in deposits on the piston surface leads to a sharp decrease in efficiency. Intake ports and valves continue to receive deposits. Low mileage misfire codes.

How often should a Gdi engine be cleaned?

It is important to remember that gasoline additives do not get on the intake valves of GDI engines. To prevent deposits from forming during a 10 mile trip or at every oil change, you should clean your vehicle every 000 miles.

How to keep a Gdi engine clean?

Improve fuel efficiency by replacing spark plugs after they have been driven for at least 10 miles. Adding detergent to premium fuel will prevent deposits from damaging engine parts. If the GDi system is out of order, replace the catalytic converter.

How often do you need to change the oil in a Gdi engine?

Gasoline direct injection, also known as GDI, is what it stands for. We also offer an engine cleaner and oil additive that removes carbon deposits, as well as an engine cleaner and oil additive that cleans the vehicle's fuel system. If your direct injection gasoline engine is between 5000 and 5000 miles, I recommend using Mobil 1 direct injection gasoline oil for maintenance.

What oil is recommended for a Gdi engine?

The most common oils I use when revising GDI and T/GDI fuel systems are Castrol Edge Titanium and Pennzoil Ultra Platinum, as well as Mobil 1, Total Quartz INEO and Valvoline Modern Oil. good at all of them.

Questions and answers:

How do GDI engines work? Outwardly, this is a classic gasoline or diesel unit. In such an engine, a fuel injector and a spark plug are installed in the cylinders, and gasoline is supplied under high pressure using a high-pressure fuel pump.

What gasoline for a GDI engine? For such an engine, gasoline with an octane rating of at least 95 is relied on. Although some motorists ride on the 92nd, detonation is inevitable in this case.

What are Mitsubishi GDI engines? To determine which Mitsubishi model uses a gasoline engine with direct fuel injection into the cylinders, you need to look for the GDI mark.