5.7 hemi engine - the most important news about the unit

Content

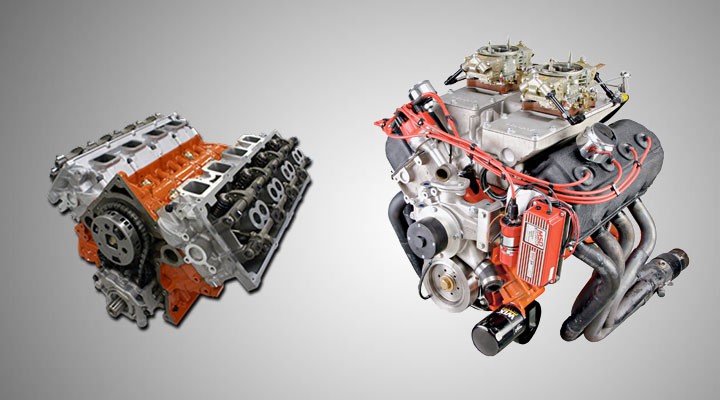

The 5.7 Hemi engine belongs to the group of units manufactured by Chrysler. A characteristic feature of the engine is that it is equipped with a semicircular combustion chamber. The product of the American concern was first introduced in 2003 on the occasion of the premiere of the Dodge Ram car - it was supplemented with a Magnum 5,9 engine. We present the most important information about him.

5.7 Hemi engine - basic information

2003 is associated not only with the premiere of the Dodge Rama, but also with the entire family of third-generation engines. The first was a 8cc V5 petrol engine. cm / 654 l codenamed Eagle. It replaced the Magnum V3 block mentioned in the introduction. The 5,7 Hemi engine was used in the Chrysler Dodge Durango, Charger, 8C, Magnum R/T, Jeep Grand Cherokee and Commander models.

Chrysler unit technical data

The four-stroke naturally aspirated engine has eight V-cylinders and two valves per cylinder. The valve train system is based on OHV valve timing. Bore 99,49 mm, stroke 90,88 mm, displacement 5 cc.

In the first models - until 2009, the compression ratio was 9,6: 1. Later it was 10,5:1. The 5.7 Hemi engine produced between 340 and 396 hp. (254-295 kW) and torque 08-556 Nm / 3,950-4,400 The engine oil volume was 6,7 l/l. In turn, the weight of the unit reached 254 kilograms.

Engine design 5.7 Hemi - what design solutions were used?

The 5.7 Hemi engine was completely redesigned from the ground up with a deep jacketed cast iron cylinder block and a 90° cylinder wall angle. Pre-2008 models had wider 1,50/1,50/3/0mm rings, while 2009 models featured the 1,20/1,50/3,0mm package.

The engineers also decided to install a cast ductile iron crankshaft, which was mounted with four bolts on each main bearing. The camshaft was also designed at a higher height to reduce the length of the pushrods. For this reason, the timing chain is longer and located between the cylinder banks.

The Hemi 5.7 is also equipped with crossflow aluminum cylinder heads, dual valves and spark plugs per cylinder. A flatter chamber was also made with shelves on both sides, which increased the efficiency of the drive unit.

Controls that contribute to good engine performance

The first control to look at is the camshaft. He is responsible for the operation of the intake and exhaust valves thanks to the pushers located in the valve levers. Important parts also include beehive valve springs and hydraulic roller tappets.

The designers also opted for the Multi-Displacement System cylinder deactivation system. This resulted in a significant reduction in fuel consumption as well as exhaust emissions. The technology works by shutting off fuel to four cylinders - two each - and leaving the intake and exhaust valves closed, controlling the flow of oil through individual valve lifters. The Hemi 5.7 is also equipped with a power operated electronic throttle.

Work engine 5.7 Hemi

In the case of this power unit, problems can arise with a run of 150-200 thousand km. This applies to malfunctions associated with broken valve springs or sticking and damage to the lever rollers. This is usually accompanied by ignition problems and a lit Check Engine light. Ignoring these symptoms may be due to severe camshaft failure or metal particles in the oil.

Should I choose a 5.7 hemi engine?

Despite these shortcomings, the 5.7 Hemi engine is a reasonably good, durable unit. One aspect that contributes to this is that it has a simple design - no turbocharging was used, which greatly increased its service life. The downside, however, is the rather high fuel consumption - up to 20 liters per 100 km.

With regular maintenance and oil changes every 9600 km, the engine will repay you with stable operation and a low failure rate. It should also be remembered that for proper operation of the power unit, it is necessary to use oil with a viscosity of SAE 5W20.

A photo. main: Kgbo via Wikipedia, CC BY-SA 4.0