Features of the device and advantages of the Common Rail fuel system

Content

In modern cars, fuel injection systems are used. If earlier such a modification was only in diesel power units, today many gasoline engines receive one of the types of injection. They are described in detail in another review.

Now we will focus on the development, which was named Common Rail. Let's see how it appeared, what is its peculiarity, as well as what are its advantages and disadvantages.

What is Common Rail Fuel System

The dictionary translates the concept of Common Rail as "accumulator fuel system". Its peculiarity is that a portion of diesel fuel is taken from a reservoir in which the fuel is under high pressure. The ramp is located between the injection pump and the injectors. The injection is carried out by the injector opening the valve and pressurized fuel is released into the cylinder.

This type of fuel system is the most recent step in the evolution of diesel powertrains. Compared to the gasoline counterpart, the diesel is more economical, since fuel is injected directly into the cylinder and not into the intake manifold. And with this modification, the efficiency of the power unit increases significantly.

Common rail fuel injection has improved the efficiency of the vehicle by 15%, depending on the settings of the internal combustion engine operating mode. In this case, usually a side effect of the economy of the motor is a decrease in its performance, but in this case, the power of the unit, on the contrary, increases.

The reason for this lies in the quality of the fuel distribution within the cylinder. Everyone knows that the efficiency of an engine directly depends not so much on the amount of incoming fuel as on the quality of its mixing with air. Since during the operation of the engine, the injection process occurs in a matter of fractions of a second, it is necessary that the fuel mixes with air as quickly as possible.

Fuel atomization is used to speed up this process. Since the line behind the fuel pump has a high pressure, diesel fuel is sprayed through the nozzles more efficiently. The combustion of the air-fuel mixture occurs with greater efficiency, from which the engine demonstrates an increase in efficiency several times.

History

The introduction of this development was the tightening of environmental standards for car manufacturers. However, the fundamental idea appeared in the late 60s of the last century. Its prototype was developed by the Swiss engineer Robert Huber.

A little later, this idea was finalized by an employee of the Swiss Federal Institute of Technology, Marco Ganser. This development was used by Denzo employees and created a fuel rail system. The novelty has received the uncomplicated name Common Rail. In the last years of the 1990s, the development appeared in commercial vehicles on EDC-U2 motors. Hino trucks (Rising Ranger model) received such a fuel system.

In the 95th year, this development also became available to other manufacturers. The engineers of each brand modified the system and adapted it to the characteristics of their own products. However, Denzo considers itself a pioneer in the use of this injection on cars.

This opinion is disputed by another brand, FIAT, which patented a prototype direct injection diesel engine (Chroma TDid model) in 1987. In the same year, the employees of the Italian concern began to work on the creation of electronic injection, which has a similar principle of work with a common rail. True, the system was named UNIJET 1900cc.

The modern injection variant functions on the same principle as the original design, regardless of who is considered to be its inventor.

Design

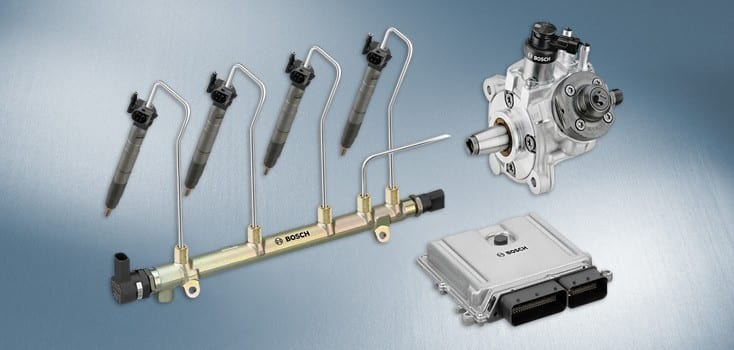

Consider the device of this modification of the fuel system. The high pressure circuit consists of the following elements:

- A line capable of withstanding high pressures, many times the compression ratio of the engine. It is made in the form of one-piece tubes to which all circuit elements are connected.

- Injection pump is a pump that creates the required pressure in the system (depending on the engine operating mode, this indicator can be more than 200 MPa). This mechanism has a complex structure. In its modern design, its work is based on a plunger pair. It is described in detail in another review... The device and principle of operation of the fuel pump is also described separately.

- A fuel rail (rail or battery) is a small thick-walled reservoir in which fuel accumulates. Injectors with atomizers and other equipment are connected to it using fuel lines. An additional function of the ramp is to damp the fluctuations of the fuel that occur during the operation of the pump.

- Fuel pressure sensor and regulator. These elements allow you to control and maintain the desired pressure in the system. Since the pump is constantly running while the engine is running, it constantly pumps diesel fuel into the line. To prevent it from bursting, the regulator discharges the excess working medium into the return line, which is connected to the tank. For details on how the pressure regulator works, see here.

- The injectors supply the required portion of fuel to the unit cylinders. Diesel engine developers decided to place these elements directly in the cylinder head. This constructive approach allowed several complex issues to be addressed simultaneously. Firstly, it minimizes fuel losses: in the intake manifold of the multipoint injection system, a small part of the fuel remains on the manifold walls. Secondly, a diesel engine ignites not from a glow plug and not from a spark, as in a gasoline engine - its octane number does not allow the use of such ignition (what is the octane number, read here). The piston compresses the air strongly when the compression stroke is performed (both valves are closed), causing the temperature of the medium to rise to several hundred degrees. As soon as the nozzle atomizes the fuel, it ignites spontaneously from the high temperature. Since this process requires perfect precision, the devices are equipped with solenoid valves. They are triggered by a signal from the ECU.

- Sensors monitor the operation of the system and send appropriate signals to the control unit.

- The central element in Common Rail is the ECU, which is synchronized with the brains of the entire onboard system. In some car models, it is integrated into the main control unit. Electronics can record not only the performance of the engine, but also other components of the car, due to which the amount of air and fuel, as well as the moment of spraying, is more accurately calculated. The electronics are factory programmed. As soon as the ECU receives the necessary information from the sensors, the specified algorithm is activated, and all the actuators receive the appropriate command.

- Any fuel system has a filter in its line. It is installed in front of the fuel pump.

A diesel engine equipped with this type of fuel system operates according to a special principle. In the classic version, the entire fuel portion is injected. The presence of a fuel accumulator makes it possible to distribute one portion into several parts while the motor is performing one cycle. This technique is called multiple injection.

Its essence boils down to the fact that before the main amount of diesel fuel is supplied, a preliminary injection is made, which heats up the working chamber even more, and also increases the pressure in it. When the rest of the fuel is sprayed, it ignites more efficiently, giving the common rail ICE high torque even when the engine speed is low.

Depending on the operating mode, part of the fuel will be supplied once or twice. When the engine is idling, the cylinder is warmed up by a dual pre-injection. When the load increases, one pre-injection is performed, which leaves more fuel for the main cycle. When the engine is running at maximum load, no pre-injection is performed, but the entire fuel load is used.

Development prospects

It is worth noting that this fuel system has improved as the compression of the power units increases. Today, car owners are offered the 4th generation of Common Rail. In it, the fuel is under a pressure of 220 MPa. This modification has been installed on cars since 2009.

The previous three generations had the following pressure parameters:

- Since 1999, the rail pressure has been 140MPa;

- In 2001, this figure increased by 20MPa;

- 4 years later (2005) cars began to be equipped with the third generation of fuel systems, which were capable of creating a pressure of 180 MPa.

Increasing the pressure in the line allows for the injection of a larger volume of diesel fuel in the same period of time as in previous developments. Accordingly, this increases the gluttony of the car, but the increase in power is noticeably increased. For this reason, some restyled models receive a motor identical to the previous one, but with increased parameters (how the restyling differs from the next generation model is described separately).

Improving the efficiency of this modification is carried out due to more accurate electronics. This state of affairs allows us to conclude that the fourth generation is not yet the pinnacle of perfection. However, the increase in the efficiency of fuel systems is provoked not only by the desire of automakers to satisfy the needs of economical motorists, but primarily by raising environmental standards. This modification provides a better combustion of the diesel engine, so that the car is able to pass quality control before leaving the assembly line.

Common rail advantages and disadvantages

The modern modification of this system has made it possible to increase the power of the unit by spraying more fuel. Since in modern auto manufacturers install a large number of all kinds of sensors, electronics began to more accurately determine the amount of diesel fuel required to operate the internal combustion engine in a specific mode.

This is the main advantage of the common rail over the classic vehicle modifications with unit injectors. Another plus in favor of an innovative solution is that it is easier to repair, since it has a simpler device.

The disadvantages include the high cost of the installation. It also requires higher quality fuel. Another disadvantage is that the injectors have a more complex design, therefore they have a shorter working life. If any of them fails, the valve in it will be constantly open, which will break the tightness of the circuit and the system will shut down.

More details about the device and different versions of the high pressure fuel circuit are discussed in the following video:

Questions and answers:

What is the pressure on the Common Rail? In the fuel rail (accumulator tube), fuel is supplied under low pressure (from vacuum to 6 atm.) And in the second circuit under high pressure (1350-2500 bar.)

What is the difference between Common Rail and fuel pump? In fuel systems with a high-pressure pump, the pump immediately distributes the fuel to the injectors. In the Common Rail system, fuel is pumped into an accumulator (tube) and from there it is distributed to the injectors.

Who invented the Common Rail? A prototype common rail fuel system appeared in the late 1960s. It was developed by the Swiss Robert Huber. Subsequently, the technology was developed by Marco Ganser.

One comment

Stephen

How does high blood pressure occur?