What is a particulate filter, its structure and principle of operation

Content

- What is a particulate filter and how does it work?

- Where is a particulate filter located and what is it for?

- Filter device

- Features of the operation and operation of the particulate filter

- DPF closed-type particulate filters

- FAP closed-type particulate filters with regeneration function

- Particulate filter regeneration

- How to care for a particulate filter

- Can the particulate filter be removed?

- Instead of a conclusion

- Questions and answers:

With the introduction of environmental standards, starting in 2009, all cars with self-igniting internal combustion engines must be equipped with particulate filters. Consider why they are needed, how they work and how to care for them.

What is a particulate filter and how does it work?

The very concept of a filter indicates that the part is involved in the cleaning process. Unlike the air filter, the particulate filter is installed in the exhaust system. The part is designed to minimize the emission of harmful substances into the atmosphere.

Depending on the quality of the product and filter elements, this part is capable of removing up to 90 percent of soot from the exhaust after diesel fuel combustion. The work of the Federation Council takes place in two stages:

- Removal of soot. Smoke-permeable filter elements trap particulate matter. They settle in the cells of the material. This is the main task of the filter.

- Regeneration. This is a procedure for cleaning the cells from accumulated soot. It is produced when, with serviceable associated systems, the motor begins to lose power. In other words, regeneration is the restoration of the cleanliness of the cell surface. Different modifications use their own technology for cleaning soot.

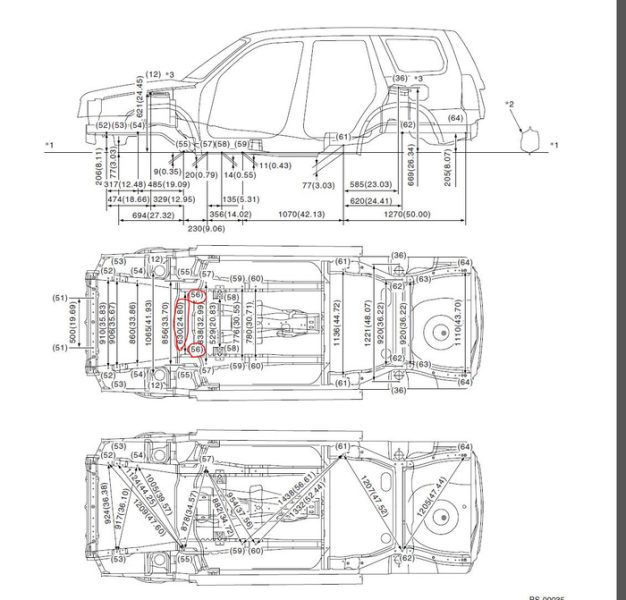

Where is a particulate filter located and what is it for?

Since SF is involved in exhaust cleaning, it is installed in the exhaust system of a car powered by a diesel engine. Each manufacturer equips its cars with a system that may differ from analogues of other brands. For this reason, there is no hard and fast rule about where the filter should be.

In some cars, the carbon black is used in conjunction with a catalyst, which is installed in all modern cars equipped with a gasoline engine. In this case, the filter can either be in front of the catalytic converter or after it.

Some manufacturers (for example Volkswagen) have created combination filters that combine the functions of both a filter and a catalyst. Thanks to this, the cleanliness of the exhaust from a diesel engine does not differ from a gasoline analogue. Often, such parts are installed immediately after the exhaust manifold so that the temperature of the exhaust gases ensures the proper chemical reaction to neutralize harmful substances.

Filter device

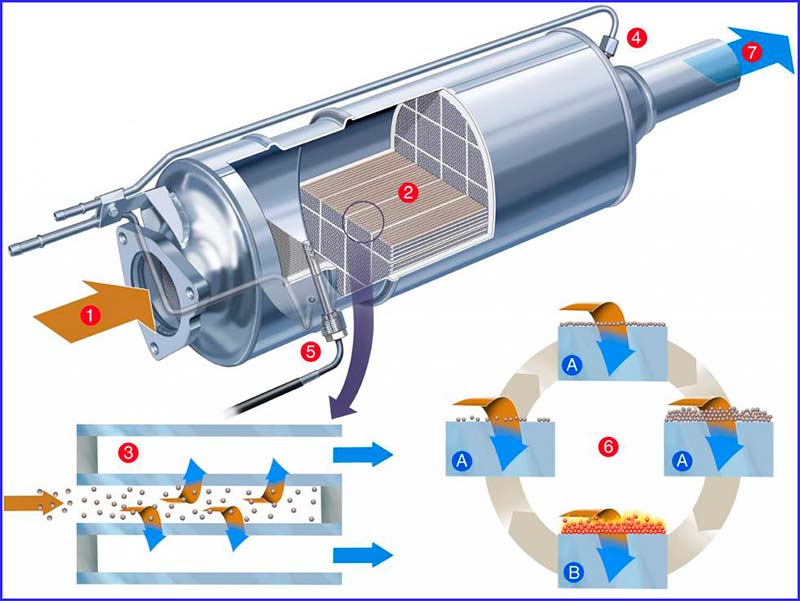

In the classic version, the DPF device is very similar to the catalytic converter. It has the shape of a metal flask, only inside it there is a durable filtering element with a cell structure. This element is often made from ceramic. The filter body has a lot of 1mm mesh.

In combined versions, the catalyst elements and the filter element are placed in one module. In addition, a lambda probe, pressure and exhaust gas temperature sensors are installed in such parts. All these parts ensure the most efficient removal of harmful particles from the exhaust.

Features of the operation and operation of the particulate filter

The service life of particulate filters directly depends on the operating conditions of the vehicle. Depending on this, the car owner needs to check the condition of the filter every 50-200 thousand kilometers. If the car is operated in urban conditions and often finds itself in traffic jams, then the filter life will be less compared to the analogue installed in a car that is operated in lighter conditions (long-distance trips along the highway). For this reason, the indicator of engine hours of the power unit plays a significant role.

Since a clogged particulate filter reduces engine performance, every motorist needs to periodically regenerate the exhaust system. Also of great importance is compliance with the regulations for replacing engine oil. Therefore, the car owner must closely adhere to the recommendations of the car manufacturer.

Diesel oil selection

Just like the catalytic converter found in modern gasoline vehicles, the particulate filter can be seriously damaged if the owner of the car uses the wrong engine oil. In this case, the lubricant can enter the cylinders and burn out on the stroke of the stroke.

In this case, a large amount of soot will be released (this depends on the volume of incoming oil), which should not be present in the exhaust system of the car. This soot enters the filter cells and forms deposits on them. For diesel engines, the Association of European Automobile Manufacturers has established an engine oil standard that meets the requirements of an environmental standard of at least Euro4.

The package with such oil will be labeled C (with indices from 1 to 4). Such oils are designed specifically for vehicles equipped with an exhaust gas aftertreatment or purification system. Due to this, the service life of the particulate filter is increased.

Auto cleaning

During operation of the power unit, physical processes can be started that automatically clean the particulate filter from carbon deposits. This happens when the exhaust gases entering the filter tank are heated to +500 degrees and above. During the so-called passive auto-cleaning, the soot is oxidized by the incandescent medium and breaks off from the surface of the cells.

But for this process to start, the motor must run at a certain speed for a long time. When the car is in a traffic jam and often travels short distances, the exhaust gases do not have time to warm up to such an extent. As a result, soot accumulates in the filter.

To help drivers who operate their cars in this mode, manufacturers of various auto chemicals have developed special anti-soot additives. Their use allows you to start auto-cleaning of the filter at an exhaust gas temperature within +300 degrees.

Some modern cars are equipped with a forced regeneration system. It injects some fuel which ignites in the catalytic converter. Due to this, the particulate filter heats up and plaque is removed. This system works on the basis of pressure sensors installed before and after the particulate filter. When there is a large difference between the readings of these sensors, the regeneration system is activated.

Some manufacturers, for example, Peugeot, Citroen, Ford, Toyota, instead of an additional portion of fuel to warm up the filter, use a special additive, which is located in a separate tank. This additive contains cerium. The regeneration system periodically adds this substance to the cylinders. The additive forcibly heats the exhaust gases to a temperature of about 700-900 degrees. If the car is equipped with a variation of such a system, he does not need to do anything to clean the particulate filter.

DPF closed-type particulate filters

Diesel particulate filters in modern design are divided into two types:

- dpf closed-type filters;

- fap filters with filter element regeneration function.

The first category includes elements with ceramic honeycomb inside, as in a catalytic converter. A thin titanium layer is applied to their walls. The effectiveness of such a part depends on the exhaust temperature - only in this case a chemical reaction will occur to neutralize carbon monoxide. For this reason, these models are installed as close to the exhaust manifold as possible.

When deposited on a ceramic honeycomb with a titanium coating, soot and carbon monoxide are oxidized (the temperature at which the reaction occurs must be several hundred degrees). The presence of sensors allows you to diagnose a filter malfunction in time, about which the driver will receive a notification from the ECU on the car's tidy.

FAP closed-type particulate filters with regeneration function

FAP filters are also of closed type. Only they differ from the previous ones by the self-cleaning function. Soot does not accumulate in such flasks. The cells of these elements are covered with a special reagent that reacts with hot smoke and completely removes particles from the exhaust tract at high temperatures.

Some modern cars are equipped with a special flushing system that injects a reagent at the right time when the car is moving, due to which soot is removed already in the early stages of formation.

Sometimes, instead of an additive, an additional portion of fuel is used, which burns out in the filter itself, increasing the temperature inside the flask. As a result of burning, all particles are completely removed from the filter.

Particulate filter regeneration

When diesel fuel burns, a large amount of particulate matter is released. Over time, these substances settle on the inside of the channels of the soot, from which it becomes clogged.

If you fill up with bad fuel, there is a high probability that a large amount of sulfur will accumulate in the filter element. It prevents the high-quality combustion of diesel fuel, promotes an oxidative reaction in the exhaust system, due to which its parts will fail faster.

However, a rapid contamination of the particulate filter can also occur due to improper tuning of the diesel engine. Another reason is incomplete combustion of the air-fuel mixture, for example, due to a failed nozzle.

What is regeneration?

Filter regeneration means cleaning or restoring clogged filter cells. The procedure itself depends on the filter model. And also on how the car manufacturer set up this process.

In theory, the soot cannot completely clog, since chemical reactions must take place in it. But in practice, this often happens (the reasons are indicated a little above). For this reason, manufacturers have developed a self-cleaning function.

There are two algorithms for performing regeneration:

- Active;

- Passive.

If the vehicle is unable to clean the catalyst and filter on its own, you can do this procedure yourself. It will be required in the following cases:

- The car rarely travels long distances (the exhaust does not have time to warm up to the desired temperature);

- The internal combustion engine was muffled during the regeneration process;

- Defective sensors - the ECU does not receive the required pulses, which is why the cleaning procedure does not turn on;

- At a low fuel level, regeneration does not take place, since it requires an additional amount of diesel;

- EGR valve malfunction (located in the exhaust gas recirculation system).

A sign of a clogged filter is a sharp decrease in the power of the power unit. In this case, washing the filter element with the help of special chemicals will help to solve the problem.

The particulate filter does not require mechanical cleaning. It is enough to remove the part from the exhaust system and close one of the holes. Further, a universal emulator is poured into the container. It helps remove plaque without having to buy a new part. The liquid must completely cover the contaminated surface. For 12 hours, the part must be shaken periodically so that the soot lags behind better.

After using the cleaner, the part is washed under running water.

Passive regeneration

This process is performed while the motor is running under load. When the car is driving on the road, the exhaust temperature in the filter rises to about 400 degrees. These conditions provoke a chemical reaction to oxidize the soot.

During the regeneration process, nitrogen dioxide is generated in such filters. This substance acts on the carbon compounds that make up soot. This process forms nitric oxide together with carbon monoxide. Further, due to the presence of oxygen in the cavity, these two substances enter into a reaction with it, as a result of which two other compounds are formed: CO2 and nitrogen dioxide.

It should be borne in mind that such a process is not always equally effective, therefore, periodically it is necessary to carry out forced cleaning of the soot dpf.

Active regeneration

To prevent the particulate filter from failing and not having to change it to a new one, it is necessary to periodically clean the active surface of the catalyst. In city traffic or short-distance travel, it is impossible to provide passive cleaning of the catalyst.

In this case, it is necessary to start an active or forced procedure. Its essence boils down to the following. The Ugr valve closes (if necessary, adjustments are made to the operation of the turbine). In addition to the main portion of fuel, a certain amount of air-fuel mixture is formed.

It is fed into the cylinder, in which it partially burns out. The remainder of the mixture enters the exhaust manifold and enters the catalyst. There it burns out and the exhaust temperature rises - the effect of a blast furnace with the blower turned on is formed. Thanks to this effect, the particles accumulated in the catalyst cells are burned out.

Such a procedure is necessary for the chemical reaction to continue in the catalytic converter. This will allow less soot to enter the filter, which in turn will increase the life of the particle filter.

In addition to cleaning the catalyst, the combustion of an additional portion of VTS outside the engine increases the temperature in the filter circuit itself, which also partially contributes to its cleaning.

The driver learns that the electronics are performing this procedure to briefly increase the idle speed during a long trip. As a result of this self-cleaning, darker smoke will come out of the exhaust pipe (this is the norm, since soot is removed from the system).

Why regeneration can fail and how to do a manual cleanup

There are several reasons why the particulate filter does not regenerate. For instance:

- Short trips, due to which the process does not have time to start;

- Regeneration is interrupted due to motor stop;

- One of the sensors does not transmit readings or there is no signal from it at all;

- Low level of fuel or additives in the tank. The system determines how much fuel or anti-particulate additive is needed for a complete regeneration. If the level is low, then the process will not start;

- EGR valve malfunction.

If the machine is operated in such conditions that self-cleaning will not start, the particulate filter can be cleaned manually. In this case, it must be removed from the vehicle. Next, one outlet must be plugged with a stopper, and flushing liquid is poured into the other. Periodically, the filter must be shaken to break off the soot.

It is necessary to allocate about 12 hours for washing the filter. After this time, the washing is drained, and the filter itself is washed with clean running water. Although this procedure can be performed independently, it is better to take the car to a service station for this to combine with the diagnosis of the entire exhaust system. In this case, it is not necessary to spend so much time. For example, some service stations have special equipment that simulates the process of filter regeneration by forced soot burning. A special heater and fuel injection can be used, which simulates the operation of a regeneration system.

Causes of increased soot formation

The key parameter affecting the cleanliness of the particulate filter is the poor quality of the fuel. Diesel fuel of this quality can have a large amount of sulfur in the stave, which not only prevents the fuel from completely burning out, but also provokes an oxidative reaction of the metal. If it was noticed that after a recent refueling, the system starts regeneration more often, then it is better to look for another refueling.

Also, the amount of soot in the filter depends on the settings of the power unit itself. For example, when the injection occurs incorrectly (it does not spray, but squirts, due to which an inhomogeneous air-fuel mixture is formed in one part of the chamber - enriched).

How to care for a particulate filter

Just like other parts that are subject to stress, the particulate filter also needs periodic maintenance. Of course, if the engine, fuel system and all sensors are properly configured in the car, then less soot will form in the soot, and regeneration will occur as efficiently as possible.

However, there is no need to wait for the engine error light on the dashboard to illuminate to check the condition of the particulate cell. Diagnostics of the car will help in the early stages to determine the clogging of the SF.

Its service life can be extended by using a special flush or cleaner, which allows you to quickly and safely remove soot deposits from the filter.

Service life and replacement of the particulate filter

Despite the start of automatic cleaning, the particulate filter still becomes unusable. The reason for this is the constant work in the high temperature zone, and during regeneration this figure rises significantly.

Usually, with proper engine operation and using high-quality fuel, the filter is able to move about 200 thousand kilometers. But in some regions, high-quality fuel is not always available, which is why it is necessary to pay attention to the condition of the particulate filter earlier, for example, every 100 km.

There are times when the filter remains intact even with a run of 500 thousand. One way or another, each motorist must independently pay attention to the behavior of the vehicle. A key factor indicative of problems with a particulate filter is a significant decrease in engine power. Also, the engine will start to take a lot of oil, and blue smoke may appear from the exhaust system and an uncharacteristic sound in the operation of the internal combustion engine.

Can the particulate filter be removed?

If you just say, then it's real to do it. Only the second question - what's the point if the car in this case will not meet environmental standards. In addition, the electronic control unit is configured to control the operation of this element. If you remove it from the system, then a permanent software failure will occur in the electronics.

Some take this step and put a snag for the following reasons:

- There will be no need to service an additional part of the machine;

- A new particulate filter is quite expensive;

- The fuel consumption is slightly reduced, since the regeneration process will not be carried out;

- Slightly, but still the motor power will increase.

However, this solution has many more disadvantages:

- The very first is non-compliance with any environmental standards;

- The color of the exhaust will change noticeably, which will create a problem in a big city, especially in summer and in traffic jams (there is not enough air anyway, and then a puffing car nearby forces you to turn on the air circulation inside the car);

- You can forget about trips to the EU countries, because the car will not be allowed across the border;

- Disabling some sensors will cause the control unit software to malfunction. To solve the problem, you will need to flash the ECU. The cost of firmware is high and the consequences can be unpredictable. Resetting the data in the control unit will raise a lot of questions that will not make it possible to sell the car at an acceptable price.

These are just some of the negative aspects of the DPF notch. But they should be enough to drop the idea and start restoring, cleaning or buying a new particulate filter.

Instead of a conclusion

Deciding whether to remove the particulate filter from a vehicle's exhaust system is a personal decision of every motorist. If in the case of old cars this problem is solved at the factory level (SFs are rarely found), then some new generation cars will not work at all without it. And the number of such cars is not decreasing, because a worthy replacement for the diesel engine has not yet been released.

It is better not to experiment with cars equipped with complex electronic systems, since if there is a constant error, the ECU can go into emergency mode.

For more information on the particulate filter, see the video:

Related videos

In addition, we offer a detailed video on how the particulate filter is regenerated:

Watch this video on YouTube

Questions and answers:

Can the particulate filter be cleaned? To do this, you need to remove it, fill it with a special cleaning liquid and after about 8 hours rinse and put in place. Flushing can also be performed without removing the part from the car.

How often do you need to change the particulate filter? Any particulate filter is clogged. Usually, its replacement is required on average after 200 thousand kilometers, but this is influenced by the quality of the fuel, the composition of the military-technical cooperation and the number of operating hours.

Can I drive without a particulate filter? In technical terms, this will not negatively affect the car. But the electronics will constantly fix the error, and the exhaust will not meet eco-standards.