The device and principle of operation of the air suspension

Content

In the description of premium car models of the latest generations, the concept of adaptive suspension is often found. Depending on the modification, this system can adjust the shock absorber stiffness (a sports car has a hard look, an SUV is softer) or ground clearance. Another name for such a system is air suspension.

Those who drive on roads of different quality pay attention to the presence of this modification: from smooth motorways to off-road trips. Fans of car tuning specifically install such pneumatic elements that allow the car to even bounce. This direction in auto tuning is called low-ride. There is separate review.

Basically, the pneumatic type of suspension is installed on freight vehicles, but business or premium passenger vehicles often receive a similar system. Consider the device of this type of machine suspension, how it will work, how the pneumatic system is controlled, and also what are its advantages and disadvantages.

What is air suspension

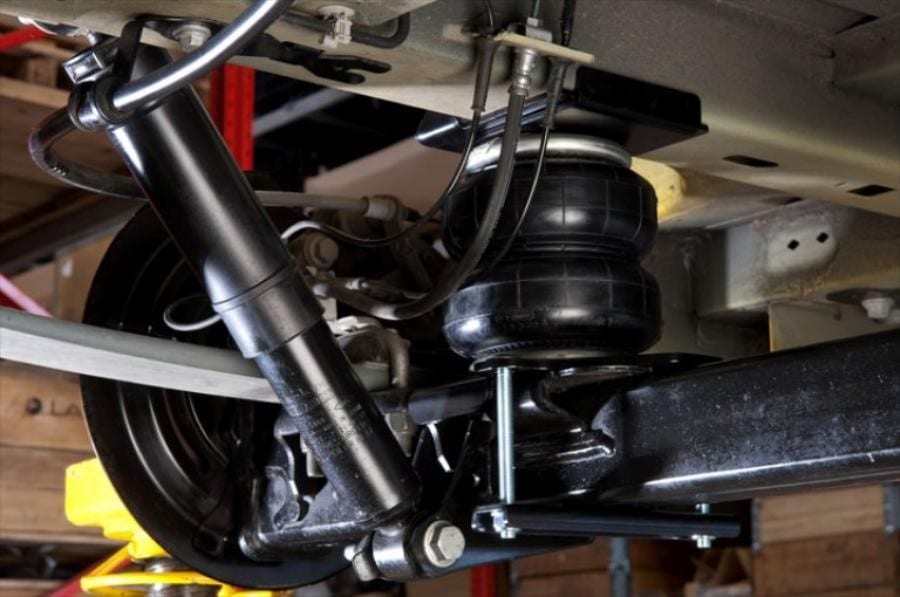

Air suspension is a system in which pneumatic elements are installed instead of standard shock absorbers. Any 18-wheeled truck or modern bus is equipped with similar mechanisms. With regard to redesigns of standard vehicles, the classic spring-type suspension is usually upgraded. The factory strut (MacPherson strut in front, and a spring or spring in the back) changes to air bellows, which are installed in the same way as the factory design, but for this special fasteners are used.

You can buy a similar part in large stores specializing in car tuning. For spring or torsion suspension modifications, there are also separate mounting kits.

If we talk about car suspension, then it is designed to absorb shocks and shocks coming from the wheels to the supporting body or frame of the car. Such a trolley not only provides maximum comfort while driving on uneven roads. First of all, this system is designed so that the car does not fall apart after a couple of years of operation.

In standard suspensions, vehicle clearance (the description of this term is here) remains unchanged. If the vehicle is operated in different conditions, then it would be practical to have a suspension that can change the ground clearance depending on the condition of the road.

For example, when driving at high speed on a motorway, it is important that the car is as close to the asphalt so that the aerodynamics work in favor of the car's downforce. This increases the stability of the car when cornering. Details about the aerodynamics of cars here... On the other hand, to overcome off-road conditions, it is important that the position of the body relative to the ground is as high as possible so that the underside of the car is not damaged during movement.

The first pneumatic suspension in production models was developed by Citroen (19 DC1955). General Motors is another manufacturer that has tried to introduce pneumatics into the automotive industry.

The production car of this brand, which was equipped with active air suspension, was a 1957 Cadillac Eldorado Brige. Due to the high cost of the mechanism itself and the complexity of repair, this development was frozen indefinitely. Thanks to modern technologies, this system has been refined and introduced into the automotive industry.

Features of car air suspension

By itself, air suspension, at least the technology, exists only in theory. In fact, air suspension means a whole system consisting of a large number of nodes and mechanisms. Pneumatics in such a suspension is used exclusively in one node - instead of standard springs, torsion bars or springs.

Despite this, the air suspension has a number of advantages over the classical design. Key among these is the ability to change the vehicle's ride height or suspension stiffness.

The air suspension cannot be used in its pure form (only air springs) without additional mechanisms or structures. For example, it is more effective when using the same elements that are used in the MacPherson strut, in the multi-link suspension, and so on.

Since the air suspension uses a large number of different additional elements, its cost is very high. For this reason, it is not installed by the manufacturer on budget cars.

Such a system has been widely used in freight transport. Due to the fact that trucks and buses carry heavy loads, air suspension in such vehicles uses a full range of properties. In passenger vehicles, fine-tuning of the suspension is impossible solely by mechanics, so the system is often controlled electronically in conjunction with adjustable shock absorbers. Such a system is known to many motorists under the name "adaptive suspension".

Patrimony

The air bag was patented by William Humphries in 1901. Although this device had a number of advantages, it was not immediately noticed, and then only by the military. The reason is that installing an air spring on a truck gave him more advantages, for example, such a car could be loaded more, and the increased ground clearance increased the off-road transport ability.

In civilian vehicles, air suspension was introduced only in the 30s of the last century. This system was installed in the Stout Scarab model. The vehicle was equipped with four Fairstone air bellows. In that system, the compressor was driven by a belt drive connected to the power unit. The machine used a four-circuit system, which is still considered the most successful solution.

Some companies have tried to improve the air suspension system. A lot has been done by Air Lift. It is associated with the introduction of air suspension in the world of motorsport. This system was used on the cars of American bootleggers (illegal carriers of moonshine during the Prohibition era). Initially, various modifications of their vehicles were used to elude the police. Over time, the drivers began to arrange races among themselves. This is how the race, which today is called NASCAR (competition on pumped stock cars), was born.

The peculiarity of this suspension was that the pillows were installed inside the springs. It was used until the 1960s. The first outrigger systems were poorly thought out, which made such a project a failure. Nevertheless, some cars were equipped with such a suspension already at the factory.

Since air suspension was very popular in sports cars, large automakers drew attention to this technology. So, in 1957, the Cadillac Eldorado B linkedin appeared. The car received a full-fledged four-circuit air suspension with the ability to adjust the pressure in each individual pillow. Around the same time, this system was introduced by Buick and Ambassador.

Among European automakers, Citroen has deservedly the first place in the use of air suspension. The reason is that the brand's engineers introduced innovative developments that made car models with this system popular (some of them are still appreciated by collectors).

In those years, it was accepted that a car could not be both comfortable and equipped with an advanced air suspension. Citroen shattered this stereotype with the release of the iconic DS 19.

The car used an innovative hydropneumatic suspension. Unprecedented comfort was ensured by lowering the pressure in the gas chambers of the cylinders. In order for the car to be as controllable as possible at high speed, it was enough to increase the pressure in the cylinders, making the suspension stiff. And although nitrogen was used in that system, and the level of comfort was assigned to the hydraulic part of the system, it is still considered a pneumatic system.

In addition to the French manufacturer, the German company Borgward was engaged in the development and implementation of air suspension. This example was followed by the Mercedes-Benz car brand. Today it is impossible to create a budget car with air suspension, because the system itself is very expensive to manufacture, repair and maintain. As at the dawn of this technology, today the air suspension is installed only on cars of the Premium segment.

How Air Suspension Works

The work of the air suspension boils down to achieving two goals:

- In a given mode, the car must maintain the position of the body relative to the road surface. If the sport setting is selected, then the clearance will be minimal, and for off-road performance, on the contrary, the highest.

- In addition to its position in relation to the road, the air suspension must be able to absorb any unevenness in the road surface. If the driver selects the sporty driving mode, then each shock absorber will be as hard as possible (it is important that the road is as flat as possible), and when the off-road mode is set, it will be as soft as possible. However, the pneuma itself does not change the stiffness of the shock absorbers. For this, there are special models of damping elements (in detail about the types of shock absorbers is described here). The pneumatic system only allows you to raise the car body to the maximum permissible height or lower it as much as possible.

Each manufacturer tries to outperform the competition by creating improved systems. They may call their designs differently, but the concept of how the devices work remains the same. Regardless of the modification of the actuators, each system will consist of the following elements:

- Electronic circuit. Electronics better provides fine tuning of the operation of the actuators. Some cars get an adaptive type of systems. In this modification, many different sensors are installed that record the operating mode of the motor, wheel rotation, the state of the road surface (for this, a sensor can be used night vision systems or front camera) and other vehicle systems.

- Executive mechanisms. They are different in size, design and principle of operation, but they always provide a mechanical drive, due to which the car is raised or lowered. Pneumatics can be air or hydraulic driven. In the air modification, a compressor is installed (or a hydrocompressor in a system filled with working fluid), a receiver (compressed air accumulates in it), a dryer (removes moisture from the air so that the inside of the mechanisms does not rust) and a pneumatic cylinder on each wheel. The hydraulic suspension has a similar design, except that stiffness and ground clearance are not controlled by air, but by a working fluid that is pumped into a closed circuit, such as in a braking system.

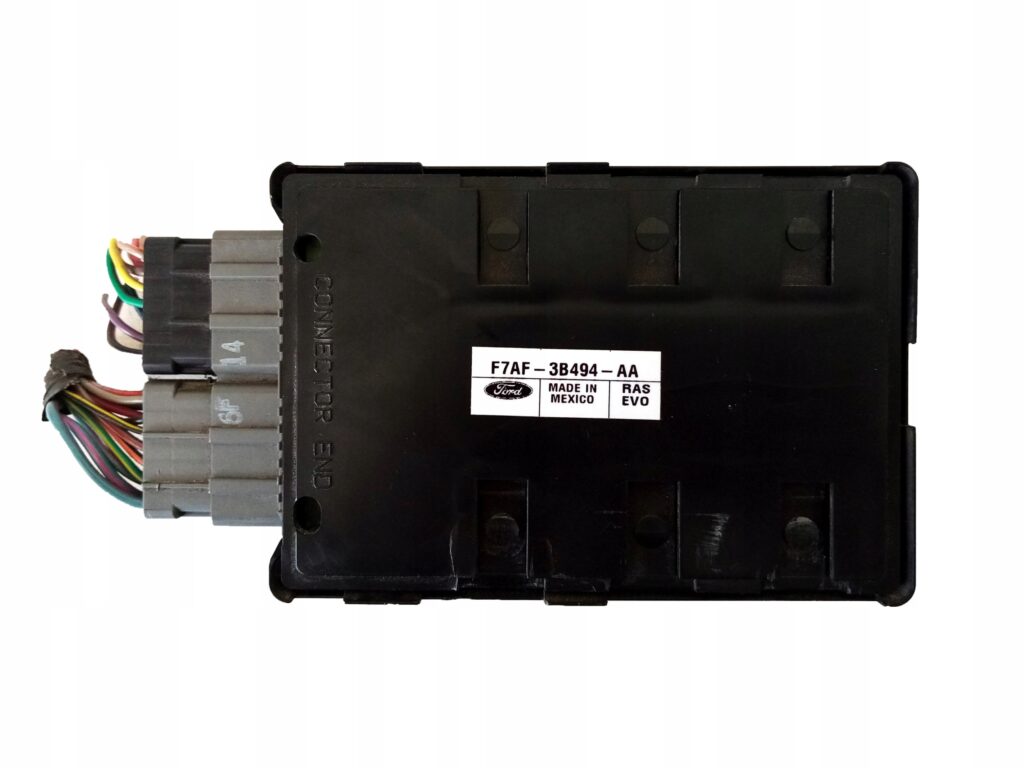

- Control system. In every car with such a suspension, a special regulator is installed on the control panel, which activates the corresponding electronics algorithm.

In addition to factory systems, there are simpler modifications for amateur tuning. This type is controlled by a remote control that is installed in the passenger compartment. With the help of the regulator, the driver changes the vehicle's ground clearance. When the device is activated by the compressor, air is pumped into the pneumatic accumulator, creating the required pressure.

This modification provides only a manual mode for adjusting the clearance. The driver can only activate a specific electric valve (or group of valves). In this case, the air suspension is raised or lowered to the desired height.

The factory version of pneumatic suspensions can have an automatic principle of operation. In such systems, an electronic control unit is necessarily present. Automation works using signals from sensors for wheels, motor, body position and other systems, and itself adjusts the height of the car.

Why Install Air Suspension

Typically, a simple air bag is installed on the vehicle's rear suspension assembly. This modification can be found on many crossovers и SUVs... The dependent type of suspension has little effect from such a modernization, since even with high ground clearance on irregularities, the cross member will still cling to irregularities or obstacles.

For this reason, the rear air springs are used in conjunction with an independent multi-link design, such as the new Land Rover Defender. A test drive of the second generation of this full-fledged SUV is here.

These are the reasons why some motorists are modernizing the suspension part of the car's undercarriage.

Adjustability

When the car is loaded (all seats are occupied in the cabin or the body is full), in a classic car the springs are compressed under the weight of the additional load. If the vehicle travels on uneven terrain, it may catch on the bottom of the protruding obstacles. It can be a stone, a bump, the edge of a pit, or a track (for example, on an unclean road in winter).

Adjustable ground clearance will allow the motorist to overcome obstacles on the road as if he were not loaded. Adjusting the height of the car takes place not in a few weeks of alteration of the chassis, but in a couple of minutes.

Automatic air suspension allows you to more accurately adjust the position of the car, depending on the preferences of the car owner. At the same time, there is no need to carry out complex adjustments to the vehicle structure.

Controllability

In addition to adjusting the clearance to the selected mode, the system compensates as much as possible even a small angle of inclination of the car at speed (in expensive models). To ensure that all wheels on bends have maximum grip on the road surface, based on the signals from the body position sensors, the control unit can give a command to the solenoid valves of each of the wheels.

When entering a turn in one circuit, the pressure increases, due to which the machine on the axis of the inner turning radius rises slightly. This makes it easier for the driver to drive the vehicle, which increases traffic safety. When the maneuver is completed, air is released from the loaded circuit, and the automation stabilizes the position of the car body.

In conventional vehicles, this function is performed by the lateral stabilizer. In budget models, this part is installed on the drive axle, but in the more expensive segment, two transverse and even longitudinal stabilizers are used.

The air spring has one useful property. Its recoil stiffness directly depends on the compression ratio. In expensive systems, it is possible to use air springs, which prevent the vehicle from swaying while driving over bumps. In this case, the mechanical element is controlled for both compression and tension.

Since the adaptive suspension is not able to work independently, it has its own electronic control unit. Alteration of your own car in this case is associated with large material costs.

Plus, not every mechanic can understand the operation of the system, because in addition to mechanical elements, it contains a large number of electronic devices. They must be correctly connected to the control unit so that the device correctly records signals from all sensors.

Optimal performance

Choosing a new car, each motorist evaluates the handling and the amount of ground clearance of the proposed purchase. The presence of air suspension allows the owner of such a vehicle, without additional intervention in the design of the car, to change these parameters depending on the operating conditions.

When adjusting the chassis, the driver can focus on handling, or he can make the car as comfortable as possible. It is also possible to achieve a middle ground between these parameters.

If your car is equipped with a powerful powertrain, but its full potential cannot be used on public roads, you can adjust the suspension so that in normal operation the car is as soft and comfortable as possible. But as soon as the driver gets to the racetrack, you can activate the sport mode by changing the suspension settings as well.

Vehicle appearance

Although manufacturers offer new car models with already low ground clearance, such vehicles are ineffective in many regions. For this reason, very low models occupy only a small niche in the global car market. As for tuning, then in the direction stens autothe height of the car is very important.

Most often, self-lowered cars are obtained as a result of alteration of the chassis, because of which the transport loses its practicality. Today there are few people who are willing to invest heavily in a separate car, which will only be designed to put on a show at an auto show, and the rest of the time just gathering dust in the garage.

Air suspension allows you to underestimate transport as much as possible, but raise it if necessary. Usually, at the entrances to a gas station or an overpass, low cars suffer from the fact that they are not able to overcome a slight slope of the roadway. The adjustable design allows the driver to make the car unique without compromising its practicality.

Vehicle loading

Another useful feature of the air suspension is that it makes loading / unloading the machine easier. Some owners of SUVs with variable ground clearance have appreciated this option.

To overcome off-road conditions, most large-sized vehicles receive large wheels, which makes it much more difficult for a motorist with a short stature to put a load in the trunk. In this case, the machine can be lowered slightly. Similarly, you can use this system on a tow truck. During loading, the body height can be minimal, and during transportation, the owner of the tow truck raises the vehicle to a height that is comfortable for driving.

How to install air suspension with your own hands?

When the entire air suspension kit is purchased, the manufacturer provides detailed installation instructions along with all components. Also included in most kits is a repair kit.

This is a very important factor on which the competent installation of the system depends. Unfortunately, when installing complex mechanisms and various systems, even as complex as air suspension, many motorists turn to the instructions when something has already broken or the system is not working properly.

To prevent illiterate installation, which may cause some parts to fail, some companies warn that if the installation instructions are not followed, the system will be voided. And there are those who use psychological techniques. For example, the company alone prints the warning label “Do not open!” on the packaging of the system components. As conceived by marketers, this warning encourages buyers to first open the instructions, if only to understand why the packaging should not be opened. And the Ride Tech company prints this inscription on the instructions itself, counting on the fact that “forbidden fruit is always sweet” and the buyer will open the package with the ban first.

No matter how complex the system is, you can install it yourself, because even in the best service center or studio, people do this work. So, it is possible for a motorist. The main thing is to closely follow the manufacturer's instructions. In addition, the installer needs to understand how the system should work.

Depending on the type and complexity of the system, it can take 12-15 hours to install (for suspension components with cushions) + 10 hours to install the compressor and its components + 5-6 hours for the equalization system, if present in this system. But it depends on the motorist's skills in working with tools and knowledge of the technical part of the car. If you install the air suspension yourself, this will significantly save money (the installation cost is approximately a quarter of the price of the kit).

In order for the system to work properly, the use of sealing materials cannot be neglected. Air lines often leak if you don't use sealing tape on the connections. It is also necessary to isolate the line from the effects of mechanical damage and exposure to high temperatures. The final stage is the correct configuration of the system.

Air balloon design

The North American company Firestone is engaged in the production of high-quality pneumatic bellows. Its products are often used by truck manufacturers. If we conditionally classify these products, then there are three types of them:

- Double. This modification is adapted for poor road surfaces. Outwardly, it looks like a cheeseburger. This cushion has a short stroke. It can be used on the front of the suspension. In this part, the shock absorber is located close to the point of maximum load.

- Conical. These modifications are not fitted as front shock absorbers, although they have a longer travel. Their work has a linear principle, and they withstand loads less than the previous ones.

- Roller. These air bellows are also smaller than the double cushions (they have a thin, tall bulb). Their operation is almost identical to the previous modification, therefore, similar air shock absorbers are also installed on the rear of the car bogie.

Here is a drawing of the most common air suspension connection diagram:

Consider how the air spring is arranged.

Компрессоры

For the air spring to be able to change its height, it must be connected to an external air source. It is impossible to create one pressure in the system once, and the machine will be adapted to different operating conditions (number of passengers, weight of cargo, condition of the roadway, etc.).

For this reason, pneumatic compressors must be installed on the vehicle itself. This allows you to change the characteristics of the car right on the road, and in some models even while driving.

The pneumatic system will consist of at least one compressor, a receiver (a container in which air accumulates) and a control system (we will consider their modifications a little later). An economically viable and simplest modification is to connect one compressor and a 7.5-liter receiver. However, such an installation will lift the car for a couple of minutes.

If there is a need for the suspension to lift the car in just a couple of seconds, then you need at least two compressors with a capacity of 330 kg / square inch and at least two receivers with a volume of 19 liters. It will also require the installation of industrial pneumatic valves and pneumatic lines for 31-44 inches.

The advantage of such a system is that the car rises immediately after pressing the button. However, there is also a significant drawback. This design does not allow fine tuning - the car rises either too high or not enough.

Pneumatic lines

An integral part of all air suspension systems is a plastic air line designed for trucks. This is a high pressure line that makes it possible to connect all the components of the system. These modifications are capable of withstanding pressures ranging from 75-150 psi (psi).

If a more efficient pneumatic system is installed, for greater confidence, instead of a plastic line, you can use a metal analogue (it is used in brake systems). Standard flare nuts and adapters can be used to connect all components. The system components themselves are connected to the main line using flexible high pressure hoses.

Front suspension

The first development of pneumatic systems received mechanisms with which it was possible to slightly displace the front shock absorber. The reason is that the air spring does not have the area for the shock absorber, as in the MacPherson strut (it is located inside the spring).

The air spring kit for the front suspension includes special brackets that can be used to offset the shock without sacrificing performance. However, if non-standard large rims are installed in a small car (such tuning is popular nowadays) with low-profile tires, the use of air suspension in some cases will be impossible. For details on how to choose low-profile tires, see separately.

Recent developments include integrated air shock absorbers that replace the classic strut. This modification is significantly more expensive, but such mechanisms are much easier to install.

Before deciding on this modification, it is worth considering that on some chassis it is less effective than systems in which the air spring and shock absorber are separate. Sometimes, with a reduced clearance due to the design of the chassis, the wheel clings to the wheel arch liner while driving. In this case, a more rigid shock absorber is required.

For this reason, for those who primarily value maximum comfort, and not just a visual change in their transport, it is better to stay on a separate system.

Rear suspension

At the rear of the bogie, the installation of the pneumatic system depends on the type of car suspension. If there are MacPherson-type racks, and the design is multi-link, then it will not be difficult to install the cylinders on the stock support. The most important thing is to find the right modification. But when using a combined modification (the shock absorber and the cylinder are combined into one module), it may be necessary to slightly alter the car's suspension structure.

If there is a leaf spring suspension on the rear axle in the car, then the pneumatics can be installed in two ways. Before changing the suspension, please note that all leaf springs cannot be dismantled. The reason is that, in addition to the spring effect, these elements stabilize the rear axle. If you completely remove all the springs, you will need to install a lever system, and this is a serious intervention in the design of the car, which requires considerable engineering experience.

So, the first way to install air bellows on a spring suspension. We leave a few sheets on each side so that they continue to perform the function of stabilizing the axis. Instead of the removed sheets (between the body and the springs), an air bag is installed.

The second method is more expensive. Usually it is used by those car owners who want to maximize the "pump" of the car's suspension. All springs are removed and a 4-point airbag structure is installed on each side instead. For this modernization, many manufacturers have already created special kits of fasteners that allow you to install pneumatics with minimal welding.

Two types of levers are offered for the 4-point retrofit:

- Triangular. These parts are used on passenger cars for everyday use.

- Parallel. Such elements are used in trucks. If a passenger car is used for drag racing (the features of these competitions are described here) or other types of auto-competitions, the same type of levers is used.

Pneumocylinders

These elements are now made of rubber or high-strength polyurethane. This material has great elasticity and strength, which ensures the tightness of the system. Also, these materials are resistant to adverse weather conditions, mechanical stress while driving (sand, dirt and stones hit all the parts located under the bottom of the car), vibrations and chemicals that sprinkle the road in winter.

Buyers of pneumatic systems are offered three types of cylinders:

- Double. In their form, such cylinders resemble an hourglass. Compared to other analogues, this type of cylinders has great horizontal flexibility;

- Conical. They have the same properties as other air springs. Only their shape allows you to install such elements in a limited space. The disadvantage of this type is the small range of adjustment of the vehicle's ride height;

- Roller. These air bellows are designed for use in special conditions. Such cylinders are selected when installing a specific suspension design and the need to adjust a certain car height parameter. When purchasing a kit, the manufacturer will indicate which types of cylinders are recommended for use in a particular case.

Solenoid valves and pneumatic lines

In order for the air suspension to work, in addition to the cylinders, the system must have pneumatic lines and locking mechanisms (valves), since the pillows rise and hold the weight of the car due to the air pumped into them.

Pneumatic lines are a system of high pressure pipes that are laid under the bottom of the car. Although in this part of the car the line is exposed to the aggressive effects of reagents and moisture, it cannot be laid through the passenger compartment, because in the event of a depressurization, it will not be necessary to completely disassemble the entire passenger compartment for repairs.

The most reliable highway is made of non-ferrous metals, but there are also modifications made of polyurethane and rubber.

Valves are necessary for pumping and holding air pressure in a specific part of the line. These are the key elements that control the entire pneumatic system. The first air suspension received a double-circuit type. The disadvantage of such systems was the free movement of air from the compressor to the cylinders and vice versa. When entering a turn, due to the redistribution of the vehicle's weight in such systems, the air from the loaded cylinders was squeezed out into a less loaded circuit, which greatly increased the roll of the car.

Modern pneumatic systems are equipped with a number of valves that maintain pressure in a particular suspension unit. Due to this, such a suspension is able to compete with analogues with spring damper elements. For more precise control of the system, solenoid valves are used, triggered by signals from the control module.

Control module

This is the heart of the air suspension. In the automotive systems market, you can find simpler modules, which are represented by a simple electronic switch. If desired, you can find a more expensive option that is equipped with a microprocessor with software installed in it.

Such a control module monitors signals from various sensors in the system and changes the pressure in the circuits by opening / closing valves and turning on / off the compressor. So that the electronics do not conflict with the software of the on-board computer or the central control unit, it is independent of other systems.

Receiver

A receiver is a container into which air is pumped. Due to this element, air pressure is maintained in the entire line and, if necessary, this reserve is used so that the compressor does not turn on so often.

Although the system can work completely freely without a receiver, its presence is desirable in order to reduce the load on the compressor. Thanks to its installation, the compressor will work less often, which will increase its working life. The supercharger will turn on only after the pressure in the receiver drops to a certain value.

Varieties by the number of contours

In addition to the design features and power of the actuators, there are two-circuit and four-circuit versions of all types of pneumatic suspensions. The first modification was used on hot rods in the second half of the 1990s.

Let's consider some of the features of these systems.

Double-circuit

In this case, two air bellows, mounted on the same axle, are interconnected. With regard to installation, such a system is easier to install. It is enough to install one valve on one axle.

At the same time, this modification has a significant drawback. When the car enters a turn at speed, the air from the loaded cylinder moved into the cavity of the less loaded one, due to which, instead of stabilizing the car, the body roll became even more. In light vehicles, this problem is solved by installing a transverse stabilizer of greater rigidity.

Four-circuit

Due to significant shortcomings of the previous pneumatic system, a four-circuit version is installed on modern cars. The connection formula has independent control of each bellows. For this, each pillow relies on an individual valve.

This modification resembles the roll compensation system for cars adapted for track racing. It provides a more accurate adjustment of the ground clearance depending on the position of the car body relative to the roadway.

Control systems

In most cases, a four-loop system will be powered by electronics. This is the only control option that allows you to change the state of the suspension in a small range. True, this system is much more difficult to install (you need to correctly connect all the required sensors with the control unit), and it costs much more.

As a budget option, the car owner can install a manual system. This option can be used both on a two-circuit and on a four-circuit system. In this case, a pressure gauge and a control button are installed on the center console to monitor the pressure in the line.

An expensive but more efficient option is to install an electronic regulator. This system uses solenoid valves that are electronically controlled. Such a modification will consist of a control unit, a set of sensors necessary to determine the position of the car and the degree of cylinder inflation.

Recent developments can be equipped with several control systems. Let's take a look at how each of them works.

Pressure measuring control system

In theory, this system determines the position of the air spring (the electronics adjusts to this parameter to determine the amount of clearance). Pressure sensors in the system transmit signals to the control unit, allowing the electronics to determine the ride height. But such a control system has a significant drawback.

If the car is well loaded (there are the maximum number of passengers in the cabin, and there is a heavy load in the trunk), then the pressure in the highway will surely jump. Based on the pressure sensors, the on-board computer will determine that the car is raised to the maximum height, but in fact it may be too low.

Such a control system is suitable for light vehicles, in which heavy loads are rarely transported. Even refueling to full tank capacity alters the vehicle's ride height control. For this reason, the automation will incorrectly set the ground clearance.

Also, the large error of this type of active control system depends on the maneuvers that the vehicle performs. For example, when a car makes a long corner, one side of the suspension is loaded more heavily. The electronics interpret this change as lifting one side of the car. Naturally, the body stabilization algorithm is triggered.

In this case, the loaded part of the line begins to descend, and more air is pumped into the unloaded part. Because of this, the roll of the car increases, and it will wobble when cornering. The dual-circuit system has a similar disadvantage.

Control system that controls clearance

More effective with respect to a large number of load variables on individual cylinders is one that captures the real distance from the underbody to the road surface. It excludes all errors characteristic of the previous version. Thanks to the presence of sensors that determine the response of the suspension to an increase in pressure in specific circuits, the electronics more accurately sets the clearance depending on the situation on the road.

Despite this advantage, such a control system also has a disadvantage. For adequate vehicle handling, it is important that the suspension stiffness is approximately the same. The difference in pressure between different air bellows should not exceed 20 percent.

But when the electronics are trying to align the car as much as possible, in some situations this difference exceeds this parameter. As a result, one part of the suspension is as stiff as possible, while the other is very soft. This adversely affects the handling of the machine.

Combined systems

To eliminate the errors and shortcomings of both control systems, combined control systems were created. They combine the advantages of both the one that controls the pressure in the circuits and the one that determines the amount of clearance. Thanks to this combination, in addition to monitoring the position of the vehicle itself, these systems also neutralize each other's work.

A similar control system was developed by Air Ride Tec. The modification is called Level Pro. In this case, the electronic control unit is programmed into three modes. Maximum, average and lowest car fit. Each of these modes allows you to use the car in different operating conditions, from track rides to off-road.

A set of pneumatic bellows and solenoid valves works both from automatic and manual modes. When the car approaches a speed bump, it will not rise on its own to overcome this obstacle. For this, the electronics must have a larger number of sensors that scan the road surface in advance. These systems are very expensive.

Modified systems

The systems listed above are adapted for conventional road cars. For trucks and professional sports cars, there are modified control systems that provide fast and accurate auto tuning of the vehicle.

On the practical side, it is better to install a specially designed ready-made kit on an SUV, pickup truck or powerful hot rod than trying to create an adaptive suspension yourself. In addition to the fact that such a development will take a lot of time, there is a high probability that the mechanic may incorrectly perform the calculations, and the suspension will not cope with the loads.

Choosing a ready-made kit, the car owner just needs to look at the list provided by the manufacturer: whether this product is suitable for this car model or not. It takes into account the distance between the wheels and the wheel arch liners, the dimensions of the ball joints, the amount of the variable axle catch and other parameters, on the basis of which the automation determines how much air must be pumped into the cylinders.

Features of operation

As already stated, the key feature of air suspension, regardless of its design, is its cost. Although modern systems are quite reliable and efficient, when they fail, their repair turns into a real headache and a "black hole" in the wallet.

If the car is equipped with open airbags, it is recommended to use a lift more often during car wash in order to thoroughly wash the dirt and sand under the cuffs. Attention must also be paid to the hoses of the air line - make sure that they do not fray. If an air leak appears, it must be eliminated as soon as possible, because frequent switching on will reduce the working life of the compressor.

Some believe that the frequency of changes in ground clearance or suspension stiffness should be minimized as much as possible. For such motorists, air suspension is not needed, and a standard suspension is enough for them. Any system has its own resource, no matter how hard you try to extend its service life. The presence of air suspension makes the machine versatile, profitable off-road and more maneuverable at high speeds.

Air suspension advantages and disadvantages

Any modernization of the factory components of a car has both a positive and a negative side of the coin. First, about the advantages of pneumatics:

- As a result of reworking the suspension of the car, neither the transmission nor the lubrication of all auto units suffers. In some cases, the geometry of the suspension itself changes slightly.

- The air suspension is able to maintain the height of the machine, regardless of its load. If the load is unevenly distributed over the body, the system will keep the vehicle as level as possible relative to the road.

- If necessary, the machine can be raised to overcome obstacles on the road. And for a visual change on a flat surface, the car can be underestimated as much as possible (while the minimum height can lead to accelerated wear of the pillows).

- Thanks to high-quality body stabilization when cornering, the car does not sway, which adds comfort during the trip.

- The pneumatic system is quiet.

- When installing air bellows together with the factory suspension, regular parts last much longer. Thanks to this, the schedule for repair work is significantly increased. In some cases, such a suspension is capable of moving up to 1 million km.

- Compared to a similar vehicle with a classic suspension, a vehicle equipped with pneumatics has a large carrying capacity.

Before deciding to upgrade your car's suspension by installing a pneumatic system, you need to take into account all the disadvantages of such an upgrade. And these disadvantages are significant:

- To install pneumatics on your car, you need to spend a decent amount on the purchase of all the necessary elements. In addition, funds should be allocated to pay for the work of a professional who can competently connect all nodes. If you plan to sell a car in the future, then in the secondary market, a cheap model upgraded in this way will cost much more than the price segment in which it is located. Basically, such systems are practical to use in freight transport or on models of the "Business" class.

- Such a system is very demanding on operating conditions. She is afraid of dirt, water, dust and sand. Keeping it clean will take a lot of effort, especially given the condition of today's roads.

- The airbag itself is not repairable. If, due to improper operation (for example, frequent driving with minimum ground clearance), it deteriorates, it will need to be replaced with a new one.

- The effectiveness of air springs decreases with the onset of frost.

- Also, in winter, pneumatic elements are exposed to the aggressive effects of reagents that are strewn with roads.

If the motorist is ready to put up with these shortcomings, then we can say with confidence that, in comparison with classical springs and shock absorbers, the pneumatic analogue (especially the latest developments) will be more effective. However, unfortunately, such a development is available only to wealthy motorists and residents of southern latitudes.

Additionally, watch a video review of the evolution and features of the air suspension:

Related videos

Here's a short video on how the air suspension works:

Watch this video on YouTube

Questions and answers:

What's wrong with air suspension? The complex design and poor maintainability of the units make it very expensive to repair and maintain. Its resource is greatly influenced by weather conditions, road chemicals and freezing temperatures.

How does an air suspension compressor work? The piston reciprocates in the liner. The suction and discharge valves open alternately. The air flows through the dehumidifier into the working tank.

How does air suspension work on a truck? First, the braking system is filled with air. Then it is pumped into the air springs, and then it is pumped into the receiver. Air from the receiver is used to change the damping hardness.