Timing chain or valve train chain - what is it and when to change?

Content

- Differences between a timing chain and a belt

- Types of timing chains

- Replacement Recommendations

- Useful Tips

- Timing Chain Replacement: Step by Step

- Symptoms of a damaged timing chain

- Timing chain replacement frequency

- Where is the timing chain

- Choosing a new timing chain

- Manufacturers Tour

- Timing chain advantages

- Disadvantages of the timing chain drive

- Timing chain resource on a turbocharged and naturally aspirated engine

- Questions and answers about the timing chain:

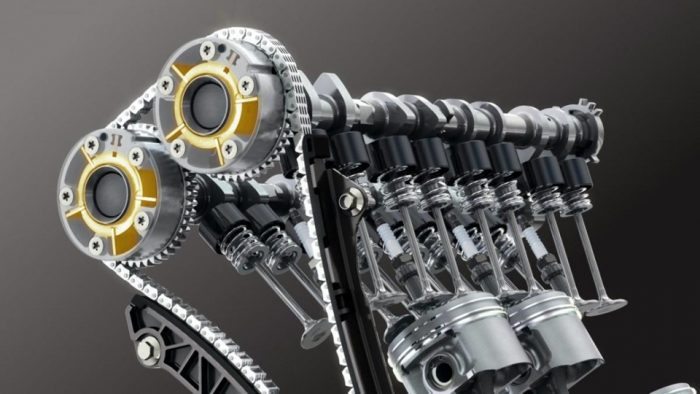

The timing chain is part of a car's engine, and its role is to synchronize the rotation of the crankshaft and camshaft at the bottom and top of the engine. This helps the engine's intake and exhaust valves open and close synchronously at precisely defined intervals with each engine revolution. The timing chain is also called - Valve Gear Chain.

In general, it acts as a connecting link between the upper part of the engine (cylinder head and valves) and the lower part (pistons and crankcase). This element looks like a chain in a bicycle and makes more sound than a timing belt.

Proper synchronization between the valve timing and the strokes occurring in the cylinders is a prerequisite for providing good power and overall engine performance, as well as fuel economy.

Since the crankshaft of four-stroke engines rotates twice as fast as the camshaft, a system is needed to synchronize them. This system can be of several types and include several different elements:

- Timing belt for connecting shafts;

- Gear transmission;

- The timing chain connecting the teeth of the camshaft and crankshaft pulleys.

Consider these systems: their advantages and disadvantages:

Gear There is a lot of noise in direct gear and internal power loss occurs. This type of system prevailed in the early 20th century.

Chain drive. The timing chain makes a quieter sound than direct transmission, but makes more noise than the timing belt. The disadvantage of the timing chain is that it stretches after a certain mileage. As this chain stretches, you can hear scratching and banging sounds, as well as a mismatch between opening and closing valves and ignition. Damage to the timing chain tensioner may cause it to generally decline during engine operation.

Belting. Timing belts, on the other hand, are common in cars with modern engines. They emit less noise compared to chains and direct transmission. They also have less friction, which helps to achieve less engine power loss. The life of the belts depends on the materials from which they are made.

They are made of synthetic rubber and have additional Kevlar fibers, which do not allow the belt to stretch, and also provide proper synchronization, which allows to increase mileage.

Differences between a timing chain and a belt

One of the main differences between the timing chain and the timing belt is that the timing chain can cause more damage in the event of a breakdown than the timing belt. When the timing chain breaks, it causes irreparable damage to the engine, which subsequently becomes practically unusable.

Another difference between the timing chain and the belt is that the chain tensioners are controlled by the oil pressure in the engine. Since good timing chain lubrication depends on the quality of the oil, it is important to change it periodically. If its level drops sharply, the tensioners will be blocked, and the timing chain will also be damaged.

The advantage of such a synchronization system is that it does not interact with the water pump, and therefore we do not need to replace the water pump with the timing chain.

In its function, it resembles a timing belt, but is more durable. Although some manufacturers claim that the timing chain may become obsolete with the car itself, others recommend frequent replacement.

Types of timing chains

In the process of evolution of drives of gas distribution mechanisms, many different modifications of drive elements have appeared, including chains. Today there are two types of chain drives:

- Plate and roller. As the name implies, rollers are included in the device of such a chain. They are connected to each other using plates and pins. A pinion tooth is inserted between each roller link, so that the sprocket engages the chain and transfers torque from the crankshaft to the camshaft. In this category of chains, there are modifications with one and two rows of links. The second type of plate roller chains is mainly installed on powerful motors with low crankshaft speeds.

- Lamellar. This type of chain is the result of the creation of motors capable of transmitting torque only at high rpm. The lamellar chain device includes a block of lamellas, which is connected to the adjacent one by means of a pin. When the plates are bent, an angular recess is formed in them at the inner radius, into which the sprocket tooth enters and engagement occurs.

Compared to plate-roller chains, the plate analog has a significantly longer service life. Also, this category of circuits makes much less noise during operation. The only caveat is that they are very demanding on the quality of the engine oil.

Replacement Recommendations

Manufacturers recommend changing the chain periodically - after about 100-200 km. A more precise regulation depends on the model of the car and the quality of the chain used. Timely replacement of the timing chain ensures optimal engine performance. This procedure will also prevent engine damage (in some cars, when the circuit breaks, the piston bends the valves, which leads to a major overhaul of the motor).

It is recommended to replace the chain together with the rollers, tensioner and gears, since it is not recommended to put on a new timing chain on already worn rollers. It is best to take all the elements in the kit to avoid the possibility of incompatible parts.

When the timing chain breaks at low speed, it can simply slip off the pulleys and not cause serious damage. But if it breaks at high engine speeds, the chain will damage everything that is nearby. The consequences are difficult to describe in advance, since during a rush, the chain can fly into several parts and touch various attachments. After that, the car can be repaired, but it will cost not at all cheap.

Warning signs of damage to the timing chain are poor engine performance and detonation. Unlike this element, the timing belt does not show any preliminary signs of damage, and its rupture occurs suddenly, after which the valves are bent and the pistons are destroyed, which guarantees us an expensive repair.

For these reasons, proper and timely maintenance is important and prevents engine damage.

Useful Tips

It is recommended to regularly check the condition of the drive in accordance with the manufacturer's instructions, and also strictly observe the timing intervals for replacing the timing chain.

When replacing the timing chain, care must be taken as this also determines how the engine will work. If the timing chain is not installed correctly, the engine will also not work properly. Repair must be done accurately.

Drive elements must always be changed in accordance with the recommendations for our car. Buying quality parts will certainly extend the life of the timing chain.

Timing Chain Replacement: Step by Step

The chain replacement procedure includes the following actions:

- Dismantling of protective covers;

- Gearbox lock;

- Chain replacement;

- Replacement of dampers and chain tensioners;

- Replace the oil pump if necessary;

- Installation of protective covers.

Symptoms of a damaged timing chain

A malfunction of the timing chain can damage the crankshaft and camshaft, pistons, cylinder walls.

One of the signs of damage to the timing chain is a knock that cannot be ignored, as well as loss of power, difficulty in ignition, and idling. Another sign of an extended timing chain is power loss.

When the timing chain is damaged, it will disrupt the engine. Because of this, fuel consumption can increase, as well as the level of harmful substances in the exhaust air.

Loosening the timing chain may damage other components located in close proximity.

Excessive tension and possible rupture of the timing chain may cause some problems, such as damage to the engine valves. If the timing chain is broken, the engine will not be able to start.

Also, damage to the timing chain may cause the engine to overheat. Since the water pump is driven by the synchronization circuit, loosening the synchronization circuit disrupts the operation of the water pump.

When the tooth on the gear breaks, the chain can slip, which causes the valve timing to shift and the valves may come into contact with the pistons. This damages the piston crown and causes the valves to bend, resulting in serious engine repairs.

If during the test we notice that the timing chain is very tight, it is better to replace it with a new one until it breaks. It is important to know that improperly installing the timing chain can also cause serious engine damage.

Since replacing the gas distribution chain has many nuances (you need to correctly set the position of the crankshaft and camshaft), it is recommended that you entrust this work to a professional service center.

Timing chain replacement frequency

As indicated by most car manufacturers, the timing chain is installed for the entire period of the vehicle's operation. However, this engine element has the ability to stretch. For this reason, the chain tension must be checked periodically. This function is performed by the tensioner, which wears out over time.

If the tensioner is new, but the chain is already well stretched, then it needs to be replaced. If this is not done, then during the operation of the motor, due to the high load, the drive can slip one or two links. This malfunction, in the case of some motors, can cause damage to the pistons and valves due to their collision (the moment has shifted when the piston is at top dead center and all valves are closed).

Timing chain stretching is indicated by an increase in noise during engine operation. Due to the displacement of the valve timing, the power unit will be unstable or will not be able to start at all.

Of course, you should not bring the motor to this state. In many auto models, the chain runs from 100 to 170 thousand kilometers. But if the car is carefully operated, then the chain replacement interval can be increased to 200 thousand. The main thing is to monitor its tension. But if the car has traveled about 250 thousand, then you need to plan work to replace the chain, even if it visually looks normal. Microcracks in the metal or damage to one of the pins is extremely difficult to detect, and this will sooner or later lead to rupture of the timing drive element.

Where is the timing chain

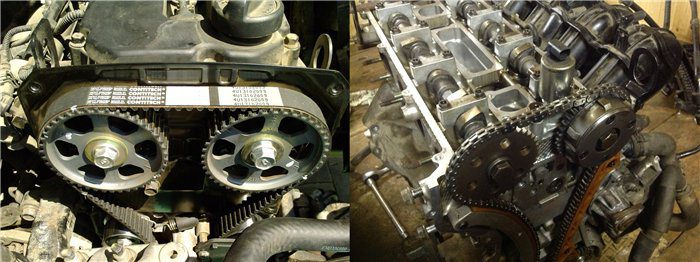

Of all the modifications of power units equipped with a gas distribution mechanism, there are two main types according to the location of the timing drive:

- Front. This is the classic layout used in most car models. In this case, the chain is located on the opposite side of the flywheel, that is, where the drive of the water pump, air conditioner and generator is located. The advantage of this design is that it is easier to maintain and replace the drive.

- Rear. In this design, the timing mechanism is located on the same side as the flywheel. The disadvantage of this arrangement is that it is extremely inconvenient to even visually inspect the chain without removing it from the motor. Despite the fact that the rear arrangement of the chain is not practical, this option is still used, moreover, by well-known car manufacturers, for example, BMW, as well as Audi.

Choosing a new timing chain

As with the selection of other parts, there are several ways to find a new timing chain. The first way is to search in a car dealership for a car model. In this case, the seller must provide the date of manufacture of the machine, the parameters of the power unit. If the model is running, then this information is enough for the auto shop employee, and he will quickly find a suitable option.

It is much better to search for a new drive element by VIN number. Where it is located, and what information about the car it contains, there is separate review... In this case, it can be guaranteed that a high quality and suitable chain will be purchased.

If you perform an independent search in the electronic catalog, then you need to carefully enter all the data about the car. Most of the Internet resources provide reliable information about the parts sold, but for the sake of confidence, it is better to contact trusted companies. They can be recognized by the number of products sold, as well as by customer reviews.

Here's a little trick to make it easier to find cheaper options. On some Internet sites, in addition to the VIN-code data, the catalog number is indicated in the tables. If the price of such a chain is too high, you can search other online stores. In some catalogs, only the catalog number is indicated. In this case, you can specify the number that is written in the table of the previous site.

Manufacturers Tour

Now let's talk a little about manufacturers. As with other parts, there are two types of chains: original and non-original. The overwhelming majority of car manufacturers complete their models with third-party products. But these are only proven companies that pay enough attention to the quality of the manufactured products. These manufacturers' products can be found in auto parts stores.

But in the case of timing chains, it should be borne in mind that in most cases these elements will be sold together with other spare parts for the timing mechanism drive (damper, tensioner, various seals, sprockets and a shoe).

Here are some manufacturers who sell decent products:

- German INA;

- Swedish SKF;

- Japanese DID;

- English BGA;

- German IWIS;

- American Dayco.

You can also find good quality kits sold by packaging companies. Among them SWAG and Febi are German companies. Do not trust those manufacturers who offer goods at a "seductive" price. Often such chains have a small working life and break quickly.

Timing chain advantages

Chain-driven gas distribution mechanisms have been used in automobiles for a long time. For this reason, some motorists mistakenly believe that this option is an ancient development and for a modern car it is a relic of the past. In fact, this is not the case. Today, automakers such as Mitsubishi, BMW and Toyota use this type of gas distribution mechanisms in some car models.

If we compare a belt drive with a chain drive, then the second has the following advantages:

- Minimal mechanical damage due to high load on the motor;

- Great working resource. As we have already said, if you properly take care of the motor and tighten the chain in time, then it can go up to 250 thousand kilometers;

- The operation of the chain does not depend on the ambient temperature (at high loads and low temperatures, the belt may be damaged);

- The chain does not stretch as quickly. This only happens when the end of the service life is approaching;

- Resistant to temporary overload.

Disadvantages of the timing chain drive

Despite the listed advantages of the timing chain, this modification still has its drawbacks. Here are just a few of them:

- The motor weighs more than the belt drive. For civilian cars this is not critical, but for sports cars this parameter is one of the most important (some automakers invest thousands of dollars in the development of vehicles in order to "win back" an additional couple of tens of kilograms);

- The production of such power units is more expensive due to the complex design. The end consumer receives an expensive part as a result;

- The presence of additional parts in any mechanism increases the risk of malfunctions in it. The same applies to the gas distribution mechanism, more precisely, its drive;

- Due to the complexity of the design, the chain is more difficult to change - even to tighten it, it is necessary to dismantle the cover on the gas distribution mechanism (depending on the car model). If this work is carried out by a specialist at a service station, then the motorist will have to part with a decent amount of money;

- Compared to a belt drive, the chain still makes noise all the time the motor is running.

At the end of our review, we offer a short video about why chains break more often in modern cars than in old cars:

Timing chain resource on a turbocharged and naturally aspirated engine

The chain drive of the timing system can be installed on both atmospheric and turbocharged engines. On conventional, atmospheric power plants, there is no specific information regarding the exact timing of replacing the chain. Unfortunately, nothing is eternal in this world. However, according to some automakers - on cars with atmospheric engines, the timing chain resource, as a rule, is not limited, that is, it is designed for the entire life of the engine, and this, on average, is about 250-350 thousand kilometers of run. But that doesn't mean we shouldn't watch the chain.

As for engines equipped with a turbocharger, different rules apply here. It is known that turbo engines have more torque and effort, therefore, they are more powerful than atmospheric counterparts. That is why the chain mechanism in such motors has a different service life, usually less.

For reference - normal turbocharged engines have an average chain life of about 150-170 Thousands miles and more.

Questions and answers about the timing chain:

How often to change the timing chain. As indicated in the operating instructions for most car models, the timing chain, with proper maintenance, is designed for the entire life of the vehicle. The planned replacement of this element of the power unit is not provided. Basically, the chain changes as it wears out. Each car needs this at its own time. If we take into account the operating conditions in middle and temperate latitudes, then often the chain needs to be replaced after about 170 thousand kilometers.

How to determine timing chain wear. For this it is necessary to dismantle the valve cover. First you need to determine the degree of wear of the tensioner. If its wear can be estimated at about 70 percent, then it must be replaced. Backlash between chain links is also a bad symptom. Another possibility to determine the condition of the circuit is with a scanner, which will show incorrect signals from the camshaft sensor.

Does a stretched timing chain affect fuel consumption? Although the timing chain does not directly participate in the distribution of the valve timing, this moment depends on its condition. This is because stretching the links causes the phases to shift slightly. Naturally, this affects the stability of the internal combustion engine. To some extent, the reaction to pressing the gas pedal gets confused, which is why the driver needs to squeeze it all the way more often. As a result, the engine starts to consume more fuel.