What breaks down in diesel injection?

Content

The quality of fuel atomization, combustion, and even the power and torque of the engine depend on the operation of the injectors. So whenever you see symptoms of an injection failure in your vehicle, hurry to a mechanic. It is not worth tightening, because the longer you drive with faulty injectors, the more serious the consequences will be. Not sure how to recognize a malfunction and what can break down in the injectors? We are in a hurry to explain!

What will you learn from this post?

- What parts of the injection system are the most fail-safe?

- How to recognize a broken injector?

Shortly speaking

The most expensive and most intensively working element of the injection system is the pump, but fortunately, this is not the most emergency module. Injectors break down most often. Damage to them can be caused, for example, by poor condition of the seals, clogged needle holes or corrosion of the housing.

If you want to know how injectors work, read the previous entry in this series. → How does the diesel fuel injection system work?

Why do diesel injectors break?

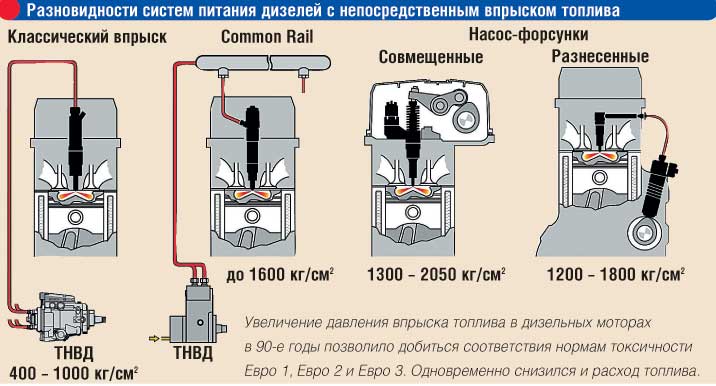

The injectors, although not adapted to this, are doomed to work in difficult conditions. These rather thin and precise devices feed diesel fuel under enormous pressure into the cylinders of the engine an infinite number of times while driving. Today the pressure in the injection system is from 2. bars up. Half a century ago, when the system became widespread, injectors had to withstand almost half the pressure.

Assuming the fuel quality is perfect, the injectors should run 150 km without any problems. kilometers. However, with diesel fuel, things can be different. For this reason, it happens that replacing the injectors is necessary more often than the manufacturer suggests. The service life is reduced to 100-120 km or less. Its reduction depends on the operating conditions of the engine and how you operate it.

What can break in the injectors?

Control valve seats. They are damaged by particulate matter in the fuel, usually sawdust. This causes the injector to leak, i.e. "Filling", as well as errors in determining the pressure of the hydroaccumulator rod. Seat wear can lead to uneven performance and even severe starting problems.

- Valve stems. Any damage to the spindle inside the injection - be it tarnishing due to insufficient lubrication, clogging or sticking due to sticking due to poor quality fuel - causes the injectors to leak and overflow. And here the consequence is uneven, inefficient operation of the engine.

- Sealants. Their wear is indicated by a noticeable smell of exhaust gases or a characteristic hiss or tick when the engine is running. Seals are made in the form of small round washers pressing the injector to the seat in the cylinder head. They cost a penny and replacing them is child's play, but not meeting deadlines can have serious consequences - exhaust gases exiting the injection chamber create obstructive gangrene. This will make it difficult to remove a damaged injector and may even force the entire cylinder head to be disassembled for this purpose. Repair in this case will be expensive and cumbersome.

- Spray holes. When the nozzle tip is worn out, spraying does not work properly. Fuel is not delivered accurately and instead drips from the tip at unscheduled times. The inadequacy of the diesel fuel supply to the needs leads to insufficient engine power under load, problems with reaching rpm, as well as increased fuel consumption and noisy operation. In Common Rail systems, clogging of holes with solid impurities from poor-quality fuel is, unfortunately, a frequent malfunction and can stop the car at the most unexpected moment.

- Needle. Both the wear of the cone of the moving needle inside the injector tip and its binding cause serious damage. Seizure occurs when using contaminated fuel that washes and lubricates the needle during operation. Who would have guessed that the failure of this small element could lead to the ingress of fuel into the engine oil, and in newer cars, even damage to the particulate filters?

- Pisoelectric element. On common rail engines, the coil can also be damaged. This is due to corrosion of the nozzle holder or a short circuit in the solenoid. It can also be caused by improper assembly or use of a part not in accordance with the manufacturer's recommendations.

How to recognize a malfunction of an injector?

Most often it reports a malfunction. black smoke comes from the exhaust pipe, especially when starting off and sharp acceleration. This is caused by too much fuel being supplied by the injector to the engine cylinders. This reduces engine power and increases oil consumption. The symptom of injection damage is also hard, knocking engine operation.

In Common Rail, injector malfunction diagnosis is more difficult than in other systems. When one of them starts to run unevenly, the others adjust their work in such a way as to keep the exhaust emissions within the normal range.

Problems with starting the car not only annoy you, but also they stress the battery and starter. While battery replacement is not a hassle, a broken starter requires costly repairs. Even worse for the wallet will be replacing the dual-mass flywheel, which wears out faster when it has to compensate for rpm fluctuations. And this is just the beginning of the problems that can arise if you ignore the symptoms of a failed injection. Their list is long: damage to the lambda probe, failure of the particulate filter, misalignment of the timing chain, and in extreme cases, even melting of the pistons.

Want to know more about diesel injectors? Read the rest of the series:

How does the diesel fuel injection system work?

How to care for diesel injectors?

And take care of the engine and other parts of your car at avtotachki.com. Visit us and find out what else you need to keep your diesel engine running like new.

avtotachki.com,