Test drive gasoline and diesel engines in single engines or HCCI engines: Part 2

Mazda says they will be the first to use it in the series

With clean gases like gasoline and the efficiency of diesel fuel. This article is about what happens when designing an ideal engine with homogeneous mixing and autoignition during compression. The designers simply call it HCCI.

Accumulation of knowledge

The foundations of such processes date back to the seventies, when the Japanese engineer Onishi developed his technology "Active combustion in the thermo-atmosphere". In the yard, 1979 is the period of the second oil crisis and the first serious legal restrictions of an environmental nature, and the engineer's goal is to bring two-stroke motorcycles common at that time into line with these requirements. It is known that in the light and partial load mode, a large amount of exhaust gases is stored in the cylinders of two-stroke units, and the idea of the Japanese designer is to turn its disadvantages into advantages by creating a combustion process in which residual gases and high fuel temperature mix for useful work. .

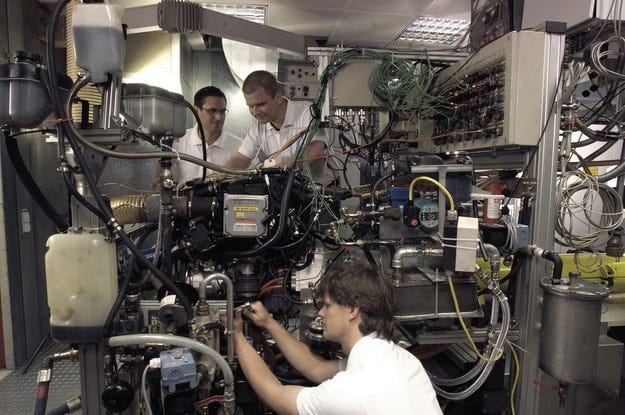

For the first time, engineers from the Onishi team were able to implement an almost revolutionary technology in itself, triggering a spontaneous combustion process that truly successfully reduced exhaust emissions. However, they also found significant improvements in engine efficiency, and soon after the development was unveiled, similar processes were demonstrated by Toyota, Mitsubishi and Honda. Designers were amazed by the extremely smooth and at the same time high-speed combustion in the prototypes, reduced fuel consumption and harmful emissions. In 1983, the first laboratory samples of four-stroke self-ignition engines appeared, in which process control in various operating modes is possible due to the fact that the chemical composition and ratio of components in the fuel used are absolutely known. However, the analysis of these processes is somewhat primitive, since it is based on the assumption that in this type of engine they are carried out due to the kinetics of chemical processes, and such physical phenomena as mixing and turbulence are insignificant. It was in the 80s that the foundations were laid for the first analytical models of processes based on pressure, temperature and concentration of fuel and air components in the chamber volume. The designers came to the conclusion that the operation of this type of engine can be divided into two main parts - ignition and volumetric energy release. Analysis of the research results shows that self-ignition is initiated by the same low-temperature preliminary chemical processes (occurring below 700 degrees with the formation of peroxides) that are responsible for harmful detonation combustion in gasoline engines, and the processes of releasing the main energy are high-temperature. and are performed above this conditional temperature limit.

It is clear that the work should be focused on the study and study of the results of changes in the chemical structure and composition of the charge under the influence of temperature and pressure. Due to the inability to control cold start and work at maximum loads in these modes, engineers resort to the use of a spark plug. The practical test also confirms the theory that the efficiency is lower when operating with diesel fuel, since the compression ratio must be relatively low, and at higher compression, the self-ignition process occurs too early. compression stroke. At the same time, it turns out that when using diesel fuel, there are problems with the evaporation of flammable fractions of diesel fuel, and that their pre-flame chemical reactions are much more pronounced than with high-octane gasolines. And one more very important point - it turns out that HCCI engines work without problems with up to 50% of residual gases in the corresponding lean mixtures in the cylinders. From all this it follows that gasolines are much more suitable for working in this type of units and developments are directed in this direction.

The first engines close to the real auto industry, in which these processes were successfully implemented in practice, were modified VW 1,6-liter engines in 1992. With their help, the designers from Wolfsburg were able to increase the efficiency by 34% at partial load. A little later, in 1996, a direct comparison of the HCCI engine to a gasoline and direct injection diesel engine showed that HCCI engines showed the lowest fuel consumption and NOx emissions without the need for expensive injection systems. on fuel.

What's going on today

Today, despite the downsizing directives, GM is continuing to develop HCCI engines, and the company believes that this type of machine will help improve the gasoline engine. The same opinion is held by Mazda engineers, but we will talk about them in the next issue. At Sandia National Laboratories, working closely with GM, they are currently refining a new workflow, which is a variant of the HCCI. The developers call it LTGC for "Low Temperature Gasoline Combustion". Since in previous designs, HCCI modes are limited to a rather narrow operating range and do not have much advantage over modern machines for size reduction, the scientists decided to stratify the mixture anyway. In other words, to create precisely controlled poorer and richer areas, but in contrast to more diesel. Events at the turn of the century have shown that operating temperatures are often insufficient to complete the oxidation reactions of hydrocarbons and CO-CO2. When the mixture is enriched and depleted, the problem is eliminated, since its temperature rises during the combustion process. However, it remains low enough not to initiate the formation of nitrogen oxides. At the turn of the century, designers still believed that HCCI was a low-temperature alternative to a diesel engine that did not generate nitrogen oxides. However, they are not created in the new LTGC process either. Gasoline is also used for this purpose, as in the original GM prototypes, as it has a lower vaporization temperature (and better mixing with air) but a higher autoignition temperature. According to laboratory designers, the combination of LTGC mode and spark ignition in more unfavorable and difficult to control modes, such as full load, will result in machines that are much more efficient than existing downsizing units. Delphi Automotive is developing a similar compression ignition process. They call their designs GDCI, for "Compression Ignition Direct Petrol Injection" (Gasoline Direct Injection and Compression Ignition), which also provides lean and rich work to control the combustion process. In Delphi, this is done using injectors with complex injection dynamics, so that, despite depletion and enrichment, the mixture as a whole remains lean enough not to form soot, and low enough temperature not to form nitrogen oxides. The designers control different parts of the mixture so that they burn at different times. This complex process resembles diesel fuel, CO2 emissions are low and the formation of nitrogen oxides is negligible. Delphi has provided at least 4 more years of funding from the US government, and the interest of manufacturers such as Hyundai in their development means they will not stop.

Let's remember Disotto

The development of the designers of the Daimler Engine Research Labs in Untertürkheim is called Diesotto and in start-up and maximum load mode it works like a classic gasoline engine, using all the advantages of direct injection and cascade turbocharging. However, at low to medium speeds and loads within one cycle, the electronics will turn off the ignition system and switch to self-ignition mode control mode. In this case, the phases of the exhaust valves radically change their character. They open in a much shorter time than usual and with a much reduced stroke - so only half of the exhaust gases have time to leave the combustion chamber, and the rest is deliberately kept in the cylinders, along with most of the heat contained in them. To achieve an even higher temperature in the chambers, the nozzles inject a small portion of fuel that does not ignite, but reacts with heated gases. During the subsequent intake stroke, a new portion of fuel is injected into each cylinder in exactly the right amount. The intake valve opens briefly with a short stroke and allows a precisely metered amount of fresh air to enter the cylinder and mix with the available gases to produce a lean fuel mixture with a high proportion of exhaust gases. This is followed by a compression stroke in which the temperature of the mixture continues to rise until the moment of self-ignition. Precise timing of the process is achieved by precisely controlling the amount of fuel, fresh air and exhaust gases, constant information from sensors that measure the pressure in the cylinder, and a system that can instantly change the compression ratio using an eccentric mechanism. changing the position of the crankshaft. By the way, the operation of the system in question is not limited to the HCCI mode.

Managing all of these complex operations requires control electronics that do not rely on the usual set of predefined algorithms found in conventional internal combustion engines, but allow real-time performance changes based on sensor data. The task is difficult, but the result is worth it - 238 hp. The 1,8-litre Diesotto guaranteed the concept F700 with S-Class CO2 emissions of 127 g/km and compliance with the stringent Euro 6 directives.

Text: Georgy Kolev

Home " Articles " Blanks » Gasoline and Diesel Engines in Single or HCCI Engines: Part 2