20 years of Common Rail for Diesel IIs: Alfa Romeo was the first

Continuation: The difficult path of designers to implement new technology.

They are the backbone of everything Fiat and Bosch

Soon after Fiat introduced the direct injection Croma in 1986, a similar system was introduced by Rover, who created it in collaboration with British specialists from Perkins. It will be used later for Honda models. It wasn't until 1988 that the VW Group had the first direct injection diesel engine, which also used a Bosch distribution pump. Yes, it is VW that plays the role of mass injector for direct injection in diesel vehicles. However, VW is so passionate about its TDI engines that it misses out on the revolution of the late 20th century. So, back to the beginning of the story, to meet again with the engineers of Fiat and Bosch. This time it's not about collaboration.

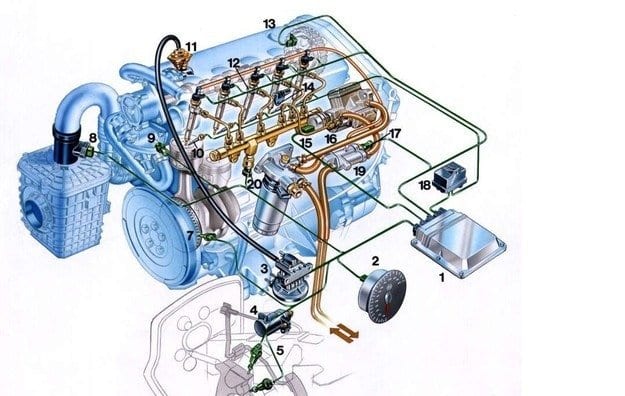

The aforementioned Centro Ricerce Fiat and Magnetti Marelli still managed to build a functional system in which the pressure generation process is separated from each other. This avoids pressure drops and achieves maximum pressure at high speeds. To do this, a rotary pump fills a thick-walled steel fuel rail. Direct injection is carried out using solenoid-controlled injectors. The first prototypes were created in 1991, and three years later the technology was sold to Bosch, who further developed it. The system, developed in this way by Fiat and refined by Bosch, appeared in 1997 in the Alfa Romeo 156 2.4 JTD and Mercedes-Benz E220 d. At the same time, the maximum injection pressure of 1360 bar still does not exceed the pressure of some of the previous systems (used by the Opel Vectra and the Audi A6 2.5 TDI from 1996 and the BMW 320d from 1998, the VP 44 pump for direct injection achieves a pressure in the range of 1500 - 1750 bar) , but process control and efficiency are at a much higher level.

Its biggest advantage is that it maintains a constant high rail pressure, which allows precise control of the injection, which in turn can now be delivered in batches - which is very important for the mixture in a diesel engine. Thus, the pressure is independent of speed, the quality of the combustion process is significantly improved, which means that fuel consumption and emissions are reduced. With the development of the system, electromagnetic injectors will be replaced by more accurate piezo injectors, allowing the use of a large number of short-term injections and pressures up to 2500 bar for cars and up to 3000 bar for trucks and buses in the latest generations of diesel engines.

Labor pains with Common Rail

Of course, even Fiat engineers don't start blindly. However, they have access to the work of both Vickers, who created a similar mechanical system many years ago, and the Swiss Federal Institute of Technology ETH, and in particular the team of Robert Hubert, who created a successful diesel prototype in the 60s. with Common Rail system and electronic control. Of course, the rudimentary electronic devices of those years allowed only prototypes to work in the laboratory, but in 1983, Marko Ganzer of ETH patented an "electronically controlled battery charging system" for diesel cars. In fact, this is the first promising development of such a system. After all, the problem is not in the idea, but in its implementation, and it is the engineers of Fiat and Bosch who manage to deal with all the problems associated with the high pressure leaks inherent in this technology, the creation of adequate injectors and other. It is a little known fact that although car manufacturers in Japan are lagging behind in the development of diesel engines, in fact the first vehicle to use Common Rail injection was a Hino truck with a J08C engine and Denso injection system, which is the result of the work of the teams of Dr. Shonei Ito and Masahiko Lighthouses. Equally interesting is the fact that in the 80s, engineers at the East German IFA successfully developed a similar system for their trucks.

Unfortunately, Fiat's financial problems in the late 90s forced him to sell his golden chicken to Bosch. After all, it was Bosch who developed this technology, and today it is the undisputed leader in the production of these systems. In fact, there are still few manufacturers of this equipment - in addition to Bosch, these are Denso, Delphi and Siemens. Under the hood and in whatever car you look, you will find something similar. Shortly after the Common Rail system demonstrated its advantages over everything else, it was introduced by the French manufacturers PSA. At that time, manufacturers such as Mazda and Nissan They had already introduced direct injection, but without the Common Rail system, VW continues to look for ways to create an efficient system that does not use Common Rail patents, and introduced a more common injector system for truck pumps in 2000. Indeed, in 2009, VW also did not give up and did not replace it with a common rail.

Truck manufacturers introduced it later - just a few years ago, their engines were also equipped with a pump-injector or so-called pump-pipe-injector with separate pump elements and a very short high-pressure tube. At the Tokyo show, Quon showed another interesting solution - pump-injector technology, which, however, is powered by a common thin-walled rail with lower pressure. The latter plays the role of an intermediate balancing node.

In addition to all of the above, the Common Rail system is fundamentally different from the pre-injection systems in that it is based on the kinetic energy generated by the pump for precise fuel injection. Thus, there is no need for such a high compression ratio, as well as the high level of turbulence, which is preferable for diesel engines with a prechamber and which is intensively created in diesel engines with a vortex chamber. The Common Rail system, together with the development of electronic control technology and turbochargers, created the preconditions for the diesel revolution, and without it, gasoline engines would have no chance today. By the way, the latter also received a similar filling system, only on a smaller order. But that's another story.

Yes, the Common Rail system is expensive and complex, but there is currently no alternative to diesels. Manufacturers have also managed to create cheaper, lower pressure options for low-cost vehicles like India, where diesel is respected. After the latest scandals, diesel was blamed for all earthly faults, but, as recent tests of the APP show, its cleaning is quite possible. In any case, interesting times lie ahead.

Text: Georgy Kolev